Wires and Cables

Mining Cable

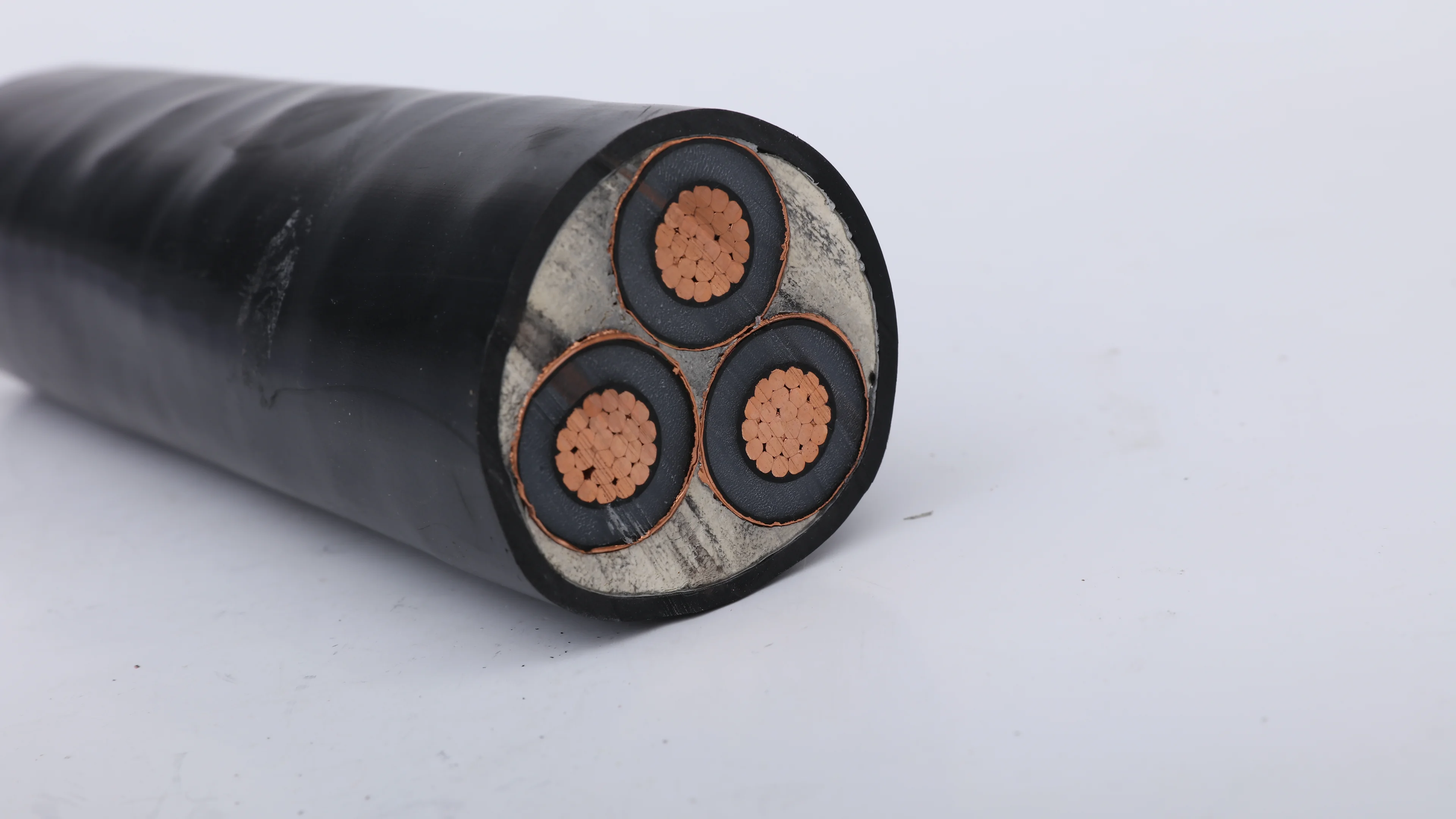

Type 209 Flexible Copper Screened Mining Cable

The Type 209 Flexible Copper Screened Mining Cable is a medium-voltage rubber-insulated cable designed for heavy-duty mining operations. It features tinned annealed copper conductors, EPR insulation, and a flexible copper wire/polyamide braid screen for superior electrical shielding. The extra heavy-duty PCP sheath provides oil resistance, flame retardancy, and high mechanical strength, making it ideal for trailing, feeder, and drilling applications in mining. Available in 1.1kV, 3.3kV, 6.6kV, and 11kV ratings, this cable complies with AS/NZS 2802 and ensures long service life under extreme conditions.

Type 210 Flexible Rubber Mining Cable

The Type 210 Flexible Rubber Mining Cable is a 1.1kV medium-voltage cable engineered for mining handheld drills and boring machines. It features flexible stranded tinned annealed copper conductors, EPR insulation, and a composite copper/polyester screen for improved electrical shielding. The heavy-duty PCP sheath offers oil resistance, abrasion protection, and flame retardancy, ensuring durability in harsh underground conditions. Compliant with AS/NZS 2802 and related standards, this cable delivers long-lasting performance in demanding environments requiring high flexibility and mechanical strength.

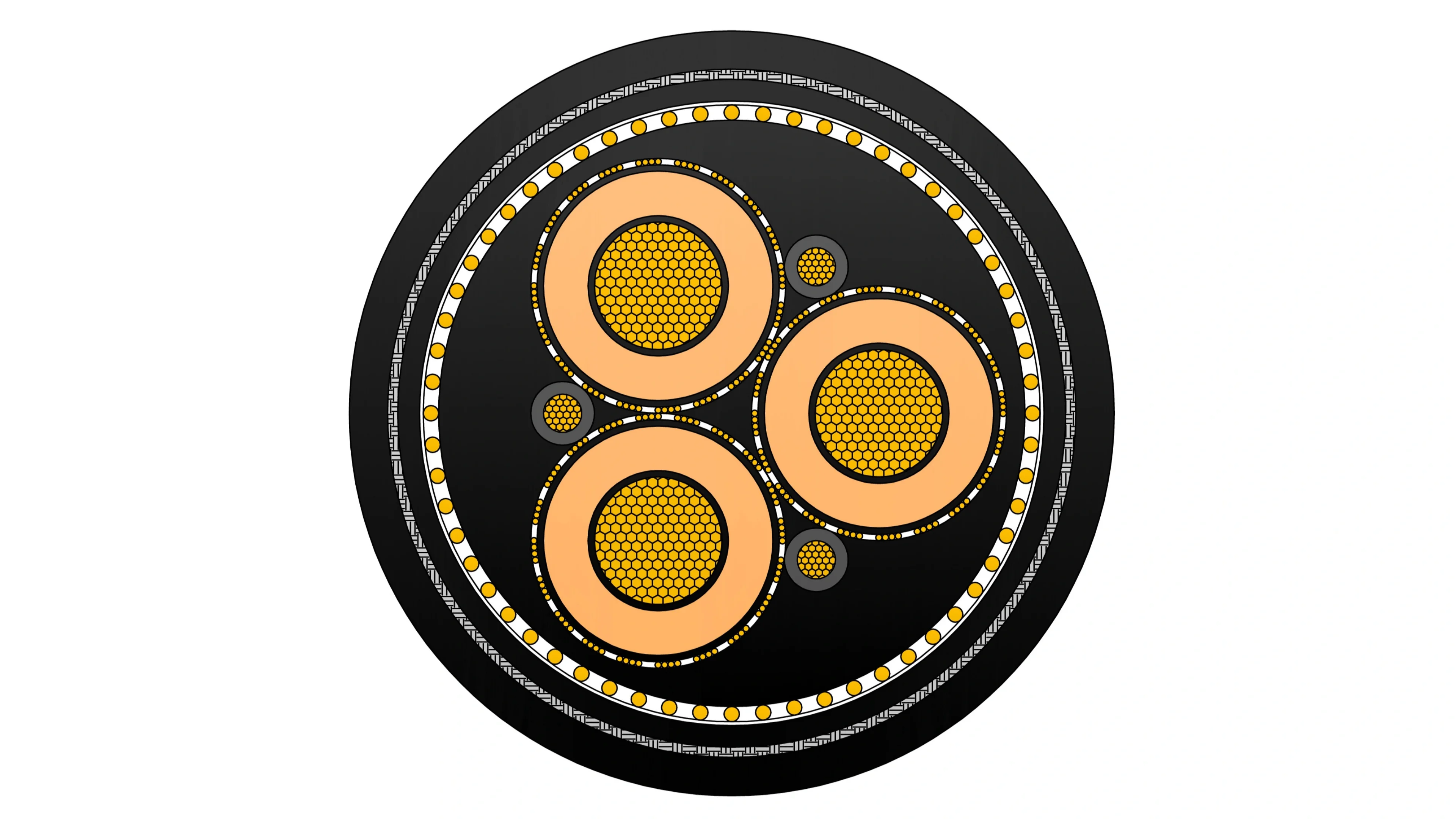

Type 440 Flexible Copper Screened Mining Cable With Three Pilot Core Interstitial

The Type 440 Flexible Copper Screened Mining Cable is a medium-voltage mining cable designed for heavy-duty applications in draglines, shovels, and large drills.It features tinned annealed copper conductors, EPR insulation, and a flexible copper wire screen for superior electrical shielding. Its three pilot cores allow for enhanced monitoring and control in mining operations. The extra heavy-duty PCP sheath provides oil resistance, abrasion protection, and flame retardancy, making it suitable for harsh mining environments. Compliant with AS/NZS 2802 and related standards, this cable ensures long service life and high mechanical performance in demanding conditions. Its flexible construction allows for repeated bending and movement under harsh operating conditions. The outer sheath provides excellent resistance to abrasion, oil, moisture, impact, and environmental aging. Manufactured under strict quality control procedures, the Type 440 mining cable undergoes comprehensive raw material testing, process inspection, and finished product testing to ensure compliance with mining regulations and long-term performance.

Type 441 Flexible Semi-Conductive Screened Mining Cable

The Type 441 Flexible Semi-Conductive Screened Mining Cable is a medium-voltage rubber-insulated cable engineered for harsh mining applications. It features tinned annealed copper conductors, EPR insulation, and semi-conductive screening for optimal electrical performance. Designed with three earth/protective cores and one pilot core, it is ideal for powering draglines, shovels, and drills, as well as for trailing and reeling uses in mining and industrial environments. Its HD-CSP extra heavy-duty outer sheath delivers oil resistance, flame retardancy, and high mechanical durability, ensuring long service life in demanding operational conditions. Compliant with AS/NZS 2802 and related standards, this cable provides reliable performance under extreme stress. The flexible construction of the Type 241 mining cable allows repeated bending and movement without compromising electrical performance. Manufactured under a strict quality management system, the cable undergoes comprehensive raw material testing, process inspection, and finished product testing to ensure compliance with mining standards and long-term operational reliability.

Type 240 Flexible Copper Screened Mining Cable With Three Pilots

The Type 240 Flexible Copper Screened Mining Cable with Three Pilots is a medium-voltage, rubber-insulated cable designed for mining machinery feeder applications and longwall supply. It features tinned annealed copper conductors, EPR insulation, and a tinned copper/polyamide braid screen for superior electrical and mechanical performance. The three interstitial pilot cores provide additional monitoring or control functions, making it suitable for complex mining and industrial systems. With its HD-PCP extra heavy-duty outer sheath, the cable offers oil resistance, flame retardancy, and high durability for harsh environments. Compliant with AS/NZS 2802 and related standards, it ensures reliable operation under extreme mechanical and electrical stress. Constructed with high-conductivity copper conductors, durable insulation, and a robust outer sheath, the cable offers excellent resistance to abrasion, vibration, oil, moisture, and harsh mining conditions. Its flexible design supports continuous movement and reduces installation stress.

Type 241 Flexible Rubber Screened Mining Cable

The Type 241 Flexible Rubber Screened Mining Cable is a medium-voltage, rubber-insulated cable engineered for underground coal mining and general mining applications. It features tinned annealed copper conductors, EPR insulation, and a semi-conductive thermosetting screen for excellent electrical performance. The cable’s three screened power cores and three earth cores are arranged with a central pilot core for enhanced safety and control. With an HD-85-PCP extra heavy-duty outer sheath, it delivers oil resistance, flame retardancy, and superior mechanical durability. Compliant with AS/NZS 1802 and related standards, it ensures reliable operation under harsh mining conditions. The Type 241 is specifically suited for high-power trailing applications in coal and metalliferous mines, powering longwall shearers, continuous miners, shuttle cars, loaders, and face equipment with maximum safety and uptime.

Type 245 Flexible Rubber Mining Cable

The Type 245 Flexible Rubber Mining Cable is an extra-heavy-duty flexible cable purpose-built for the most severe high-voltage underground mining environments. It features finely stranded tinned copper conductors (class 5) for exceptional flexibility and corrosion resistance, EPR (ethylene propylene rubber) insulation for outstanding dielectric strength, thermal stability (90°C continuous rating), and resistance to moisture/heat, an overall tinned copper braid screen providing superior EMI protection and grounding, and an extra-heavy-duty flame-retardant rubber outer sheath engineered to endure extreme abrasion, crushing, impact, cutting, tearing, oils, chemicals, and repeated high-tension reeling/drag. Compliant with AS/NZS 2802 and rigorous mining safety standards, it supports very high tensile loads, frequent flexing, tight bending radii, and reliable operation in wet, dusty, and hazardous mine conditions. The Type 245 is specifically suited for high-power trailing applications in coal and metalliferous mines, powering longwall shearers, continuous miners, face conveyors, shuttle cars, and other critical high-capacity mobile equipment, delivering maximum safety, durability, and uptime.

Type 260 Armoured Mining Cable with Pilot Core

The Type 260 Armoured Mining Cable with Pilot Core is a medium-voltage, rubber-insulated cable designed for heavy-duty mining applications requiring high mechanical strength and electrical reliability. It features flexible stranded tinned copper conductors, EPR insulation, and tinned copper braiding for excellent screening. The pliable galvanised steel wire armour (SWA) provides superior mechanical protection, making it suitable for harsh mining environments. The interstitial pilot core allows enhanced control and monitoring functions. With a PCP heavy-duty sheath, it offers flame retardancy, oil resistance, and durability. Compliant with AS/NZS 1802 and related standards, it is ideal for feeder cables, mining machinery power supply, and transportable substations. The Type 245 is ideal for high-power trailing in coal and metalliferous mines, powering longwall shearers, continuous miners, face conveyors, and critical equipment with enhanced safety via pilot core and armour.

Type 275 Flexible Overall Semi-conductive Rubber Screened Mining Cable

The Type 275 Flexible Overall Semi-conductive Rubber Screened Mining Cable is a 1.1kV, medium-voltage cable designed for coal mining and heavy-duty industrial applications. It features tinned annealed copper conductors, EPR insulation, and a semi-conductive thermosetting compound screen for enhanced electrical performance. The cable is reinforced with polyamide yarn braid and protected by a heavy-duty CSP sheath, offering oil resistance, flame retardancy, and mechanical durability. Its robust construction ensures reliable power delivery to shuttle cars, electric pumps, and other mining equipment. Compliant with AS/NZS 2802 and stringent mining standards, it supports very high tensile loads, frequent flexing, tight bending radii, and reliable operation in wet, dusty, and hazardous mine environments.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, NPC control & instrument cable exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

NPC mining cable have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

Mining Cable Manufacturer

Features of Mining Cables

Mining Cable Safety Standards

Testing & Quality Control

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

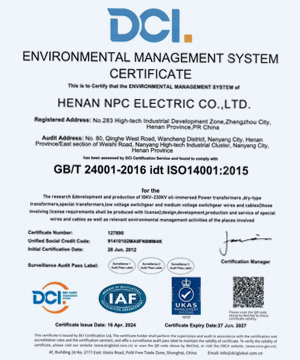

ISO Environmental Certificate

ISO Occupational Certificate

UL Laboratory Certificate

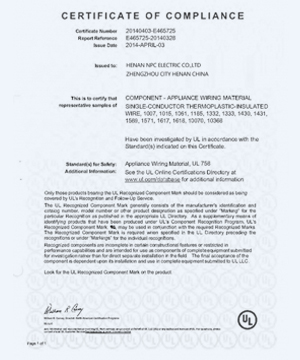

UL Product Certificate

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

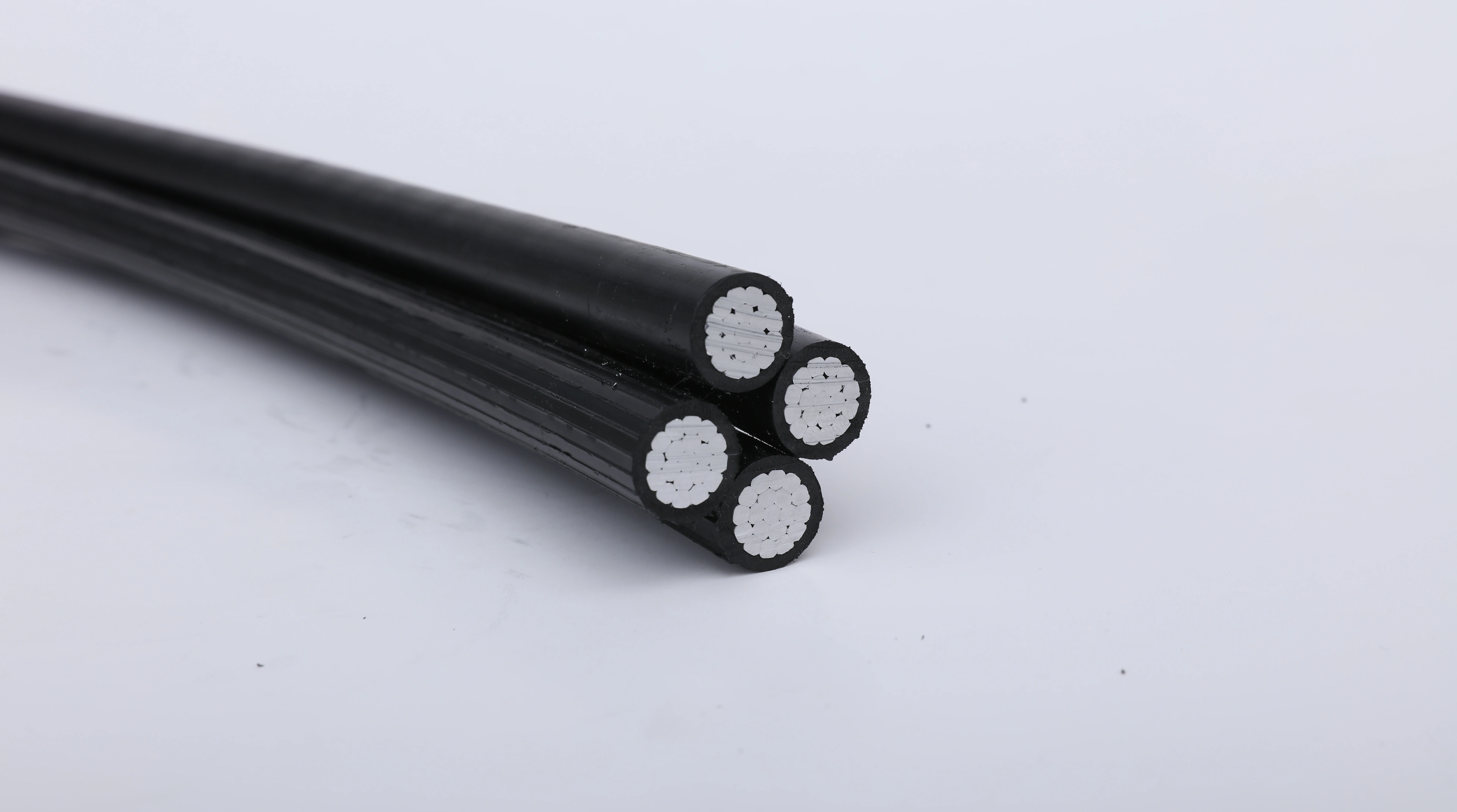

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

Model:NPC AAAC Cable & Triplex Cable x 10km

Technical Advantages

FAQ From Customers

-

What are the different types of mining cables?

There are several types of mining cables, each designed to meet specific electrical needs in mining environments:

1. Low Voltage Mining Cables: Used for power distribution within mining operations, typically up to 1 kV.

2. Medium Voltage Mining Cables: Designed for transmission of electricity at voltages between 1kV and 35kV to support large mining machinery and equipment.

3. High Voltage Mining Cables: Used in high voltage transmission for long-distance energy distribution, providing power to large-scale mining operations.

4. Flexible Mining Cables: These cables are designed to handle frequent movement and flexibility during mining operations, ensuring reliable performance in dynamic environments.

5. Instrumentation Cables: Used for signal transmission between control systems and equipment in the mining operation. -

What cable is used in mining?

Mining cables are specifically designed to handle the extreme conditions of underground and surface mining operations. These cables are typically made with high-quality copper or aluminum conductors, cross-linked polyethylene (XLPE) insulation, and robust sheathing materials such as PVC or thermoplastic rubbers to ensure they can withstand abrasion, chemical exposure, and mechanical stress. The most common types of cables used in mining include power cables, control cables, and instrumentation cables that ensure the safe operation of electrical systems, machinery, and communication devices in the mine. -

How are mining cables different from standard electrical cables?

Mining cables are built to meet the unique challenges of mining environments, including exposure to moisture, abrasion, extreme temperatures, and chemical exposure. Unlike standard electrical cables, mining cables have specialized insulation and protective sheaths that provide fire resistance, shock resistance, and mechanical protection. Additionally, mining cables often require certifications such as MSHA or IEC 60092 to ensure they meet safety standards for use in hazardous conditions. -

What materials are used in mining cables?

Mining cables are made from high-quality materials to ensure durability and safety in harsh environments. The conductors are usually made from copper or aluminum, offering excellent electrical conductivity. The insulation is typically made from cross-linked polyethylene (XLPE), which provides high thermal stability, electrical strength, and chemical resistance. The sheath is made from durable materials like PVC or PE, which protect the cable from abrasion, UV radiation, and moisture, ensuring that it can withstand extreme mining conditions. -

Why is flexibility important in mining cables?

Flexibility is crucial in mining cables because these cables often need to be installed in dynamic environments where they must bend or move as mining equipment and machinery are repositioned. Flexible mining cables are specifically designed to handle constant movement and maintain reliable performance in confined spaces or areas with high mechanical stress. These cables are ideal for use in drilling operations, mobile mining equipment, and areas where the cable may be subjected to frequent shifts in position.