Galvanized Steel Wire (GSW) Cable: Applications, Benefits, and Key Features Explained

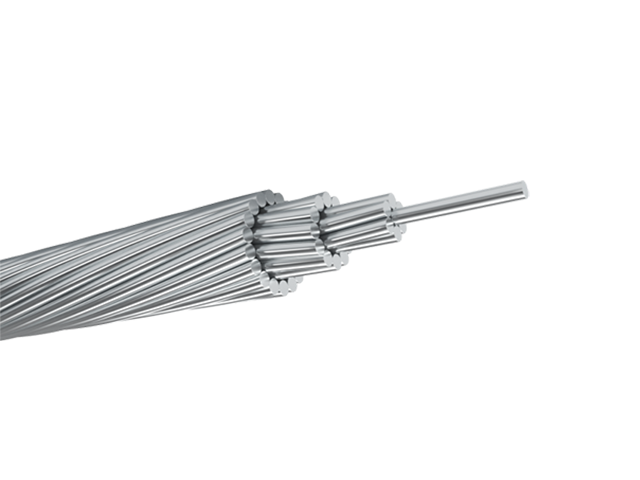

Galvanized Steel Wire (GSW) Cable is an essential component used in various electrical and telecommunication applications. It consists of a steel core that is coated with a layer of zinc to enhance its corrosion resistance and provide long-lasting durability. The zinc-coated steel wire, in particular, offers significant improvements in both the strength and longevity of electrical transmission and distribution systems.

GSW cables are commonly used in overhead lines, ground wires, stay wires, and guy wires. These wires are particularly vital in overhead ground systems, transmission lines, and steel core cables for power and communication. As wire and cable manufacturers continue to innovate in materials, GSW cable offers a cost-effective and reliable solution for modern electrical grids and infrastructure.

1. Key Features and Benefits of GSW Cable

a. High Strength and Durability

One of the most significant advantages of GSW galvanized steel wire is its high strength. The steel core provides the necessary tensile strength required for overhead line applications, including transmission lines and high-voltage systems. This makes GSW cable ideal for long-distance power transmission and supporting heavy electrical loads.

The zinc coating also helps prevent corrosion, which can significantly reduce the lifespan of wires in outdoor environments. The galvanized steel wire strand is known for its robustness against environmental factors such as UV radiation, wind, and rain, ensuring that the cables last longer with minimal maintenance.

b. Corrosion Resistance

The corrosion resistance of GSW cables is a key feature that makes them stand out in industries where exposure to moisture, chemicals, or pollutants is common. Galvanized steel wire strands are coated with zinc, which forms a protective barrier against rust and corrosion. This makes them particularly suitable for outdoor applications, where environmental exposure is inevitable.

GSW cables are compliant with IEC 61089 standards, which ensures that these cables maintain their durability and performance even in the harshest environments. The corrosion-resistant properties of these cables make them a preferred choice for use in overhead ground and transmission lines, where longevity is a key factor.

c. Compliance with Industry Standards

GSW cables are designed to meet various industry standards, such as BS 183 and IEC 61089, which regulate the mechanical properties, corrosion resistance, and insulation characteristics of wires and cables used in electrical systems. These standards ensure that GSW cables perform reliably and efficiently under different conditions.

The zinc-coated wires used in GSW cables also adhere to BS 183 standards, ensuring that the diameter and strength of the wire meet the necessary requirements for heavy-duty applications like overhead lines and transmission lines.

2. Applications of GSW Cable

a. Overhead Ground and Stay Wires

GSW cables are widely used as overhead ground wires and stay wires in transmission line installations. These cables provide grounding for electrical systems and ensure the safety of both the infrastructure and the environment. In case of a fault in the system, the ground wire directs excess electrical current to the ground, preventing damage to equipment and reducing the risk of fires.

Stay wires are used to support transmission towers, providing additional strength to the structural framework of the power grid. The high strength of GSW cables makes them an ideal choice for these critical applications.

b. Transmission Lines and Guy Wires

GSW galvanized steel wire is also a key component in transmission lines, where it acts as a guy wire to stabilize transmission towers and ensure the proper tension and alignment of the power lines. Guy wires are essential for maintaining the structural integrity of transmission towers, especially in areas prone to high winds or heavy snow.

By using galvanized steel wire strands, these guy wires are resistant to corrosion, ensuring they perform effectively in demanding conditions. They can withstand high tensile stress without breaking, making them an integral part of high-voltage power transmission lines.

c. Grounding Systems for Power Distribution

GSW cables play a crucial role in the grounding systems of power distribution lines. These cables provide a reliable pathway for electrical currents to flow safely to the ground in the event of an overload or fault in the system. Grounding is a critical safety measure that protects both equipment and individuals working with electrical systems.

The steel core provides the necessary tensile strength to maintain the stability of grounding systems over time, while the zinc coating helps prevent corrosion, ensuring the long-term effectiveness of the grounding system.

3. Advantages of GSW Cables Over Other Types of Cables

a. Cost-Effectiveness

While GSW cables are more expensive than some alternatives, they offer a significant return on investment over time. Their high strength and corrosion resistance reduce the need for frequent maintenance and replacement, making them more cost-effective in the long run. This is especially true for outdoor applications where exposure to the elements is a concern.

b. Eco-Friendly and Sustainable

GSW cables are considered environmentally friendly due to their corrosion-resistant zinc coating. Unlike other types of cables that may require chemical treatments or additional coatings, zinc-coated cables are durable, sustainable, and require less frequent replacements. This contributes to the environmentally friendly nature of GSW cables, making them an excellent choice for eco-conscious projects.

c. Better Performance in Harsh Environments

Oil-immersed transformers and other cables may suffer from degradation over time in harsh environments, but GSW cables excel in extreme weather conditions. Whether in coastal areas exposed to saltwater, high altitudes, or regions with fluctuating temperatures, the corrosion resistance and high tensile strength of GSW cables make them ideal for use in these conditions.

4. Conclusion

Galvanized Steel Wire (GSW) Cables are a critical component in the design and construction of modern electrical power systems. Their high strength, corrosion resistance, and compliance with industry standards make them a reliable and cost-effective choice for a wide range of electrical transmission lines, distribution lines, and grounding systems.

From overhead ground wires to guy wires and stay wires, GSW cables provide the structural support and safety necessary for power systems to operate efficiently and safely. Their environmentally friendly properties and long-term durability make them an essential part of any modern electrical grid.

By choosing GSW cables for your power systems, you're investing in a solution that offers reliability, longevity, and cost-effectiveness for years to come.

5. FAQ

1. What is Galvanized Steel Wire (GSW) Cable?

Answer:

Galvanized Steel Wire (GSW) Cable is a type of wire made from steel coated with a layer of zinc. This coating provides excellent corrosion resistance, making it ideal for overhead lines, transmission lines, and ground wires in outdoor applications. GSW cables are often used in power systems for high strength and durability.

2. What are the primary applications of GSW cables?

Answer:

GSW cables are commonly used in overhead power lines, stay wires, guy wires, and grounding systems for both transmission lines and distribution networks. Their corrosion resistance and high tensile strength make them suitable for outdoor applications in harsh environments, such as coastal areas or regions with extreme weather conditions.

3. How does the zinc coating on GSW cables protect them?

Answer:

The zinc coating on GSW cables acts as a protective barrier that prevents rust and corrosion from damaging the steel wire. This makes them highly suitable for outdoor installations, as the coating helps extend the lifespan of the cables, even when exposed to moisture, salt, and other corrosive environmental factors.

4. What is the difference between GSW cables and traditional copper wires?

Answer:

Unlike traditional copper wires, GSW cables use steel as the core material, which gives them higher tensile strength. The zinc coating on the steel wire provides superior corrosion resistance compared to copper, making GSW cables a more cost-effective solution for overhead lines and grounding systems. Additionally, GSW cables are less prone to damage under mechanical stress.

5. What are the benefits of using GSW cables in overhead ground systems?

Answer:

GSW cables offer several key benefits in overhead ground systems, including:

-

High strength to support high-voltage transmission lines and distribution networks.

-

Corrosion resistance, making them ideal for outdoor installations where environmental exposure is high.

-

Durability with minimal maintenance requirements, reducing operational costs over time.

These attributes make GSW cables the preferred choice for stay wires, guy wires, and ground wires in power systems.

6. Are GSW cables suitable for indoor applications?

Answer:

While GSW cables are primarily designed for outdoor use due to their corrosion resistance and strength, they can also be used in indoor applications where high tensile strength and mechanical support are required, such as in building grounding systems. However, for strictly indoor uses, dry-type cables or other cable types with better insulation might be preferred.

7. How does the cost of GSW cables compare to other types of cables?

Answer:

While GSW cables may have a higher initial cost compared to some non-galvanized wires, their long lifespan, low maintenance requirements, and superior corrosion resistance make them a cost-effective choice over time. They are ideal for high-strength applications in environments where corrosion could significantly reduce the lifespan of standard wires.

2Y-high-voltage-power-cable-2.webp)