How to Maintain and Repair Wires and Cables: A Technical Guide for Professionals

Wires and cables are ubiquitous in modern life and production, providing a reliable foundation for people's lives and the backbone of modern electrical and communication systems. For technicians, understanding how to properly maintain and repair wires and cables is crucial to ensuring safety, reliability, and efficiency. This guide will introduce practical methods for wire and cable inspection, preventative maintenance, fault detection, and repair procedures to help you achieve optimal operational performance.

1. Understanding Wires and Cables

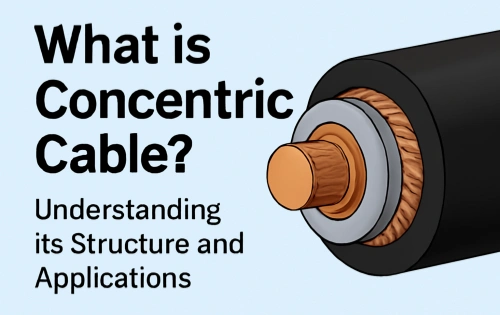

Before diving into maintenance and repair, technical staff must understand the basic structure and types of wires and cables.

- Electrical Wires: Single conductors, usually copper or aluminum, used to carry current between two points.

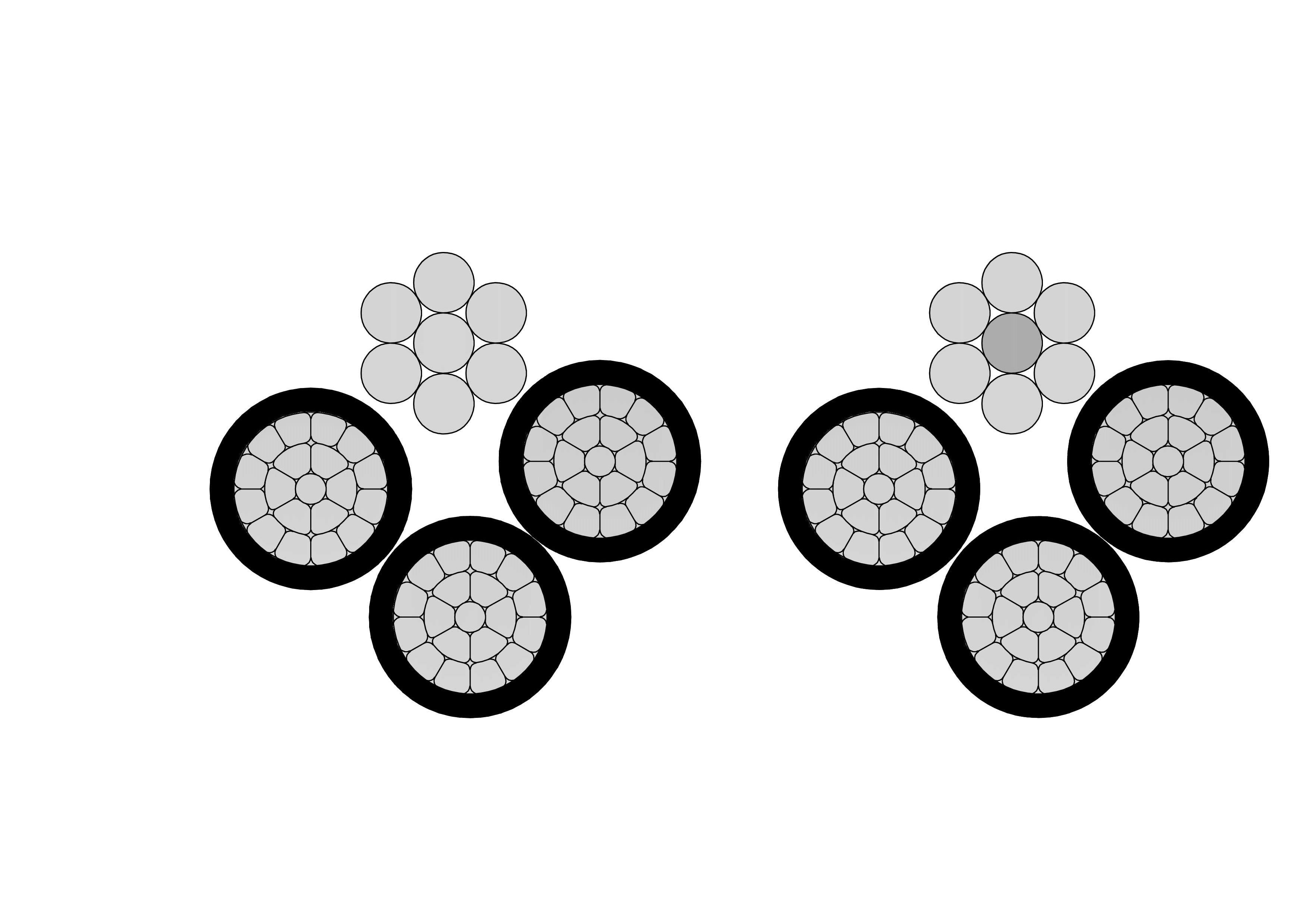

- Electrical Cables: Assemblies of multiple conductors insulated from each other, designed for power or data transmission.

- Best Wires and Cables Selection: Choose based on voltage rating, current capacity, environmental conditions, and applicable standards (such as IEC, NEC).

- Wire and Cable Your Way: Customizing wire and cable configurations to match specific project requirements can reduce waste and improve performance.

2. Importance of Maintenance for Wires and Cables

Neglecting maintenance wires and cables can lead to system downtime, electrical hazards, and costly repairs. Proper maintenance ensures:

- Safety: Prevents electrical shocks, fires, and short circuits.

- Longevity: Reduces premature aging of insulation and conductors.

- Efficiency: Minimizes energy losses due to poor connections or damaged conductors.

For critical applications, such as industrial automation or data centers, maintaining the best wires and cables is a non-negotiable requirement.

3. Inspection and Preventive Maintenance Procedures

3.1 Visual Inspection

Regularly check for:

- Cracks, cuts, or abrasions on insulation.

- Discoloration indicating overheating.

- Loose or corroded connectors.

- Physical deformation caused by mechanical stress.

3.2 Electrical Testing

Technical staff should use:

- Insulation Resistance Testers (Meggers): To measure insulation integrity.

- Continuity Testers: To confirm conductor integrity.

- Thermal Imaging Cameras: To detect hotspots caused by excessive resistance.

3.3 Environmental Control

- Keep cables away from sources of heat, chemicals, or excessive moisture.

- Use cable trays and conduits to protect against mechanical damage.

- Ensure proper ventilation for high-current electrical cables.

4. Common Wire and Cable Problems

Some of the most frequent issues in electrical wires and cables include:

- Insulation Damage – Often caused by rodents, UV exposure, or excessive bending.

- Connector Failures – Loose connections increase resistance and heat.

- Corrosion – Particularly in marine or humid environments.

- Overloading – Operating beyond rated current leads to insulation breakdown.

- Mechanical Stress – Frequent movement or vibration can fracture conductors.

5. Repair Techniques for Wires and Cables

When damage is detected, repair must follow safety regulations and professional standards.

5.1 Splicing and Joining

- Twist and Solder: For low-voltage electrical wires, solder joints can restore continuity.

- Crimp Connectors: Provide mechanical strength and conductivity for medium-duty repairs.

- Heat-Shrink Tubing: Adds insulation and strain relief after joining conductors.

5.2 Insulation Repair

- Use self-fusing silicone tape or specialized cable repair sleeves.

- For high-voltage electrical cables, apply multi-layer insulation with stress control materials.

5.3 Connector Replacement

- Replace damaged plugs, terminals, or lugs with rated components.

- Ensure torque specifications are met for secure connections.

5.4 Full Section Replacement

In cases of severe damage or multiple faults, replacing an entire section of wire and cable is safer than patch repairs.

6. Safety Guidelines for Maintenance and Repair

- Always disconnect power before working on wires or cables.

- Use personal protective equipment (PPE) such as insulated gloves, safety glasses, and flame-resistant clothing.

- Follow local electrical codes and standards.

- Use lockout/tagout (LOTO) procedures to prevent accidental energization.

7. Extending the Service Life of Electrical Wires and Cables

To ensure the best wires and cables last as long as possible:

- Avoid Excessive Bending: Maintain proper bend radius per manufacturer specifications.

- Reduce Load Stress: Operate below 80% of rated capacity for long-term reliability.

- Protect from UV Exposure: Use UV-resistant jackets or conduit outdoors.

- Perform Scheduled Maintenance: Document inspection results and schedule follow-ups.

- Wire and Cable Your Way: Choose materials and designs that match environmental and mechanical conditions.

In Conclusion, for technical professionals, mastering maintenance wires and maintenance cables is not just about fixing problems—it’s about preventing them. By implementing systematic inspection, testing, and repair protocols, you can ensure that electrical wires and cables operate safely and efficiently for years.

Investing time in proper maintenance and repair techniques will reduce downtime, improve performance, and enhance safety—making it an essential skill set for any electrical technician.