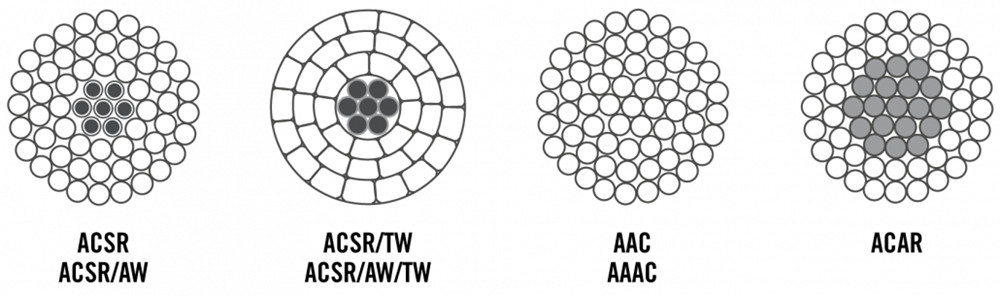

Complete Guide to AAC, AAAC, ACSR, and ACAR Conductors – Types, Features, and Applications

Overhead power lines form the backbone of modern electrical grids, ensuring efficient transmission of electricity from power plants to end users. A critical component of these systems is the overhead conductor, which must deliver high performance, durability, and reliability under diverse environmental conditions. Among the most commonly used types of bare conductors are AAC, AAAC, ACSR, and ACAR. Each conductor type is engineered to meet specific technical and operational requirements, making it essential for engineers, utility companies, and project managers to understand their differences, advantages, and applications.

1. What is an Overhead Conductor?

An overhead conductor is an uninsulated cable, typically strung between transmission towers or poles, that carries electrical power across long distances. Unlike underground cables, overhead conductors are exposed to the environment, requiring them to withstand mechanical stress, wind load, ice accumulation, and temperature variations.

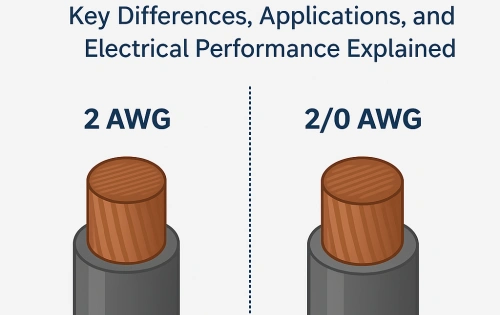

Bare conductors are usually made of aluminum or aluminum alloys, sometimes reinforced with steel for extra strength. Aluminum is favored because of its lightweight nature, good conductivity, and cost-effectiveness compared to copper.

The four major types we will cover—AAC, AAAC, ACSR, and ACAR conductors—represent different design approaches to meet diverse mechanical and electrical needs.

2. AAC Conductor (All Aluminum Conductor)

Definition and Composition

The AAC conductor (All Aluminum Conductor) consists of stranded aluminum wires without any reinforcement or alloy content. It is made from EC-grade aluminum, known for excellent conductivity and low weight.

Key Features

- High conductivity: Nearly equivalent to pure aluminum.

- Lightweight: Easy to handle and install.

- Corrosion resistance: Performs well in urban and coastal areas.

Applications

AAC conductors are widely used in urban overhead power lines, short spans, and areas where mechanical strength is not the primary concern. Because they lack steel reinforcement, they are not suitable for long spans or regions prone to strong winds or heavy ice.

3. AAAC Conductor (All Aluminum Alloy Conductor)

Definition and Composition

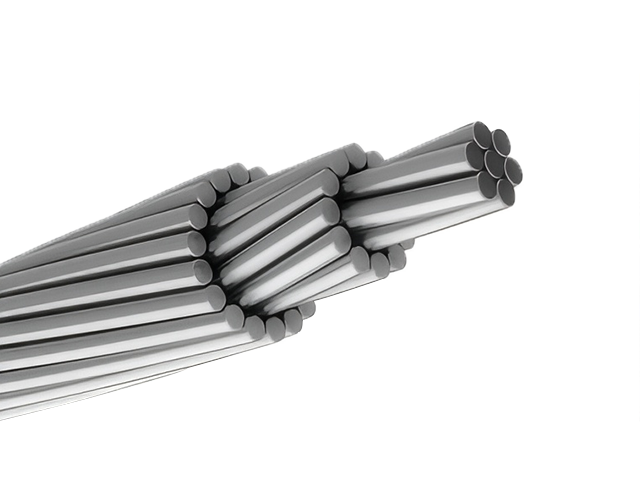

The AAAC conductor is made from aluminum alloy 6201-T81, which combines aluminum with small amounts of magnesium and silicon. This enhances strength without significantly reducing conductivity.

Key Features

- Higher strength-to-weight ratio than AAC.

- Improved corrosion resistance, especially compared to ACSR.

- Good conductivity, though slightly less than AAC.

Applications

AAAC is often used in medium to long-span overhead power lines, especially in areas with high wind load or coastal environments. Its corrosion resistance makes it ideal for saline regions and industrial atmospheres.

4. ACSR Conductors (Aluminum Conductor Steel Reinforced)

Definition and Composition

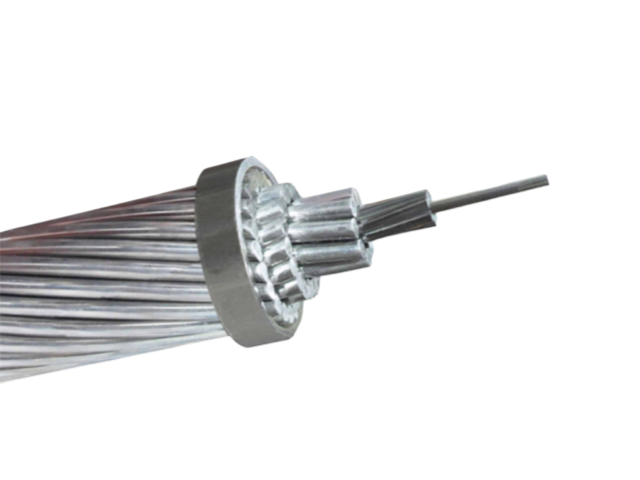

ACSR aluminum conductor steel reinforced cable consists of stranded aluminum wires wrapped around a steel core. The steel provides mechanical strength, while the aluminum ensures high electrical conductivity.

Key Features

- Exceptional tensile strength, ideal for long spans.

- Cost-effective for high-voltage transmission due to reduced sag.

- Available in various designs to balance strength and conductivity.

Applications

ACSR conductors are the preferred choice for long-distance transmission lines, river crossings, and areas with heavy ice or strong winds. However, the steel core may corrode, so galvanization or special coatings are often used.

5. ACAR Conductors (Aluminum Conductor Alloy Reinforced)

Definition and Composition

The ACAR conductor combines the benefits of aluminum alloy strength and high conductivity. It consists of stranded aluminum wires reinforced with aluminum alloy wires, instead of steel.

Key Features

- Higher strength than AAC and AAAC, but lighter than ACSR.

- Excellent conductivity and reduced sag compared to ACSR.

- Superior corrosion resistance due to the absence of steel.

Applications

ACAR conductors are widely used in extra-high-voltage (EHV) transmission systems where a balance of strength, conductivity, and corrosion resistance is required.

6. AAC vs AAAC vs ACSR vs ACAR – Key Differences

|

Feature |

AAC |

AAAC |

ACSR |

ACAR |

|

Material |

Pure aluminum |

Aluminum alloy (6201-T81) |

Aluminum + Steel core |

Aluminum + Aluminum alloy core |

|

Strength |

Low |

Medium |

High |

High |

|

Corrosion Resistance |

Excellent |

Excellent |

Moderate (steel may corrode) |

Excellent |

|

Conductivity |

Highest |

Slightly lower |

Lower than AAC & AAAC |

Comparable to AAC |

|

Applications |

Short spans, urban lines |

Coastal & windy regions |

Long spans, heavy load areas |

EHV lines, corrosion-prone areas |

7. Choosing the Right Conductor for Your Project

The selection of an overhead conductor depends on several factors:

- Span length: Longer spans often require ACSR or ACAR.

- Environmental conditions: Coastal or industrial areas benefit from AAAC or ACAR.

- Budget constraints: AAC is often the most economical choice for short spans.

- Electrical load and voltage level: Higher voltage and load require stronger conductors like ACSR or ACAR.

Understanding the differences between AAC conductors, AAAC conductors, ACSR conductors, and ACAR conductors is crucial for designing reliable overhead power line systems. Each type—whether AAC all-aluminum conductor, aluminum alloy conductor, or ACSR aluminum conductor steel reinforced cable—offers unique advantages in terms of mechanical strength, conductivity, and corrosion resistance.

As the demand for efficient and sustainable transmission networks grows, selecting the right conductor will continue to play a key role in ensuring power stability and cost efficiency across global grids.

3GHSSYCY-mining-cable-2.webp)

2Y-high-voltage-power-cable-2.webp)