Transformers

Epoxy Resin Cast Dry-Type Transformer

1000kVA Dry Type Transformer

NPC ELECTRIC 1000kVA Dry-Type Transformer offers efficient, oil-free power distribution with a compact design. Equipped with advanced insulation and cooling systems, it ensures safe and reliable operation with minimal maintenance. Ideal for industrial and commercial applications, it provides environmentally friendly and cost-effective performance.

1250kVA Dry Type Transformer

NPC ELECTRIC 1250kVA Dry-Type Transformer delivers reliable, oil-free power distribution with a compact and efficient design. Featuring advanced insulation and cooling systems, it ensures safe, low-maintenance operation, making it ideal for industrial and commercial applications. It provides environmentally friendly, cost-effective performance with a 1250kVA capacity.

1600kVA Dry Type Transformer

1600kVA dry-type transformer is an efficient and reliable power equipment designed to provide a stable power supply. Its rated capacity is 1600kVA, which is suitable for the power needs of various industrial and commercial sites. The transformer adopts advanced dry insulation technology, which has higher safety and durability, and avoids the fire hazards that may be caused by oil-immersed transformers. In addition, the low-noise operation and environmentally friendly design of the equipment can effectively reduce operating costs and reduce environmental impact.

2000kVA Dry Type Transformer

The NPC ELECTRIC 2000kVA Dry Type Transformer is a robust and efficient power solution designed to handle the electrical needs of large-scale industrial and commercial operations. With a capacity of 2000kVA, it features advanced dry-type insulation, ensuring enhanced safety, minimal maintenance, and long-lasting performance. This transformer is built to operate reliably in various environmental conditions while offering low noise levels and a reduced environmental footprint.

2500kVA Dry Type Transformer

The NPC ELECTRIC 2500kVA Dry Type Transformer is a high-capacity, reliable power solution designed for large industrial and commercial applications. With a power rating of 2500kVA, it features advanced dry-type insulation technology, offering superior safety, low maintenance, and long-term performance. Engineered to operate efficiently in demanding environments, this transformer delivers stable, noise-free power while minimizing environmental impact.

3000kVA Dry Type Transformer

3000kVA Dry Type Transformer is a high-performance, reliable power solution designed to meet the needs of large industrial and commercial facilities. With a 3000kVA capacity, it utilizes advanced dry-type insulation, ensuring exceptional safety, minimal maintenance, and extended durability. Built for demanding environments, this transformer provides stable, efficient, and low-noise operation while minimizing environmental impact. The NPC ELECTRIC 3000kVA Dry Type Transformer is the ideal choice for ensuring reliable and efficient power distribution in large-scale applications.

5000kVA Dry Type Transformer

The NPC ELECTRIC 5000kVA Dry Type Transformer is a high-capacity, reliable power solution designed for large-scale industrial and commercial operations. With a robust 5000kVA rating, it features advanced dry-type insulation technology for enhanced safety, low maintenance, and long-lasting performance. Engineered for demanding environments, this transformer ensures stable, efficient, and quiet operation while minimizing environmental impact.

6300kVA Dry Type Transformer

The NPC ELECTRIC 6300kVA Dry Type Transformer is a high-performance, heavy-duty power solution designed for large industrial and commercial applications. With a capacity of 6300kVA, it features cutting-edge dry-type insulation technology, offering superior safety, low maintenance, and extended reliability. Built to withstand demanding operating conditions, this transformer provides stable, efficient, and noise-free performance while minimizing environmental impact.

7500kVA Dry Type Transformer

7500kVA Dry Type Transformer is a high-capacity, reliable power solution designed for large-scale industrial and commercial applications. With a robust 7500kVA rating, it incorporates advanced dry-type insulation technology, ensuring enhanced safety, minimal maintenance, and exceptional durability. Engineered for demanding environments, this transformer delivers stable, efficient, and low-noise operation while reducing environmental impact. The NPC ELECTRIC 7500kVA Dry Type Transformer is the ideal choice for high-power applications, providing secure and continuous power distribution for critical infrastructure.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, transformers exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High-efficiency Core Design

High magnetic permeability and low loss silicon steel sheets are used and processed by special process to reduce hysteresis loss and eddy current loss and improve conversion efficiency.

Multiple Protection Systems

IP65 protection grade design combines multiple protection measures such as anti-corrosion, anti-UV, anti-condensation and anti-small animal intrusion.

Ultra-low Noise Technology

A special shock-absorbing structure, low-noise fans, and optimized heat dissipation design ensure operating noise is far below industry standards.

Intelligent Cooling System

The heat dissipation system with adaptive temperature control automatically adjusts the heat dissipation efficiency according to the load and ambient temperature to reduce energy consumption.

Safety Wiring System

Insulated protective cover and anti-misoperation design ensure personnel safety during installation and maintenance and reduce accident risks

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

Dry type transformers have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Seismic Resistance Level

IEC 60068-2-57

Suitable for earthquake-prone areas

Altitude

≤3000m

More than special design

Why Choose Us

Superior Fire Safety & Eco-Friendly

Robust Insulation & Mechanical Strength

Minimal Maintenance & Humidity Proof

Compact Footprint for Easy Installation

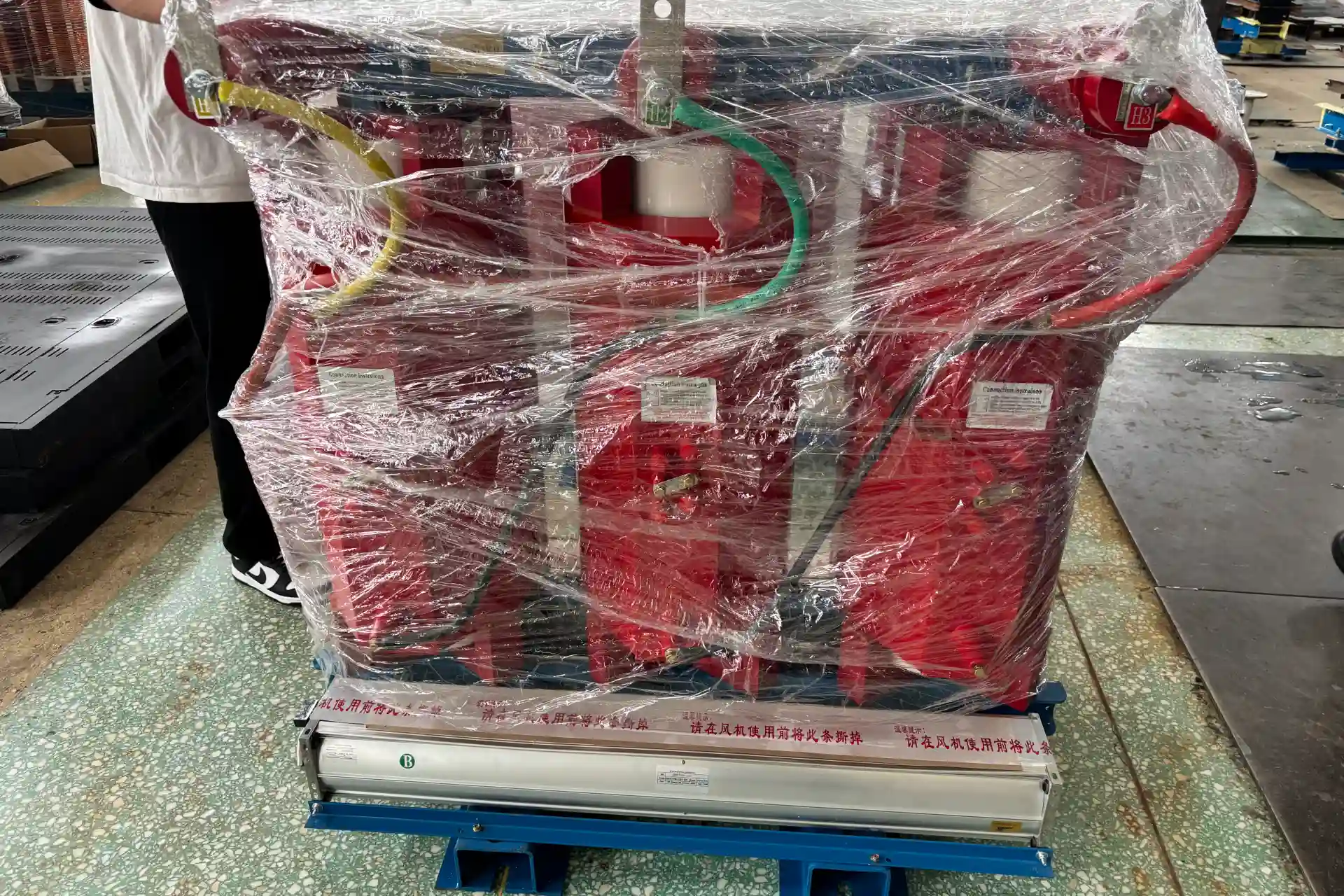

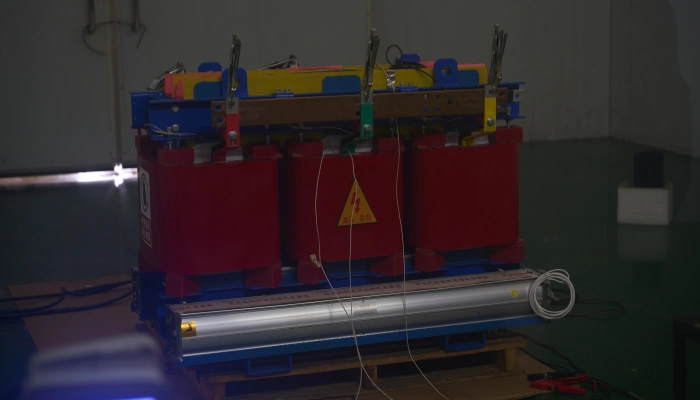

Product Show

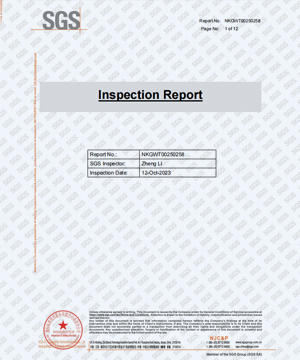

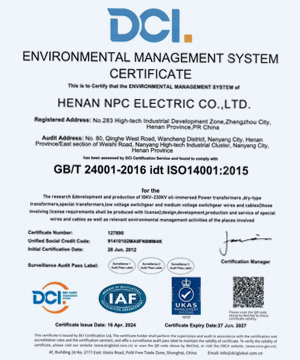

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

ISO Environmental Certificate

ISO Occupational Certificate

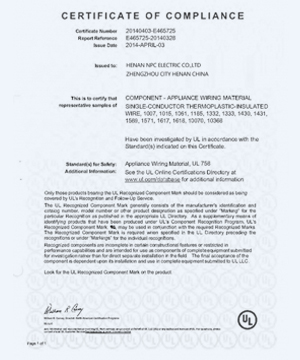

UL Laboratory Certificate

UL Product Certificate

Project Cases

Venezuela Residential Area

CompletedProvide stable and reliable power conversion solutions for the residential area to meet diverse production needs.

Country:Venezuela

Model:75kVA Dry Type Transformer x 20

Rwanda Data Center

CompletedEnsure the power safety of surrounding residents and meet daily work needs

Country:Rwanda

Model:167kVA Dry Type Transformer x 15

Panama Factory

CompletedNPC transformers provide safe, efficient, and reliable power distribution in Panama.

Country:Panama

Model:150kVA Dry Type Transformer x 30

Technical Advantages

FAQ From Customers

-

How to test a dry type transformer?

Testing a dry type transformer involves several procedures to ensure electrical and mechanical reliability. Common transformer testing methods include insulation resistance measurement, turns ratio testing (TTR), winding resistance, and dielectric strength tests. For cast resin dry type transformers, partial discharge and temperature rise tests are also essential to detect insulation degradation. NPC Electric conducts all tests according to IEC 60076 and IEEE C57.12 standards to guarantee optimal performance and long service life of each dry type distribution transformer. -

Do dry transformers require a special enclosure?

Yes, dry type transformers may require a special enclosure, depending on their installation environment. For indoor installations, ventilated enclosures ensure proper cooling and dust protection. For outdoor dry type transformers, weatherproof or IP-rated enclosures protect against moisture, corrosion, and debris. NPC Electric offers custom dry type transformer enclosures designed for industrial, marine, and renewable energy applications, ensuring safe operation and compliance with IEC and ANSI protection standards. -

What are the faults of dry type transformers?

Common dry type transformer faults include insulation breakdown, overheating, winding deformation, and partial discharge. These issues often result from overloading, poor ventilation, or contamination from dust and moisture. Regular transformer testing and maintenance help identify and prevent such faults early. NPC Electric’s cast resin dry type transformers are engineered with advanced insulation systems and thermal protection to minimize fault risks and enhance long-term reliability. -

How to maintenance a dry type transformer?

Proper maintenance of a dry type transformer includes periodic inspections, cleaning, and monitoring of temperature, load, and insulation condition. Dust and debris should be removed from ventilation openings to prevent overheating. For cast resin dry type transformers, regular visual inspections can detect cracks or discoloration. Electrical testing such as insulation resistance and partial discharge tests should be performed annually. Following manufacturer guidelines ensures maximum reliability and extended service life for any dry type distribution transformer. -

How to ground a dry type transformer?

Grounding a dry type transformer is essential for electrical safety and system stability. The transformer’s core and enclosure must be connected to the facility’s grounding system using approved copper conductors. The neutral of the secondary winding is typically grounded to prevent overvoltage during faults. Proper grounding ensures safe operation, minimizes electrical shock hazards, and protects equipment from lightning or transient surges. NPC Electric designs all dry type transformers in compliance with IEC and IEEE grounding standards for safe and efficient operation.