1000kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards ANSI/IEEE, CSA/CAN, DOE

- Application BESS, Data center, Industry, Renewable energy

- Power Rating 1000kVA

- Certificate UL, cUL, CSA, SGS

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 1000 kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 650 kg |

| Total Weight | 3235 kg |

| Outline Dimensions(L×W×H)in. | 1854×1549×1651(mm) |

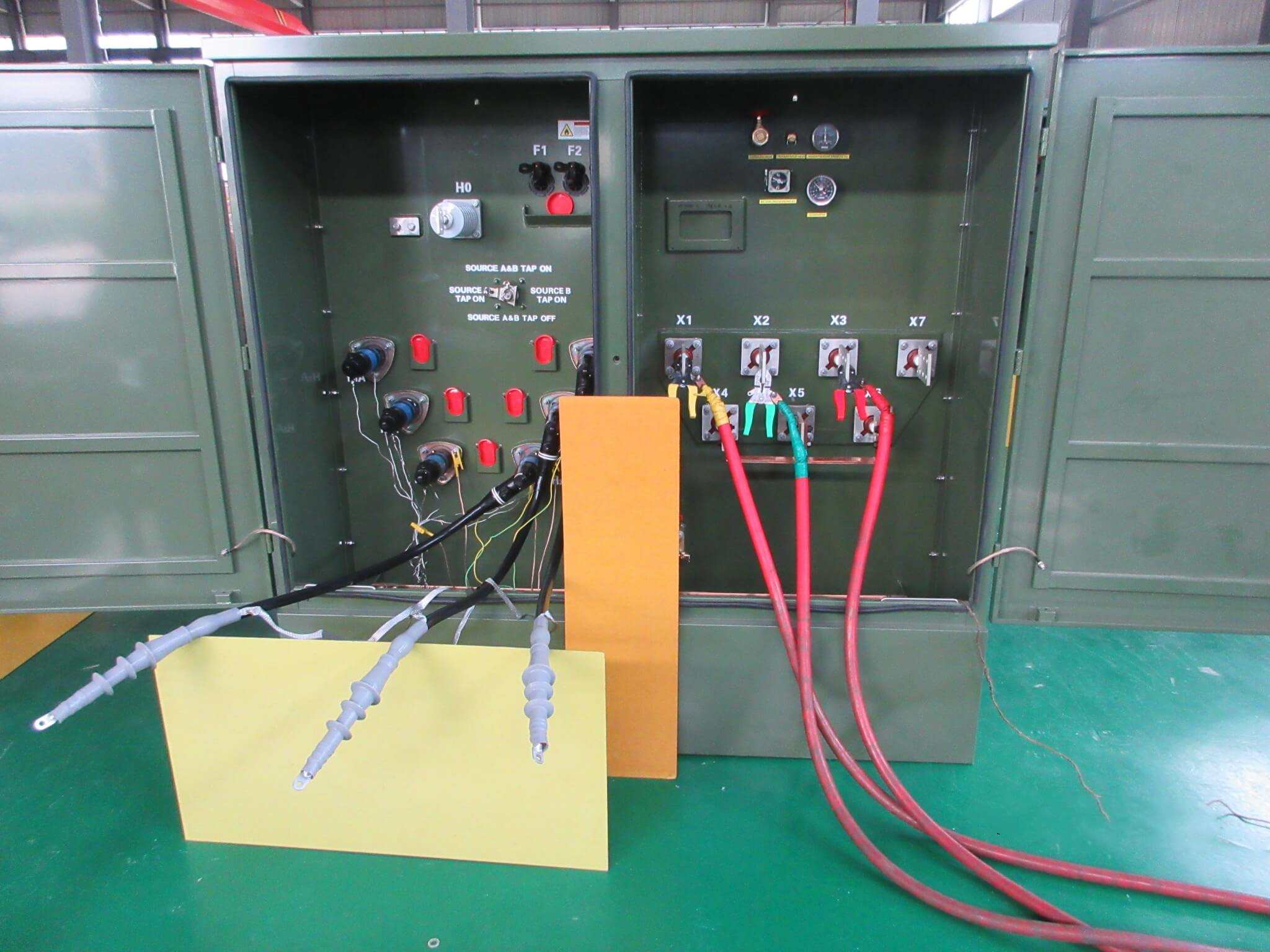

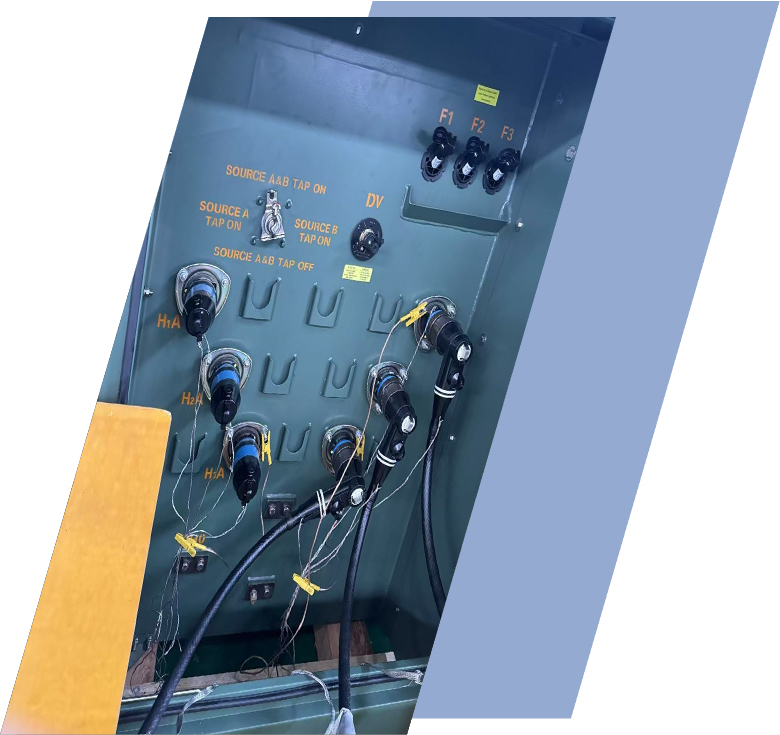

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

The optional specifications of 1000kVA three-phase ground transformers usually include multiple aspects to meet different application requirements.

Common options include different rated voltages (such as the voltage levels of the high-voltage and low-voltage sides), cooling methods (such as oil-immersed or dry-type transformers), insulation levels (such as Class A or Class B), and wiring methods (star or triangle connection).

In addition, you can also choose casing materials that are waterproof, dustproof, and corrosion-resistant to meet the requirements of use in harsh environments.

These optional specifications can be customized according to specific needs to ensure the stable operation and safety of the transformer.

With these flexible options, we ensure that our transformers can be customized for specific applications, environments, and safety standards, offering long-term reliability and performance.

Packing and Shipping

Packing materials: Transformers are usually packaged in sturdy wooden boxes or steel frames, and the outer layer is covered with waterproof and moisture-proof materials such as plastic film or tarpaulin to prevent moisture and humidity from invading. The lining can be made of foam, wood or other impact-resistant materials to reduce vibration and impact during transportation.

Marking and labeling: The packaging should clearly indicate the model, specification, weight, transportation requirements (such as "handle with care" or "waterproof") of the transformer, and the transportation direction mark to avoid errors when handling during transportation.

Fixation and support: During transportation, the transformer needs to be fixed on the transportation equipment to avoid damage to the equipment due to bumps, vibrations or tilting. Generally, steel straps or other fixing devices are used to ensure that it is firmly fixed in the pallet or container.

Transportation method: It is usually transported by road, rail or sea. The transformer should be properly packaged and reinforced according to the characteristics of the transportation method to ensure that it will not shift or be damaged during long-term transportation. When transported by sea, additional anti-corrosion measures may be required.

Environmental control: Avoid high temperatures, low temperatures, strong sunlight exposure or extreme weather conditions during transportation. Special attention should be paid to prevent moisture, dust or other contaminants from entering the transformer during transportation.

By following these basic packaging and transportation standards, you can ensure that the 1000kVA three-phase ground transformer is still in good operating condition when it arrives at its final destination and can be put into use smoothly.

Manufacturer Test

Progress test

NPC Electric manufacture pad mounted transformer have the strict quality control. The progress test of 1000kVA three-phase ground transformer usually includes a series of inspection and verification steps to ensure that the transformer meets the design standards and performance requirements during production and installation. Common progress test items are high voltage withstand test, load test and short circuit test. These progress tests help ensure the quality and reliability of the transformer and meet all safety and performance standards before delivery. Electrical progress tests encompass winding resistance at reference temperature, turns ratio confirmation across taps, no-load excitation current and preliminary loss measurements to identify core/winding defects promptly. Impedance and early load loss assessments validate design compliance. Results receive serialized traceable records, facilitating immediate corrections before advancement, ensuring full adherence to IEEE, ANSI, DOE, and client specifications throughout manufacturing for exceptional efficiency, longevity, and field reliability.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The Factory Acceptance Test (FAT) of 1000kVA three-phase ground transformer is a key link to ensure that the transformer meets the design specifications and quality standards before leaving the factory. The purpose of the factory acceptance test is to ensure that the transformer meets its design, function and quality requirements through comprehensive verification and inspection before delivery to the customer, thereby ensuring reliability and safety in actual use. Dielectric withstand includes applied potential and induced voltage tests at elevated levels without breakdown or partial discharge. Impedance voltage and load loss measurements under short-circuit conditions align with guaranteed values. Oil breakdown voltage, moisture, and acidity tests apply to filled units. Functional demonstrations verify fuse performance, pressure relief activation, gauge calibration, valve operation, and bushing integrity. Optional assessments like sound level evaluation, temperature rise simulation, or impulse testing occur per specification. Compiled results in certified reports, available for client/third-party witnessing, affirm conformity to IEEE C57.12.34, C57.12.00, guaranteeing superior in-service dependability and performance.

Routine Test - On load Loss Test

Voltage source and current source (usually rated voltage, or adjusted according to the test standard, such as 10 KV, 20 KV, 35 KV, etc.)

Temperature and humidity meter (used to record ambient temperature and humidity for correction of test data)

The test environment should be dry and rainless, with a relative humidity of less than 75% and a recommended temperature range of 20–30°C.

Connect the test equipment to the appropriate terminals of the device under test and ensure that all wiring is correct and the device is well grounded.

Apply Test Voltage:

Apply the specified test voltage at the rated frequency and adjust the low voltage side to maintain the rated current (or specified current).

On-Load Loss Power

Input Power and Output Power

Current

Voltage

Temperature (temperature rise or winding temperature)

Ambient temperature and humidity during the test

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.