450kVA Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed distribution transformer

- BIL 11/33kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application schools and hospitals, new energy grid, data centers

- Power Rating 450kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 450kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 950 kg | |

| Total Weight | 5200 kg | |

| Outline Dimensions(L×W×H)in. | 2750 × 1850 × 2550(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

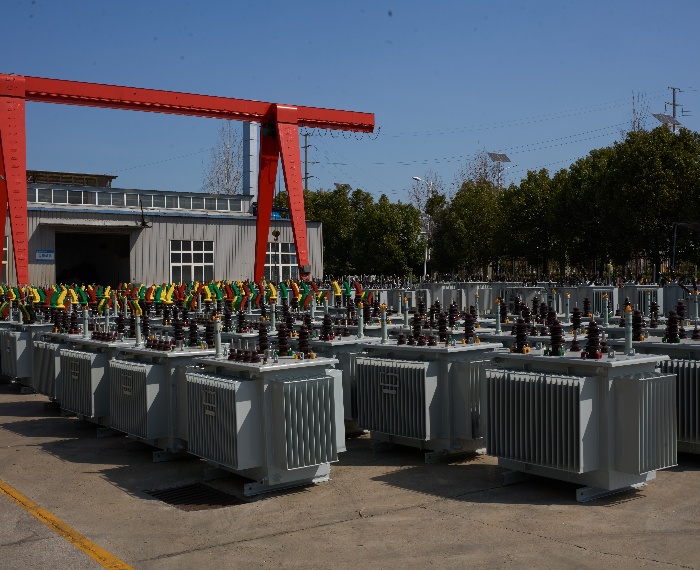

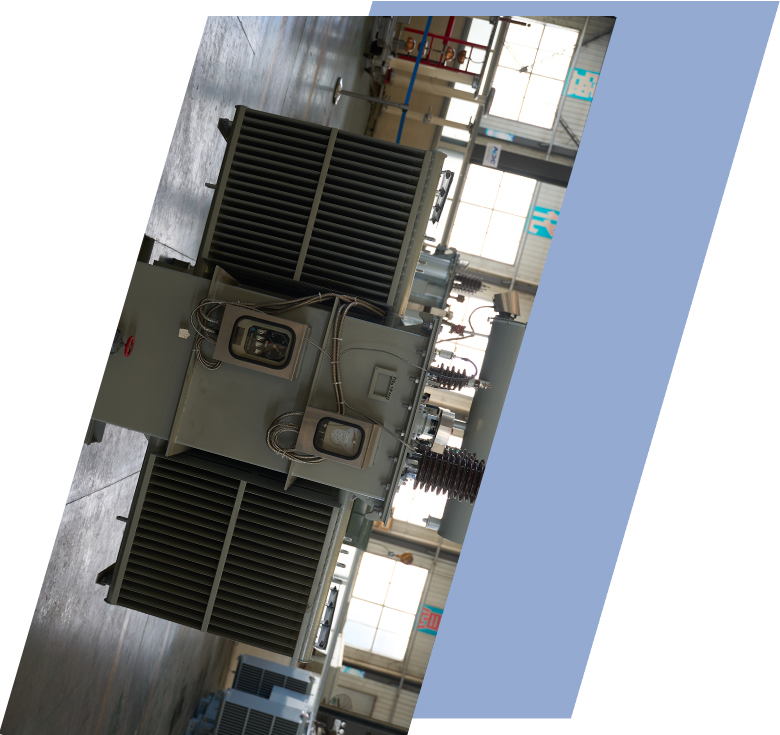

Packing and Shipping

Detached components receive individual safeguarding: radiators are padded and crated with anti-vibration materials, bushings in shock-resistant boxes, and control accessories sealed against dust/humidity with desiccants. The main tank secures to robust wooden ISPM-15 compliant crates or steel skids featuring custom blocking, lateral braces, and shock-absorbing elements capable of withstanding typical transport forces (up to 4-5g). Packaging includes multi-layer weatherproof barriers, volatile corrosion inhibitors, humidity/temperature indicators, and shock/tilt loggers for handling accountability throughout transit.

Ocean freight, the most common for export, utilizes flat-rack or open-top containers with IMO-standard lashing, salt-resistant wraps, and protective sheeting; road/rail segments employ low-bed trailers with balanced load distribution and marked crane lift points. Comprehensive export paperwork bundles commercial invoices, packing lists, certificates of origin/conformity, routine test reports, dimensional/lifting diagrams, oil SDS, installation manuals, and HS code declarations (8504.21 for distribution transformers ≤650kVA).

We coordinate complete logistics chains from factory departure to final destination, providing FOB/CIF terms, customs support, insurance options, and value-added services such as third-party inspections, professional unloading supervision, oil processing/filtering on arrival, erection guidance, and commissioning assistance. This thorough process safeguards against damage, ensures regulatory compliance, preserves performance characteristics, and delivers reliable, on-time arrival for customers worldwide in distribution, commercial, and light industrial sectors.

Manufacturer Test

Progress Test

Progress testing for 450kVA oil immersed transformer starts with silicon steel sheet inspection for thickness uniformity insulation coating magnetic permeability and burr-free edges via Epstein frame to minimize core losses then core stacking verifies precise mitered joints clamping torque uniformity and vibration suppression features. Winding process progress monitors conductor material purity enamel insulation application automated tension control turn precision and inter-layer dielectric strength checks post-winding. Core-coil assembly progress confirms adequate radial/axial clearances barrier placement end insulation compression and short-circuit force resistant structures. Tank production progress evaluates weld seam continuity hydrostatic pressure testing surface blasting multi-layer paint thickness and corrosion protection adherence pre-assembly progress checks bushing radiator valve alignment accessory installation and preliminary vacuum/pressure integrity tests to identify early issues ensuring smooth transition to detailed qualification stages.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory Acceptance Test (FAT) for 450kVA oil immersed transformer begins with routine visual dimensional nameplate accessory and coating checks then insulation resistance polarization index tan-delta measurements. Separate-source withstand voltage (e.g. 28-35kV/1min for 11kV class) and induced overvoltage tests confirm major insulation with PD <10pC. Winding DC resistance corrected to 75°C verifies continuity and joint integrity. Voltage ratio phase displacement vector group (Dyn11 etc.) and polarity tested across taps with high accuracy. No-load loss exciting current and harmonics measured at rated voltage ensuring low no-load performance and current compliance.

Routine Test - Transformer Turns Ratio/TTR (All Tap Voltages)

Voltage source: usually AC 10 V to 30 V , used to test different voltages for each tap.

Temperature and humidity meter: used to record environmental conditions during the test to ensure test accuracy.

Current probe: used to measure the load current of the winding and ensure the accuracy of the test results.

Perform the test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C). Avoid high humidity or bad weather that may affect the test accuracy.

The voltage ratio between the windings

Deviation of the measured value from the rated ratio

0.5% < Turns ratio error ≤ 1% (caution)

Turns ratio error > 1% (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.