Wires and Cables

Guard Wire

Galvanized Steel Conductor

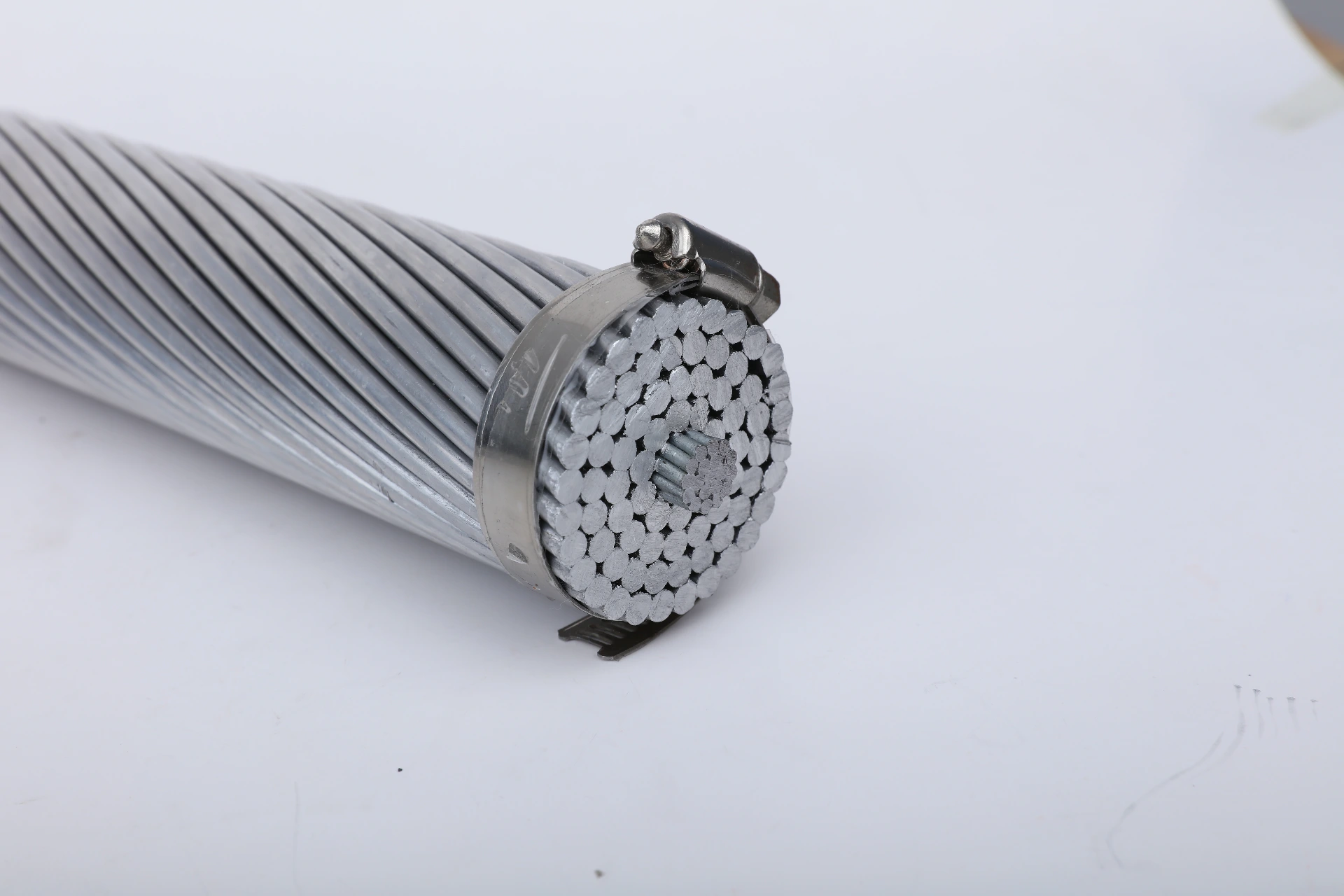

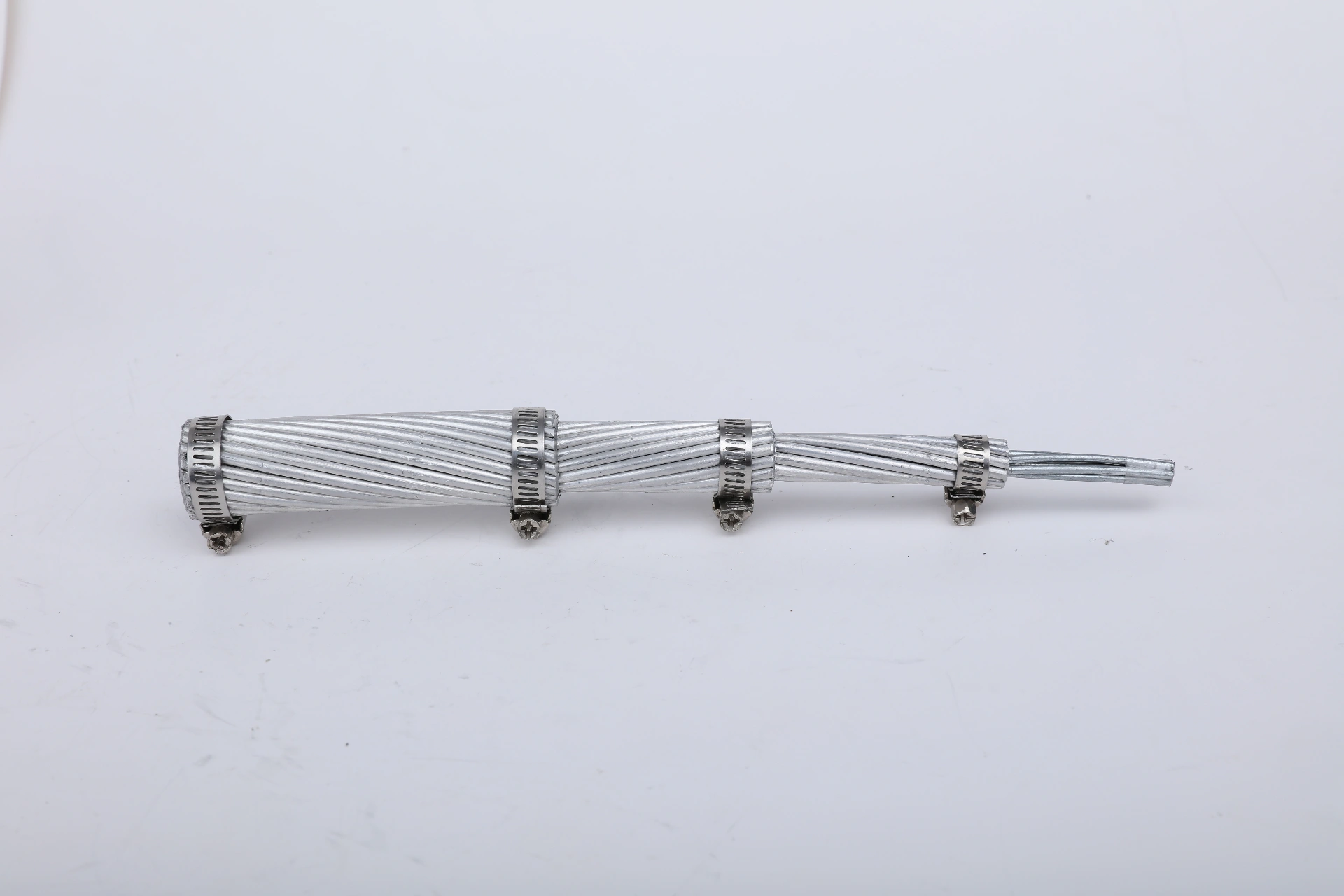

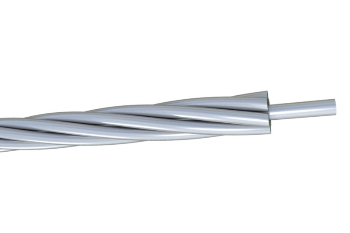

The Galvanized Steel Conductor Cable Guard Wire offers robust mechanical protection for overhead power systems. Constructed from premium high-tensile steel wires with Class A or B hot-dip galvanization, it delivers exceptional resistance to rust, abrasion, and environmental stress. Meeting standards like ASTM A475 and BS EN 50189, this guard wire provides high breaking strength and flexibility for spanning long distances. Installed as an overhead shield, it prevents damage to conductors from external impacts, reducing downtime and maintenance costs. The uniform zinc layer ensures decades of service life even in coastal or polluted areas. Select our Galvanized Steel Conductor Cable Guard Wire for reliable overhead line guarding in electric utilities, telecommunications, and infrastructure projects worldwide.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, guard wire exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

Guard wire have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

Lightning Protection & Grid Resilience

Integrated OPGW for Smart Grid

Durability & Corrosion Resistance

Compliance & Custom Engineering Support

Product Show

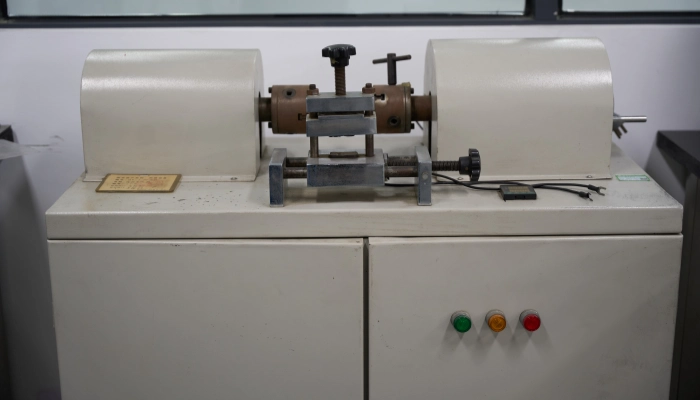

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

ISO Environmental Certificate

ISO Occupational Certificate

UL Laboratory Certificate

UL Product Certificate

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

Model:NPC AAAC Cable & Triplex Cable x 10km

Technical Advantages

FAQ From Customers

-

What are guard wires used for in power transmission?

Guard wires are safety wires installed above or alongside power transmission lines to protect conductors from damage caused by external factors like lightning strikes, tree branches, or animals. Made from galvanized steel conductor or similar materials, guard wires help minimize electrical outages and enhance electrical safety by preventing direct contact with high-voltage lines. They are particularly useful in areas prone to environmental risks, ensuring reliable and uninterrupted power delivery. -

What is a galvanized steel conductor?

A galvanized steel conductor is a type of steel conductor coated with a layer of zinc to improve its resistance to corrosion. These galvanized conductors are commonly used in overhead power lines, guard wires, and grounding systems, as they offer high strength and durability in harsh weather conditions. The galvanization process helps prevent rust and extends the lifespan of the conductor, making it ideal for outdoor and industrial applications. -

What is the difference between guard wires and conductors?

Guard wires and conductors serve different purposes in power transmission systems. Guard wires are primarily installed for safety and protection against external factors, while conductors carry electrical current. Guard wires are usually made from galvanized steel conductor for high strength and corrosion resistance, while conductors (like AAC, ACSR, or AAAC) are designed to efficiently transmit electricity over long distances. Guard wires protect the electrical network, while conductors ensure power is distributed. -

Why are galvanized steel conductors preferred for guard wires?

Galvanized steel conductors are preferred for guard wires due to their high tensile strength and corrosion resistance. The zinc coating on the steel helps protect the conductor from rust and deterioration, especially in harsh environmental conditions such as high humidity, coastal areas, or extreme weather. The durability of galvanized steel makes it an ideal choice for overhead power lines and guard wires, ensuring long-term performance and reduced maintenance costs. -

What are the advantages of using galvanized steel conductors in power transmission?

Galvanized steel conductors offer several key advantages in power transmission lines. They provide excellent tensile strength, making them ideal for long-distance overhead power lines where support is needed for large spans. The galvanization process also ensures corrosion resistance, allowing them to withstand exposure to harsh weather conditions. Galvanized steel conductors are highly durable, low-maintenance, and cost-effective, making them a popular choice for both guard wires and transmission cables in industrial and utility applications.