Wires and Cables

Wires and Cables

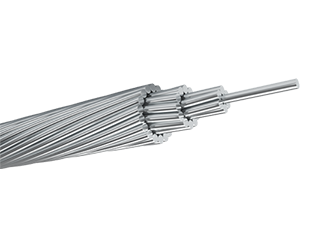

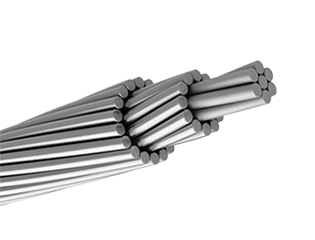

ALL ALUMINUM ALLOY CONDUCTORS(AAAC)

All Aluminum alloy (ALMELEC) electrical wire conductors are made from high-strength Aluminum-Magnesium-Silicon alloy. These conductors boast a superior strength-to-weight ratio compared to standard AAC, allowing for longer spans and reduced support structures in challenging terrains. Their improved sag characteristics minimize clearance issues, while excellent corrosion resistance extends service life in aggressive environments like marine or polluted zones. Electrically, AAAC offers lower power losses and better conductivity, optimizing energy efficiency in distribution networks. Manufactured to standards such as IEC 61089 and ASTM B399, they feature concentric stranding for mechanical stability and ease of installation with simpler fittings than ACSR. Versatile in size from small distribution lines to high-voltage transmission, AAAC supports applications on poles, towers, and substations. By reducing maintenance and enhancing reliability, these conductors provide a sustainable, cost-efficient alternative for modern power infrastructure, contributing to greener energy systems worldwide. Their lightweight design also facilitates easier handling during setup.

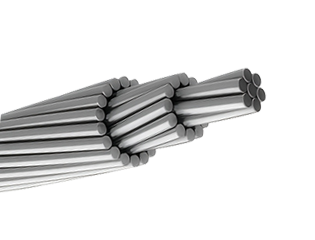

ALL ALUMINUM CONDUCTORS(AAC)

All Aluminum Conductors (AAC) are essential for overhead power transmission and distribution, constructed from concentrically stranded hard-drawn 1350 aluminum wires. Known for their superior electrical conductivity—up to 61.2% IACS—these conductors minimize energy losses, making them cost-effective for urban and rural grids. Lighter than steel-reinforced options, AAC simplifies installation and reduces structural demands on poles and towers. Their excellent corrosion resistance suits moderate environments, though they exhibit higher sag in long spans compared to alloys. Compliant with standards like ASTM B231 and IEC 60889, AAC is available in various sizes, from small distribution lines to higher voltage applications. The stranded design enhances flexibility and durability against wind and ice loads. Ideal for primary and secondary overhead lines, AAC supports efficient power delivery with minimal maintenance. By optimizing conductivity and weight, these conductors contribute to sustainable energy infrastructure, reducing operational costs and enhancing reliability in standard utility setups. Their recyclability aligns with eco-friendly practices in modern electrical networks.

ALUMINUM CONDUCTOR ALLOY REINFORCED(ACAR)

Aluminum Conductor Alloy Reinforced (ACAR) is a high-performance overhead conductor featuring concentrically stranded 1350-H19 aluminum wires around a core of 6201 aluminum-magnesium-silicon alloy strands. This design optimizes the balance between electrical conductivity and mechanical strength, offering higher ampacity than equivalent AAAC and better strength-to-weight ratio than AAC. ACAR excels in applications requiring reduced sag and enhanced durability, with excellent corrosion resistance suitable for coastal or industrial settings. Compliant with ASTM B524, B231, and B398 standards, it supports various stranding configurations for flexibility in line design. The alloy reinforcement provides superior tensile strength (up to 30% more than pure aluminum), minimizing support structures and installation costs. Ideal for primary and secondary distribution, ACAR reduces energy losses while maintaining reliability under heavy loads or extreme weather. Its lightweight nature facilitates easier handling, and full aluminum construction ensures recyclability, aligning with sustainable power infrastructure goals. ACAR is a versatile choice for modern grids seeking efficiency and longevity.

ALUMINUM CONDUCTOR STEEL REINFORCED(ACSR)

Aluminum Conductor Steel Reinforced (ACSR) is a widely used overhead conductor consisting of concentrically stranded 1350-H19 aluminum wires surrounding a galvanized steel core. This design provides exceptional tensile strength from the steel while leveraging aluminum's high conductivity (up to 61% IACS) for efficient power transmission with minimal losses. ACSR excels in long-span applications, offering low sag and high ampacity, making it suitable for high-voltage lines where mechanical reliability is critical. Resistant to corrosion through galvanization, it withstands harsh weather, including ice and wind loads. Compliant with ASTM B232, B230, and B498 standards, ACSR comes in various configurations like single or multiple steel strands for customized strength-to-weight ratios. It's cost-effective, reducing the need for additional supports and simplifying installation on towers or poles. With proven durability, ACSR enhances grid stability and longevity, supporting global utility networks. Its recyclability promotes environmental sustainability, making it a staple for modern electrical infrastructure in rural and urban settings.

ALUMINUM CONDUCTOR ALUMINUM CLAD STEEL REINFORCED(ACSR/AW)

Aluminum Conductor Aluminum-Clad Steel Reinforced (ACSR/AW) offers enhanced protection for overhead lines, with outer 1350 aluminum strands encircling an aluminum-clad high-strength steel core. The cladding significantly boosts corrosion resistance over traditional ACSR, ideal for marine, acidic, or high-humidity settings. Steel reinforcement provides superior mechanical properties, enabling longer spans with reduced sag and higher load capacity. Electrical conductivity from aluminum layers ensures minimal transmission losses, supporting ampacities up to 20% higher in equivalents. Adhering to IEC 61089 and ASTM B549, ACSR/AW features versatile stranding options for optimized ratios. Its design facilitates easy installation and compatibility with existing hardware. Lightweight yet robust, it lowers infrastructure costs and maintenance needs. ACSR/AW promotes sustainability through better longevity and recyclability, reducing environmental impact. Widely adopted in global utilities, it delivers reliable performance in extreme conditions, from stormy coasts to industrial hubs, making it a smart choice for future-proofing power grids.

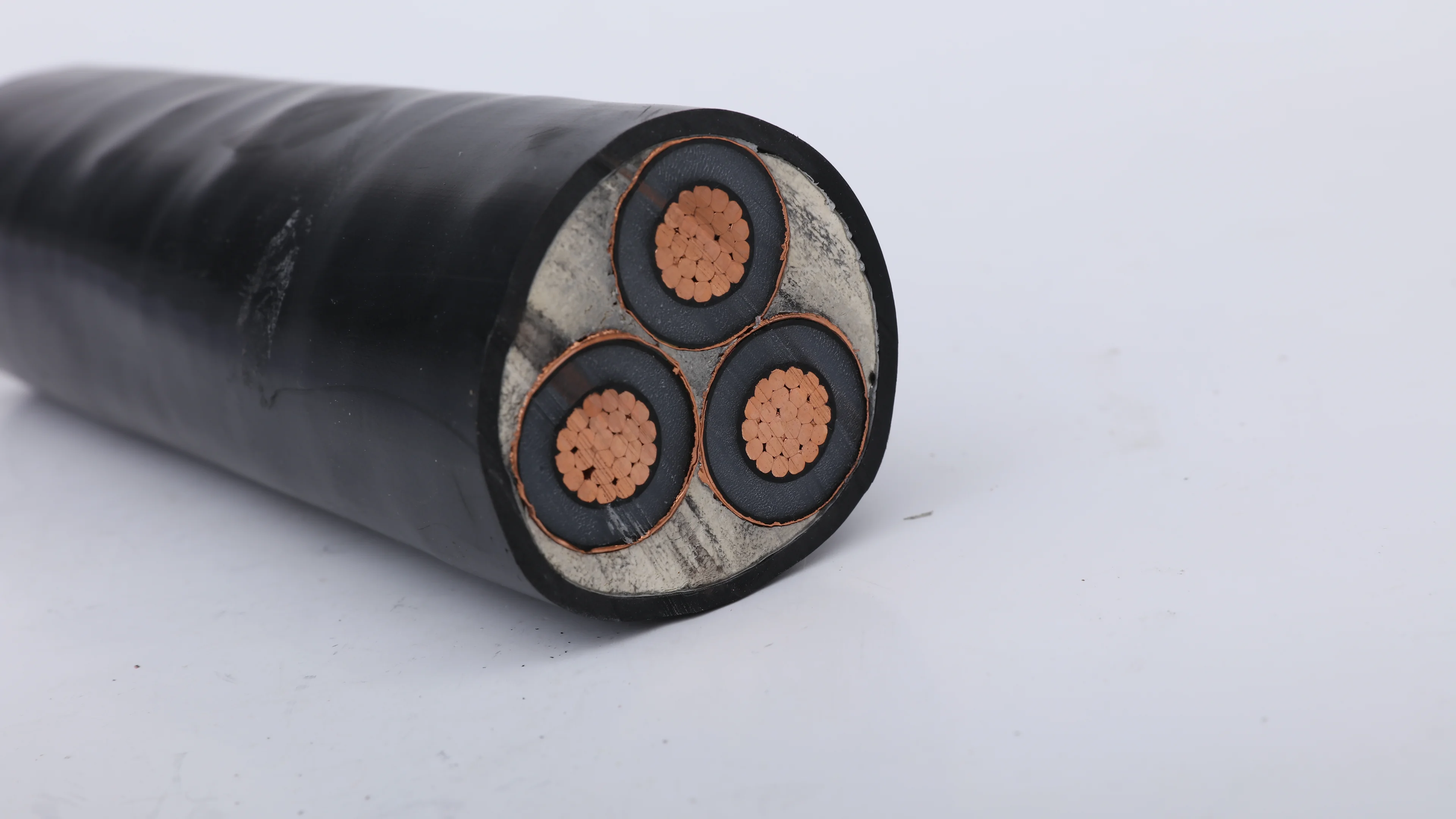

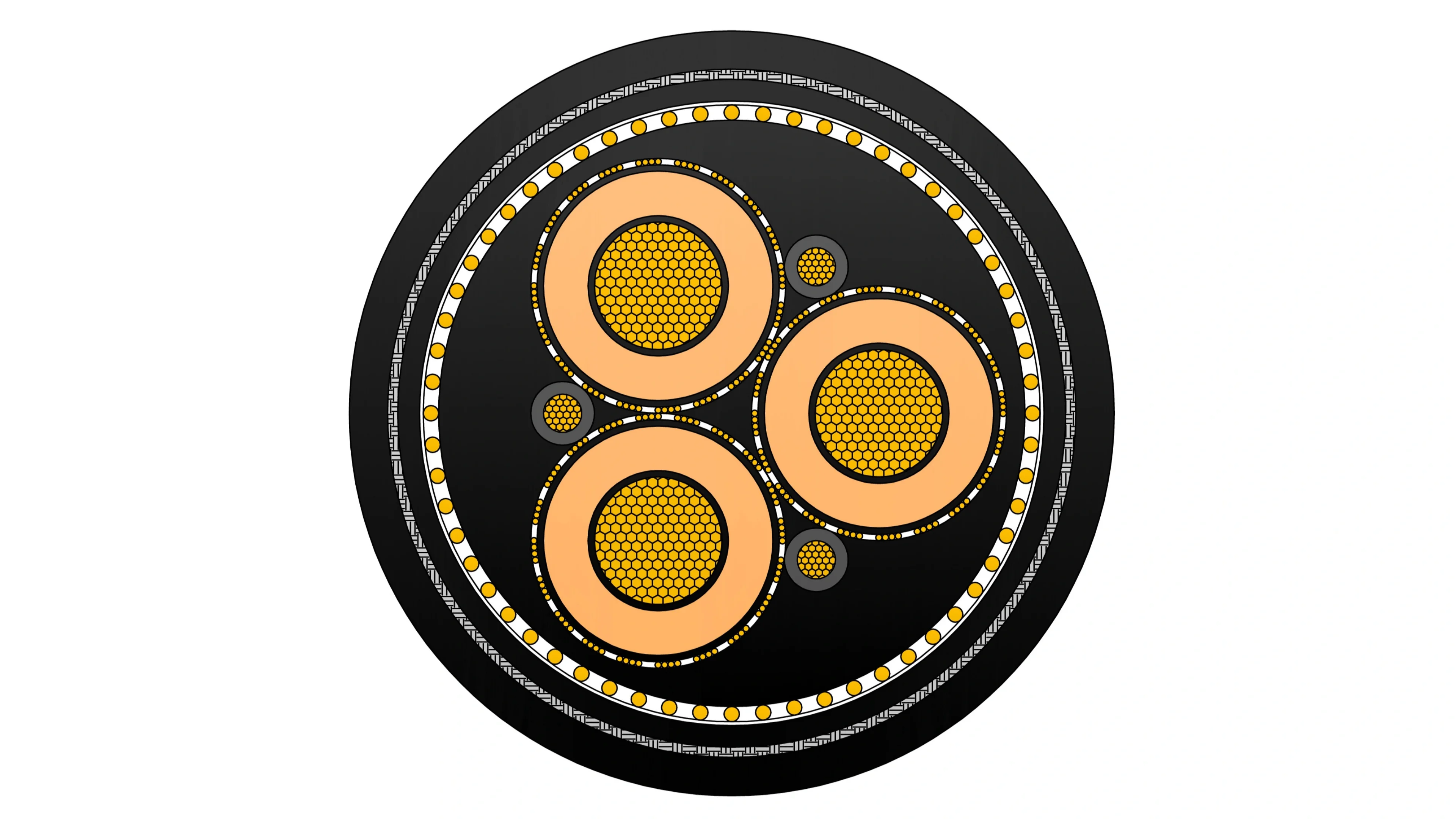

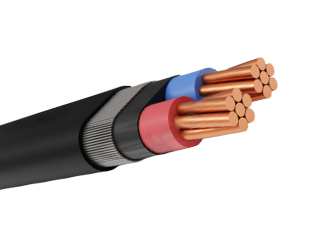

CONCENTRIC CABLE

NPC Electric Concentric Cable is designed with a central phase conductor surrounded by an evenly distributed concentric neutral conductor, providing a stable electrical return path and enhanced system safety. The concentric construction ensures uniform current distribution, reduces electromagnetic interference, and improves grounding reliability. High-purity copper or aluminum conductors are combined with durable insulation materials that offer excellent resistance to moisture, heat, and environmental stress. This cable structure is widely used in low-voltage power distribution, where mechanical protection and electrical stability are critical. The concentric neutral layer also enhances fault current handling and minimizes voltage drop during operation. With strong mechanical strength, long service life, and consistent electrical performance, concentric cables are suitable for underground installation and utility networks requiring dependable power delivery.

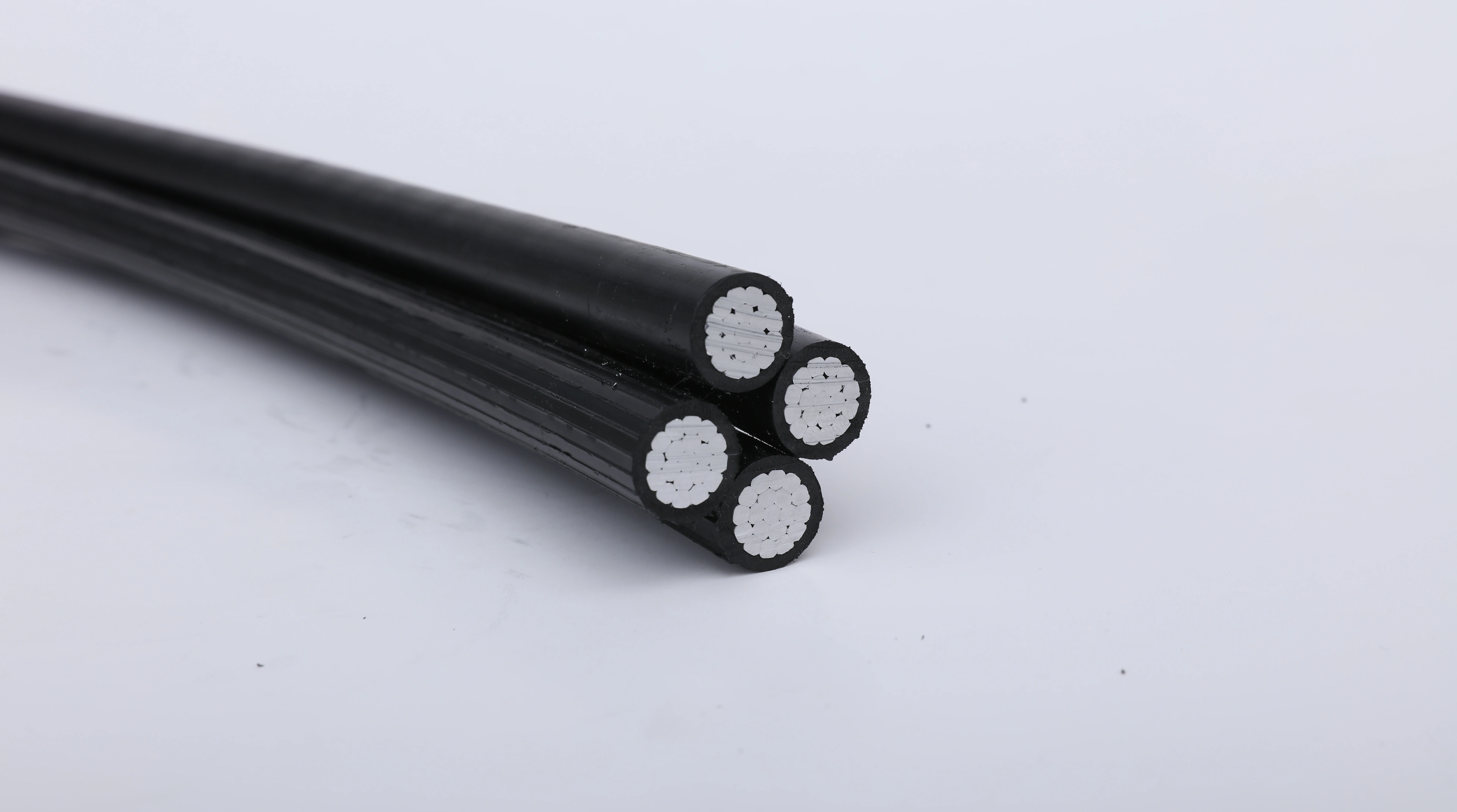

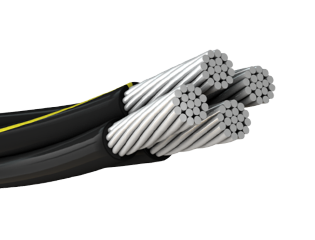

ABC CABLE NFC 33-209

Aerial Bundled Cable under NPC 33-209 standard is mainly used in the field of overhead power distribution. ABC Cable, manufactured in accordance with NFC 33-209 is designed for overhead low-voltage power distribution with enhanced mechanical strength and operational safety. The cable consists of insulated aluminum phase conductors twisted around a reinforced messenger conductor, forming a compact aerial bundle. This structure reduces the risk of short circuits caused by external contact and minimizes power outages in densely populated or environmentally challenging areas. The insulation material provides excellent resistance to UV radiation, weather exposure, and thermal aging, ensuring stable electrical performance over long service periods. Compliant with NFC 33-209 requirements, the cable delivers reliable current transmission, reduced line losses, and simplified installation compared with bare conductors. ABC Cable NFC 33-209 is widely used by utility companies for modern overhead distribution networks where safety, durability, and cost efficiency are critical.

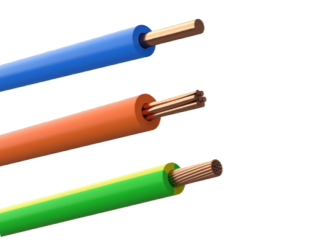

H05V-U H05V-R H05V-K

H05V-K cable is used for the internal wiring of electric motors and transformers as well as other electrical appliances and lighting applications. It can be used in and at electronic appliances for measuring, regulating and controlling. The cables are also ideal for laying in pipes, surface wiring and conduit installations. Specifications according to HD 516 apply for respective specific applications. H05V-U cable is intended for the installation to the inside of apparatus as well as for the protective laying to the lightings, in dry rooms, in production facilities, switch and distributor boards, in tubes, under and surface mounting of plasters. H05V-R is preferably for installation indoors, in cable ducts and in industrial plants or switching stations, under ground installation. Can be used in switchboards and distributor boards or where a thicker strand of multi-wire is required.Found in electronic and electrical equipment and switch gear cabinets designed for export to a European country and for MRO replacement of European made equipment wire.

TW AND THW

Electrical wire TW AND THW is used in new construction projects or rewiring tasks in 600-volt systems. It is from NPC Electric are designed for building wiring applications where dependable electrical performance and installation safety are required. These single-core copper conductors are insulated with high-quality thermoplastic materials, providing stable conductivity, good mechanical protection, and resistance to heat and moisture. TW wire is suitable for dry or damp locations with moderate temperature ratings, while TH wire offers higher heat resistance for applications requiring enhanced thermal performance. Manufactured under strict quality control, NPC Electric TW and TH Wires deliver uniform insulation thickness, consistent conductor structure, and long service life. Their reliable performance and ease of handling make them a trusted choice for residential, commercial, and light industrial electrical installations.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, NPC wires and cables exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

NPC wires and cables have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

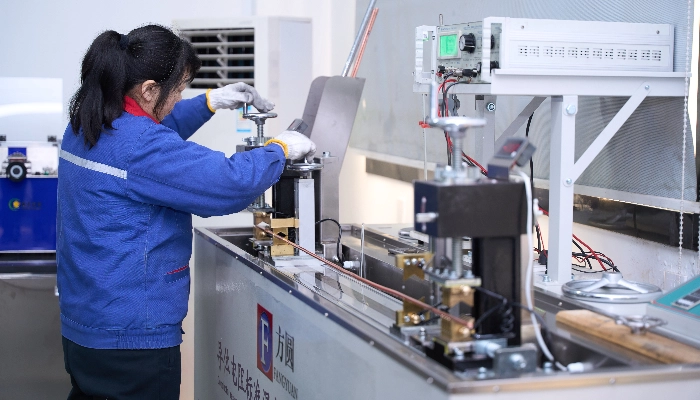

Wires & Cables Manufacturer

Wires & Cables Products

Wires & Cables Testing

Efficient Logistics & Timely Delivery

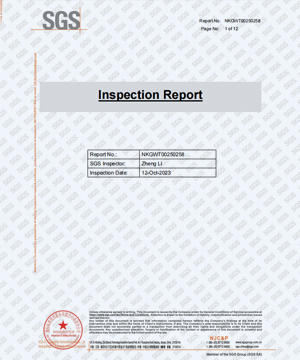

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

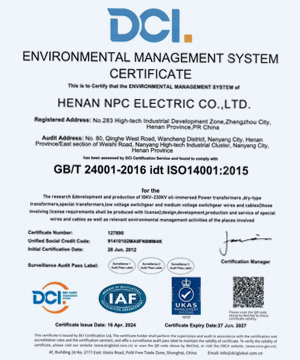

ISO Environmental Certificate

ISO Occupational Certificate

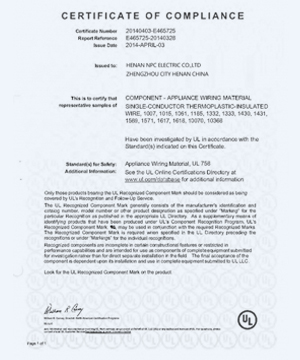

UL Laboratory Certificate

UL Product Certificate

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

Model:NPC AAAC Cable & Triplex Cable x 10km

Technical Advantages

FAQ From Customers

-

What is the difference between wires and cables?

A wire is a single conductor that carries electricity, while a cable is a group of two or more insulated electrical wires bundled together. Wires and cables are used to transmit electrical power or signals, but cables provide better protection and are often used where safety and durability are critical. -

How do I choose the right electrical cable for my project?

When selecting an electrical cable, consider the required voltage, current capacity, installation environment, and safety standards. For example, choose power cables for high-load transmission, solar cables for photovoltaic systems, or insulated electrical wires for indoor wiring. Always ensure the cable meets international standards such as IEC, UL, or ISO. -

What are the common types of wires and cables?

Common types include bare conductor cables for overhead transmission, power cables for industrial and residential electricity supply, solar cables for renewable energy systems, insulated cables for building wiring, grounding wires for safety, and submarine cables for undersea power transmission. -

Why is testing important for electrical wires and cables?

Testing ensures wires and cables meet safety, durability, and performance standards. High-quality electrical cables undergo conductivity, insulation, fire resistance, and mechanical strength tests to guarantee reliable operation. Properly tested electrical wires reduce energy loss, prevent short circuits, and increase system safety. -

Can NPC Electric provide customized wires and cables solutions?

Yes. With over 30 years of manufacturing experience, NPC Electric offers customized wires and cables, including electrical cables and electrical wires designed to specific voltage levels, insulation types, and installation conditions. Our engineering team supports custom solutions for power transmission, industrial automation, renewable energy, and infrastructure projects worldwide.