Armored Cable: A Complete Guide to Structure, Applications, and Installation

Armored cables play a crucial role in various complex and high-risk applications. Their core advantage lies in the significantly enhanced mechanical strength and environmental adaptability achieved through the metallic armor layer. Compared to ordinary power cables, armored cables can resist external impacts, pressure, abrasion, and rodent damage, making them widely used in underground tunnels, cable tray systems, chemical plants, mines, outdoor installations, and data communication networks. Their armor structure can employ steel tape armor, steel wire armor, or aluminum tape armor, with different structures selected based on the laying environment and load conditions. Steel wire armor is suitable for scenarios with high longitudinal stress, steel tape armor is suitable for fixed installations, while aluminum armor is often used for lightweight and corrosion-resistant applications. Thanks to their excellent tensile, compressive, and corrosion resistance properties, armored cables not only improve the overall reliability of the system but also extend their service life, providing stable and safe operation for power and communication networks. This makes them an indispensable component in modern infrastructure construction.

From an engineering perspective, armored cables are selected when electrical circuits or communication lines are exposed to harsh physical conditions. For example, armored electrical cable is widely used in factories where machinery vibration or mechanical contact can damage traditional cables. Similarly, armored fiber optic cable and armored fiber cable protect delicate optical fibers from crushing forces during installation or accidental excavation. For residential and commercial wiring, 12 2 armored cable is commonly used to meet building safety codes.

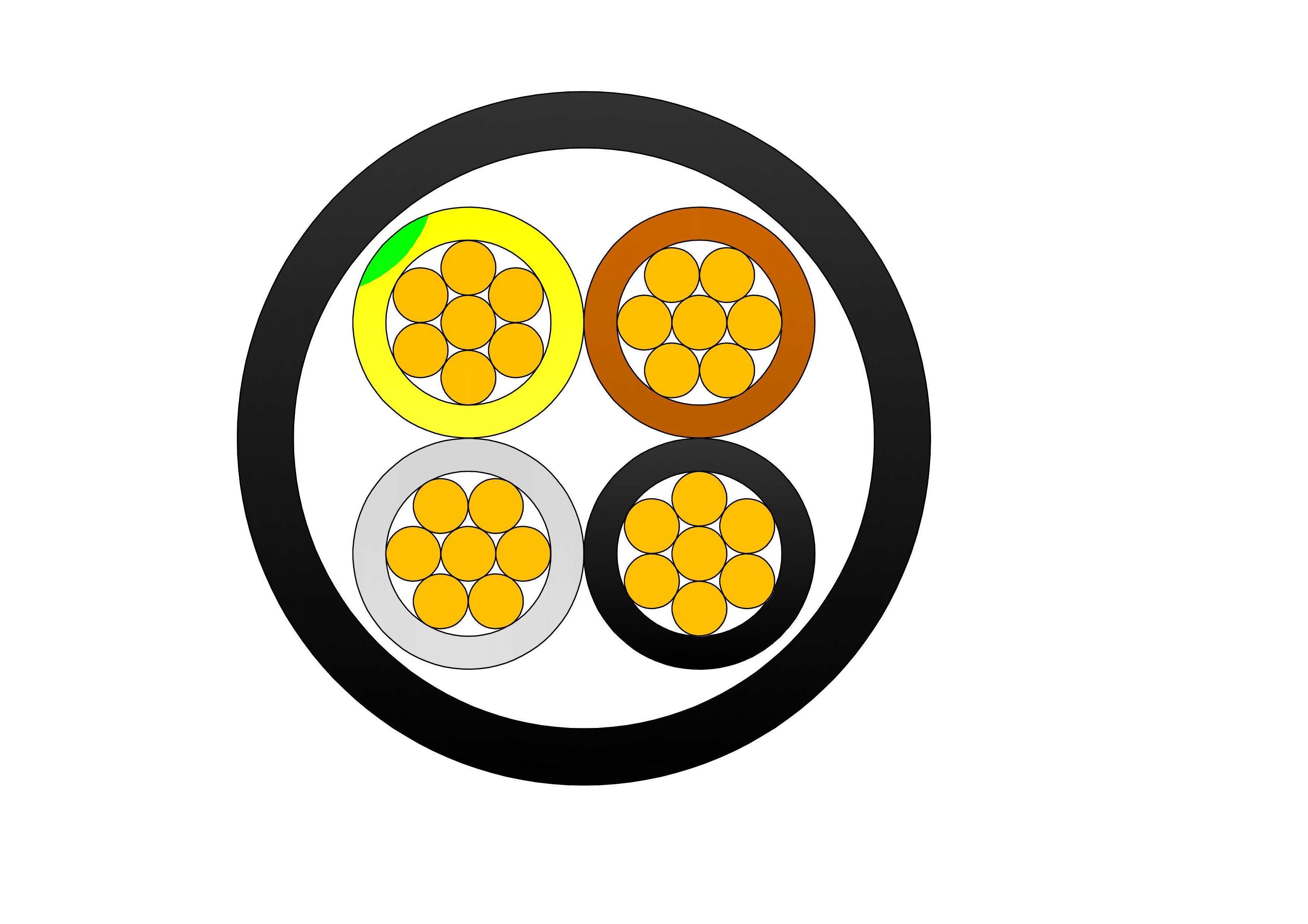

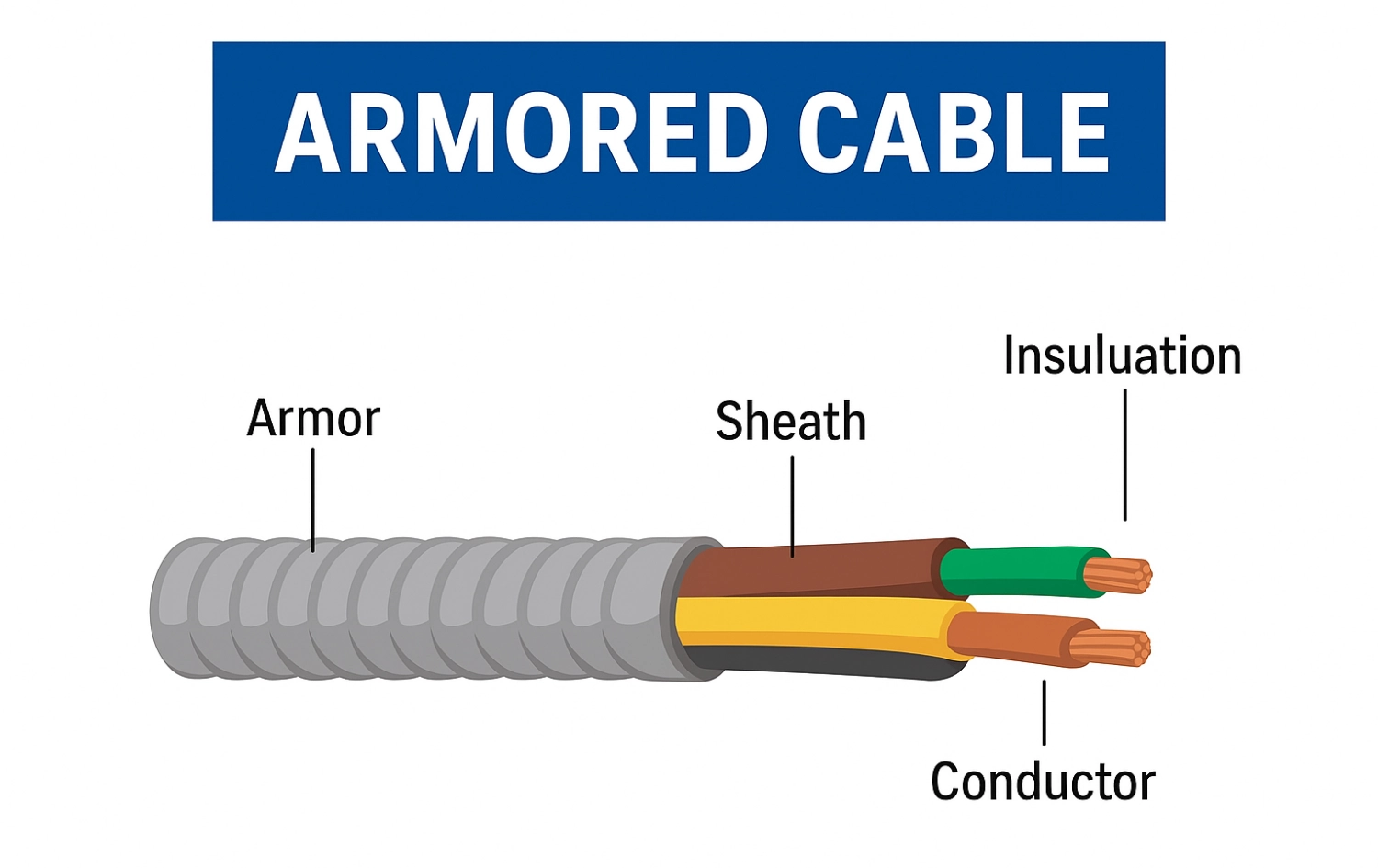

1. What Is an Armored Cable?

An armored cable is a type of electrical or communication cable wrapped with a protective metal layer. The armor does not conduct electricity but acts as a protective shield to prevent damage from external forces. Depending on the application, armor materials may include:

- Steel Wire Armor (SWA) for tensile strength and impact resistance

- Steel Tape Armor (STA) for underground installations with high mechanical load

- Aluminium Armored Cable for corrosion resistance and lightweight construction

In electrical engineering and construction projects, armored cables are essential for ensuring system reliability, especially where installation conditions pose risks like vibration, water exposure, or soil pressure.

2. Types of Armored Cable

Different armored cable types are optimized for electrical power, communication, or control systems. Below are the most commonly used variations:

(1) Armored Electrical Cable

Used in:

- Industrial power distribution

- Building wiring

- Underground feeders

Common variants:

- Copper core armored cable

- Aluminium armored cable (lighter, more cost-effective)

(2) Armored Fiber Optic Cable

Designed for telecommunication systems requiring high-speed data transmission with physical protection.

Advantages:

- Protects fiber from rodent bites

- Prevents micro-bending and crushing

- Suitable for direct burial installation

(3) 12/2 Armored Cable

A standardized cable size used in residential and commercial electrical wiring.

Features:

- Two insulated conductors + one ground

- Steel-armed jacket

- Fire-resistant and code-compliant

(4) Armored Control and Instrumentation Cables

Used for automation, sensors, and power control systems.

3. Technical Structure of Armored Cable

📘 Armored Cable Technical Comparison Table

|

Cable Type |

Armor Material |

Typical Application |

Key Features |

|

Armored Electrical Cable |

Steel wire (SWA) / Steel tape (STA) |

Power distribution, industrial wiring |

High mechanical protection, suitable for underground |

|

Aluminium Armored Cable |

Aluminum wire armor |

Corrosive or coastal environments |

Lightweight, corrosion-resistant |

|

Armored Fiber Optic Cable |

Corrugated steel tape + gel or dry core |

Telecom, data centers, outdoor fiber networks |

Crush-resistant, rodent-proof |

|

12 2 Armored Cable |

Steel interlocked armor |

Residential & commercial electrical wiring |

Fire-resistant, NEC-compliant |

|

Armored Control Cable |

Steel tape armor |

Industrial automation |

Good EMC shielding, durable |

4. Advantages of Armored Cable in Industrial Projects

(1) Mechanical Protection

Armor prevents:

- Impact damage

- Crushing by soil pressure

- Rodent bites

- Abrasion during installation

(2) Improved Safety

Armored cables greatly reduce electrical hazards by maintaining insulation integrity even in harsh conditions.

(3) Cost-Effective in the Long Term

Although more expensive upfront, armored cables reduce:

- Maintenance cost

- Replacement frequency

- Downtime in manufacturing or power systems

(4) Fire Resistance

Many armored cables are designed with:

- Fire-retardant jackets

- Heat-resistant insulation

- Self-extinguishing materials

(5) Versatility Across Environments

Suitable for:

- Underground installations

- Wet or chemical environments

- Outdoor use

- High-vibration zones

5. Applications of Armored Cable

Armored cables are widely used in:

- Power plants

- Oil & gas facilities

- Mines

- Airports

- Residential buildings

- Renewable energy (solar, wind)

- Data centers and telecom towers

Their robust performance makes them essential in both the electrical and communication industries.

6. Installation Considerations

To ensure safe and long-lasting performance:

- Avoid bending beyond the cable's minimum bending radius.

- Ensure proper grounding of metallic armor.

- Use approved cable glands for armored connectors.

- Protect cables from sharp edges during installation.

- Verify compliance with local electrical codes (IEC, NEC, GB/T).

Proper installation ensures the armored layer performs its protective function without imposing stress on internal conductors.

Armored cable is a vital solution for environments where electrical or communication circuits must endure mechanical stress, moisture, or external hazards. With options such as armored fiber optic cable, aluminium armored cable, and 12 2 armored cable, engineers can select the appropriate type for industrial, commercial, or residential projects. When chosen and installed correctly, armored cable significantly enhances safety, reliability, and long-term performance in modern power and communication systems.

2Y-high-voltage-power-cable-2.webp)