Wires and Cables

Wires and Cables

Type 245 Flexible Rubber Mining Cable

The Type 245 Flexible Rubber Mining Cable is an extra-heavy-duty flexible cable purpose-built for the most severe high-voltage underground mining environments. It features finely stranded tinned copper conductors (class 5) for exceptional flexibility and corrosion resistance, EPR (ethylene propylene rubber) insulation for outstanding dielectric strength, thermal stability (90°C continuous rating), and resistance to moisture/heat, an overall tinned copper braid screen providing superior EMI protection and grounding, and an extra-heavy-duty flame-retardant rubber outer sheath engineered to endure extreme abrasion, crushing, impact, cutting, tearing, oils, chemicals, and repeated high-tension reeling/drag. Compliant with AS/NZS 2802 and rigorous mining safety standards, it supports very high tensile loads, frequent flexing, tight bending radii, and reliable operation in wet, dusty, and hazardous mine conditions. The Type 245 is specifically suited for high-power trailing applications in coal and metalliferous mines, powering longwall shearers, continuous miners, face conveyors, shuttle cars, and other critical high-capacity mobile equipment, delivering maximum safety, durability, and uptime.

Type 260 Armoured Mining Cable with Pilot Core

The Type 260 Armoured Mining Cable with Pilot Core is a medium-voltage, rubber-insulated cable designed for heavy-duty mining applications requiring high mechanical strength and electrical reliability. It features flexible stranded tinned copper conductors, EPR insulation, and tinned copper braiding for excellent screening. The pliable galvanised steel wire armour (SWA) provides superior mechanical protection, making it suitable for harsh mining environments. The interstitial pilot core allows enhanced control and monitoring functions. With a PCP heavy-duty sheath, it offers flame retardancy, oil resistance, and durability. Compliant with AS/NZS 1802 and related standards, it is ideal for feeder cables, mining machinery power supply, and transportable substations. The Type 245 is ideal for high-power trailing in coal and metalliferous mines, powering longwall shearers, continuous miners, face conveyors, and critical equipment with enhanced safety via pilot core and armour.

Type 275 Flexible Overall Semi-conductive Rubber Screened Mining Cable

The Type 275 Flexible Overall Semi-conductive Rubber Screened Mining Cable is a 1.1kV, medium-voltage cable designed for coal mining and heavy-duty industrial applications. It features tinned annealed copper conductors, EPR insulation, and a semi-conductive thermosetting compound screen for enhanced electrical performance. The cable is reinforced with polyamide yarn braid and protected by a heavy-duty CSP sheath, offering oil resistance, flame retardancy, and mechanical durability. Its robust construction ensures reliable power delivery to shuttle cars, electric pumps, and other mining equipment. Compliant with AS/NZS 2802 and stringent mining standards, it supports very high tensile loads, frequent flexing, tight bending radii, and reliable operation in wet, dusty, and hazardous mine environments.

Type 409 Flexible Copper Screened Mining Cable With Central Pilot

The Type 409 Flexible Copper Screened Mining Cable with Central Pilot is a heavy-duty flexible cable engineered for reliable and safe underground mining operations. It features finely stranded tinned copper conductors (class 5) for excellent flexibility and corrosion resistance, EPR (ethylene propylene rubber) insulation for superior dielectric strength and 90°C continuous thermal rating, an overall tinned copper braid screen providing effective EMI protection and grounding, a central pilot core for earth continuity monitoring, safety interlocks, and fault detection, and an extra-heavy-duty flame-retardant rubber outer sheath resistant to oil, abrasion, tearing, crushing, impact, and chemicals. Compliant with AS/NZS 2802 and mining safety standards, it supports high tensile loads, frequent reeling/drag, tight bending radii, and reliable performance in wet, dusty, and hazardous mine conditions. The Type 409 is ideal for power supply to continuous miners, shuttle cars, longwall equipment, drills, and other mobile machinery in coal and metalliferous mines, ensuring enhanced safety through pilot core monitoring and maximum durability.

Type 450 Flexible Copper Screened Mining Cable With Two Earth And One Pilot Core

The Type 450 Flexible Copper Screened Mining Cable is a medium-voltage, heavy-duty mining cable designed for power supply in draglines, slow reeling, and industrial applications requiring two earth cores and one pilot core. It features tinned annealed copper conductors, EPR (XR-EP-90) insulation, and a tinned copper/polyamide braid screen for electrical shielding. The double-layer HD-PCP sheath provides extra heavy-duty protection, including oil resistance, flame retardancy, and chemical durability. Available in voltage ratings from 3.3kV to 33kV, the cable meets AS/NZS 2802 and related standards, ensuring high performance and reliability in harsh mining environments.

Type 455 Flexible Screened Mining Cable With Two Earth And One Pilot Core

The Type 455 Flexible Screened Mining Cable With Two Earth And One Pilot Core is an extra-heavy-duty flexible cable designed for the most severe underground mining operations requiring enhanced electrical safety. It features finely stranded tinned copper conductors (class 5) for exceptional flexibility and corrosion resistance, EPR insulation for high dielectric strength and 90°C continuous rating, tinned copper braid screen for effective EMI protection and grounding, two dedicated earth cores for redundant grounding and increased safety, one pilot core for earth continuity monitoring and machine interlock protection, and an extra-heavy-duty flame-retardant rubber outer sheath resistant to oil, abrasion, tearing, crushing, impact, and chemicals. Compliant with AS/NZS 2802 and mining safety standards, it supports very high tensile loads, frequent reeling/drag, tight bending radii, and reliable performance in wet, dusty, and hazardous conditions. The Type 455 is ideal for high-power trailing applications in coal and metalliferous mines, powering longwall shearers, continuous miners, face conveyors, shuttle cars, and critical mobile equipment with dual earth redundancy and pilot monitoring for maximum safety.2Y-high-voltage-power-cable.webp)

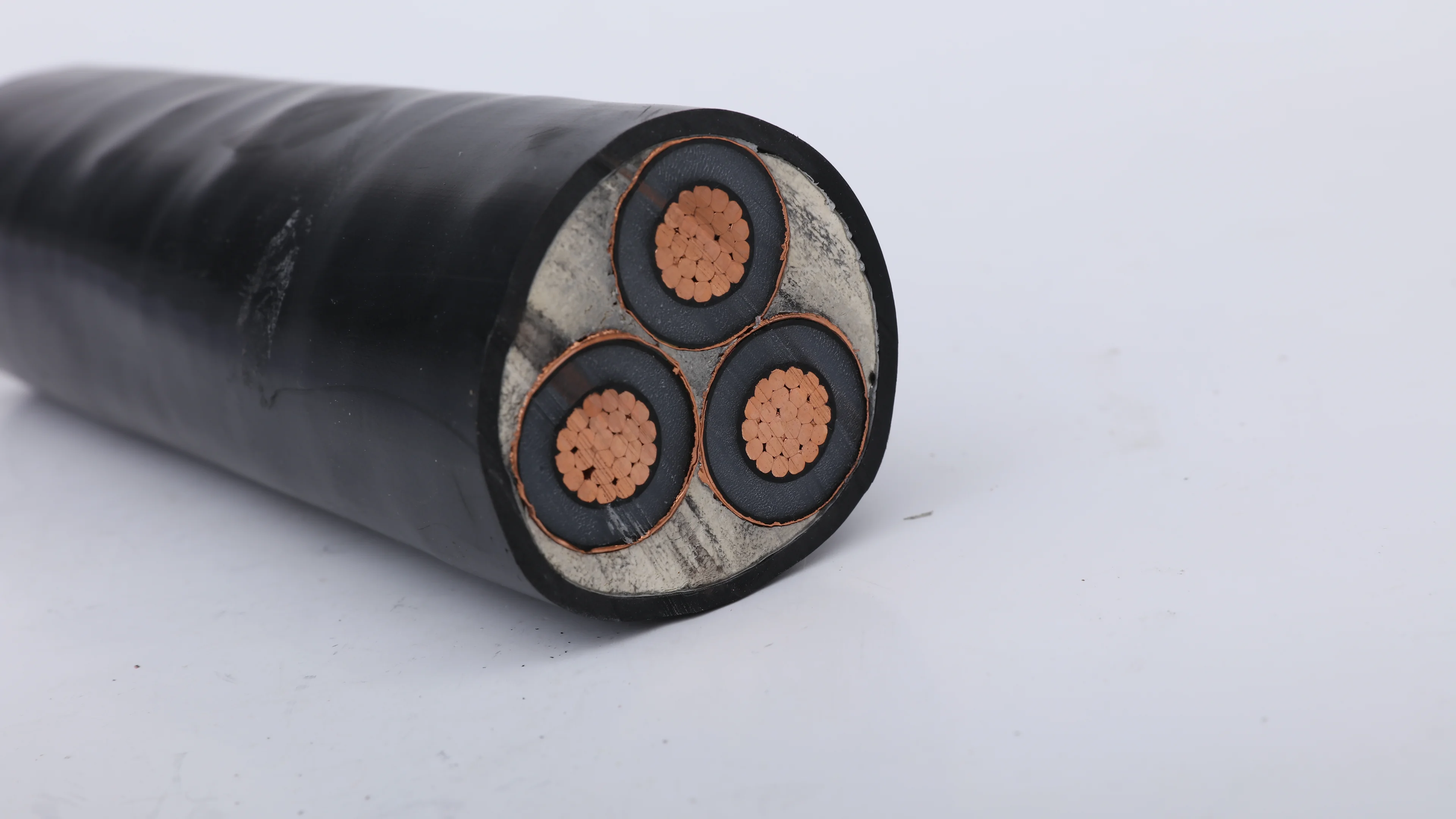

High Voltage / 2XS(F)2Y, A2XS(F)2Y 110kV Power Cable

The 2XS(F)2Y / A2XS(F)2Y 110kV High Voltage Power Cable is engineered for underground high-voltage transmission networks with a maximum operating voltage of 110kV (123kV highest). Built with Class 2 copper or aluminum Milliken conductors, extruded semi-conductive XLPE screens, and XLPE insulation, it ensures excellent electrical performance and long service life. Its copper wire screen with counter-helical copper tape offers enhanced shielding, while the water-swellable tapes provide longitudinal water-blocking. The HDPE outer sheath delivers high abrasion resistance and durability, making it ideal for installation in environments with existing mechanical protection. Manufactured to IEC 60840, HRN HD 632, and IEC/EN 60228 standards, this cable is well-suited for high-load and long-distance transmission applications.2Y-high-voltage-power-cable.webp)

High Voltage / 2XS(FL)2Y, A2XS(FL)2Y 110kV Power Cable

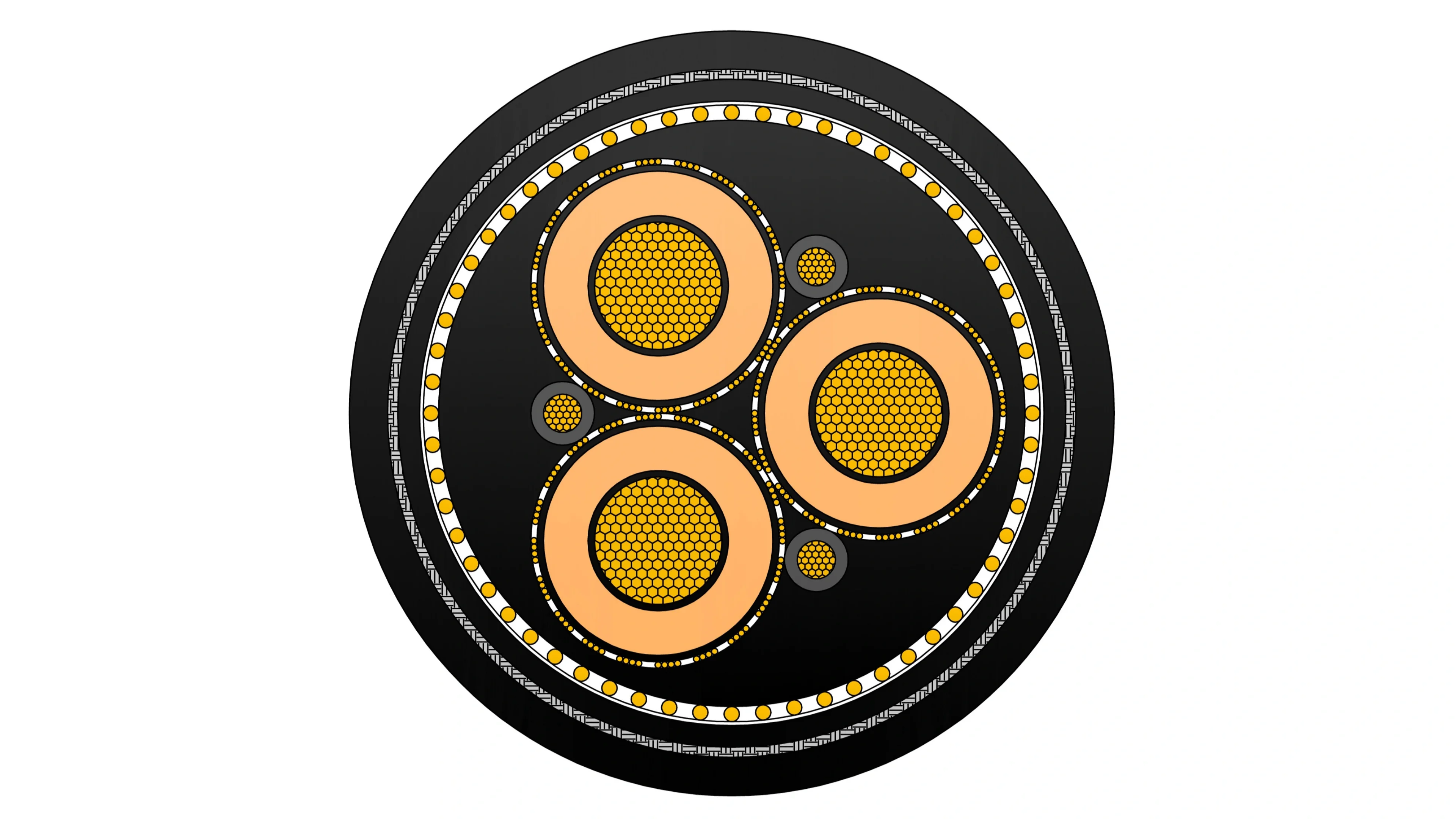

2XS(FL)2Y / A2XS(FL)2Y 110kV High Voltage Power Cable is a longitudinally watertight, XLPE-insulated cable designed for primary power distribution up to 110kV (123kV highest). It features a Class 2 copper or aluminium conductor, extruded semi-conductive XLPE screens, and XLPE insulation applied via a three-layer co-extrusion process for superior electrical performance. A laminated aluminium or copper moisture barrier with copolymer coating provides excellent water and gas resistance, while HDPE oversheath ensures high abrasion resistance and flexibility. The copper wire screen with counter-helical copper tape offers optimal shielding, and water swellable tapes ensure longitudinal water blocking. Manufactured to IEC 60840, HRN HD 632, and IEC/EN 60228 standards, this cable is ideal for underground installations requiring high reliability and moisture protection.2Y-high-voltage-power-cable.webp)

2XS(FL)2Y HDPE High Voltage 26/45 (52) kV Power Cable

2XS(FL)2Y HDPE High Voltage 26/45 (52) kV Power Cable is a high-performance XLPE-insulated cable designed for medium-to-high voltage transmission. It features a copper or aluminum conductor (optional watertightness – WTC), extruded semi-conductive conductor, and insulation screens, and water-swellable tapes for longitudinal water blocking. A longitudinally applied aluminium tape moisture barrier coated with PE copolymer provides excellent mechanical protection and resistance to moisture ingress. The HDPE oversheath offers superior abrasion resistance, chemical resistance, and durability, making it suitable for underground, underwater, outdoor, indoor, and duct installations in power stations, industrial plants, and distribution networks. Compliant with IEC 60840 standards, it ensures reliable performance in demanding environments.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, NPC wires and cables exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

NPC wires and cables have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

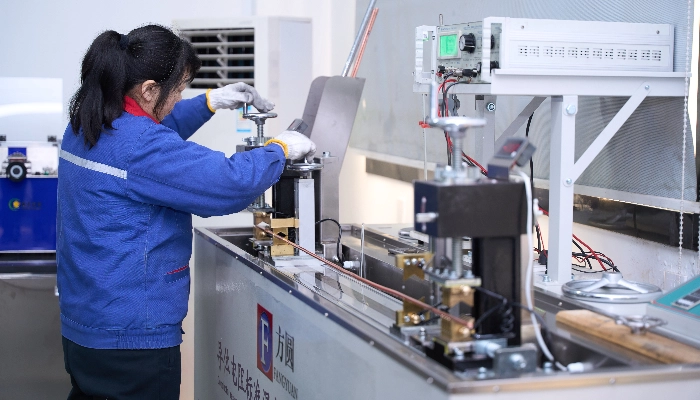

Wires & Cables Manufacturer

Wires & Cables Products

Wires & Cables Testing

Efficient Logistics & Timely Delivery

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

ISO Environmental Certificate

ISO Occupational Certificate

UL Laboratory Certificate

UL Product Certificate

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

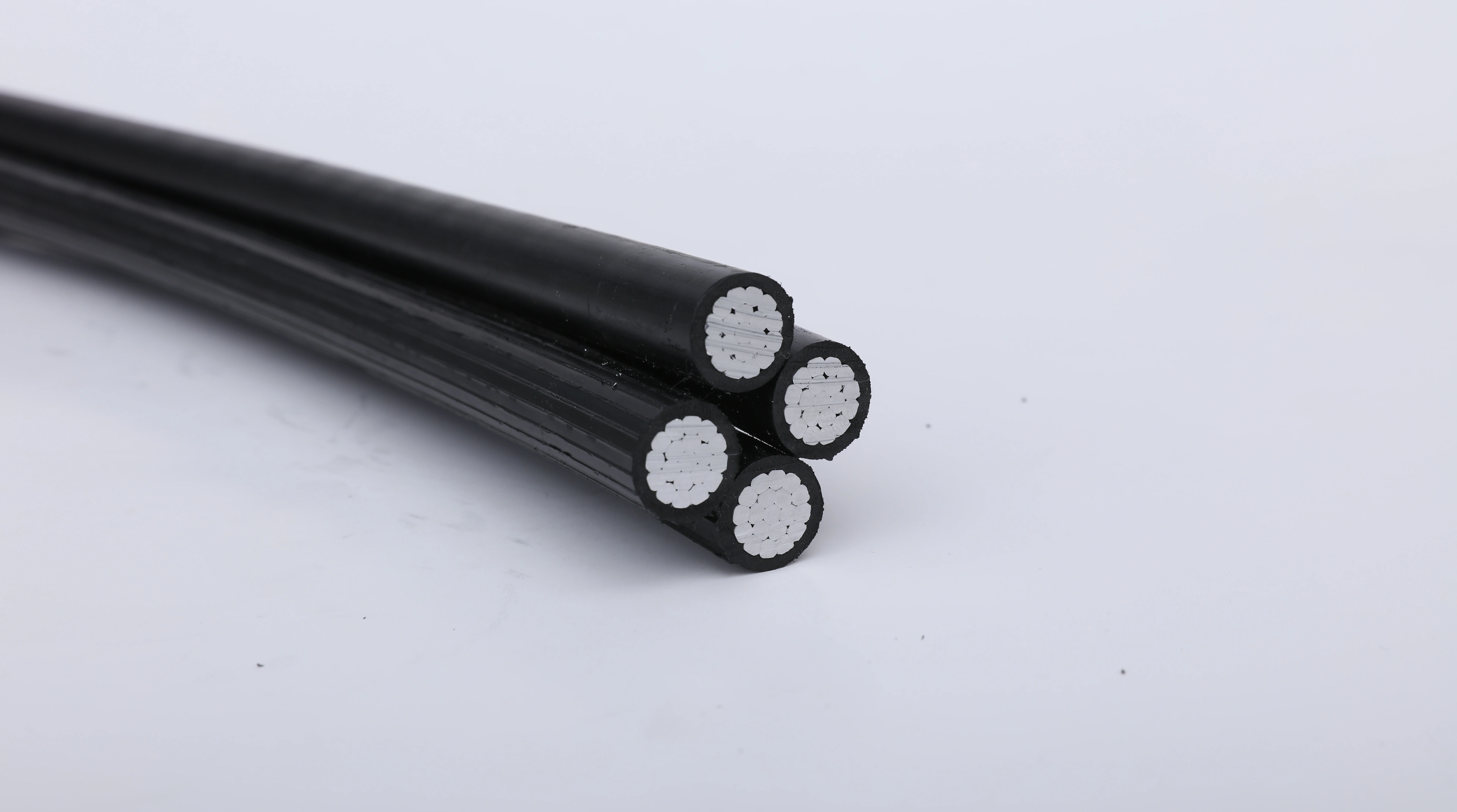

Model:NPC AAAC Cable & Triplex Cable x 10km

Technical Advantages

FAQ From Customers

-

What is the difference between wires and cables?

A wire is a single conductor that carries electricity, while a cable is a group of two or more insulated electrical wires bundled together. Wires and cables are used to transmit electrical power or signals, but cables provide better protection and are often used where safety and durability are critical. -

How do I choose the right electrical cable for my project?

When selecting an electrical cable, consider the required voltage, current capacity, installation environment, and safety standards. For example, choose power cables for high-load transmission, solar cables for photovoltaic systems, or insulated electrical wires for indoor wiring. Always ensure the cable meets international standards such as IEC, UL, or ISO. -

What are the common types of wires and cables?

Common types include bare conductor cables for overhead transmission, power cables for industrial and residential electricity supply, solar cables for renewable energy systems, insulated cables for building wiring, grounding wires for safety, and submarine cables for undersea power transmission. -

Why is testing important for electrical wires and cables?

Testing ensures wires and cables meet safety, durability, and performance standards. High-quality electrical cables undergo conductivity, insulation, fire resistance, and mechanical strength tests to guarantee reliable operation. Properly tested electrical wires reduce energy loss, prevent short circuits, and increase system safety. -

Can NPC Electric provide customized wires and cables solutions?

Yes. With over 30 years of manufacturing experience, NPC Electric offers customized wires and cables, including electrical cables and electrical wires designed to specific voltage levels, insulation types, and installation conditions. Our engineering team supports custom solutions for power transmission, industrial automation, renewable energy, and infrastructure projects worldwide.