Wires and Cables

Control and Instrument Cable

Instrumentation Cables—XLPE Insulated, Overall Screened, Wire Armoured PVC Sheathed Cables(CU/XLPE/OSCR/SWA/PVC)

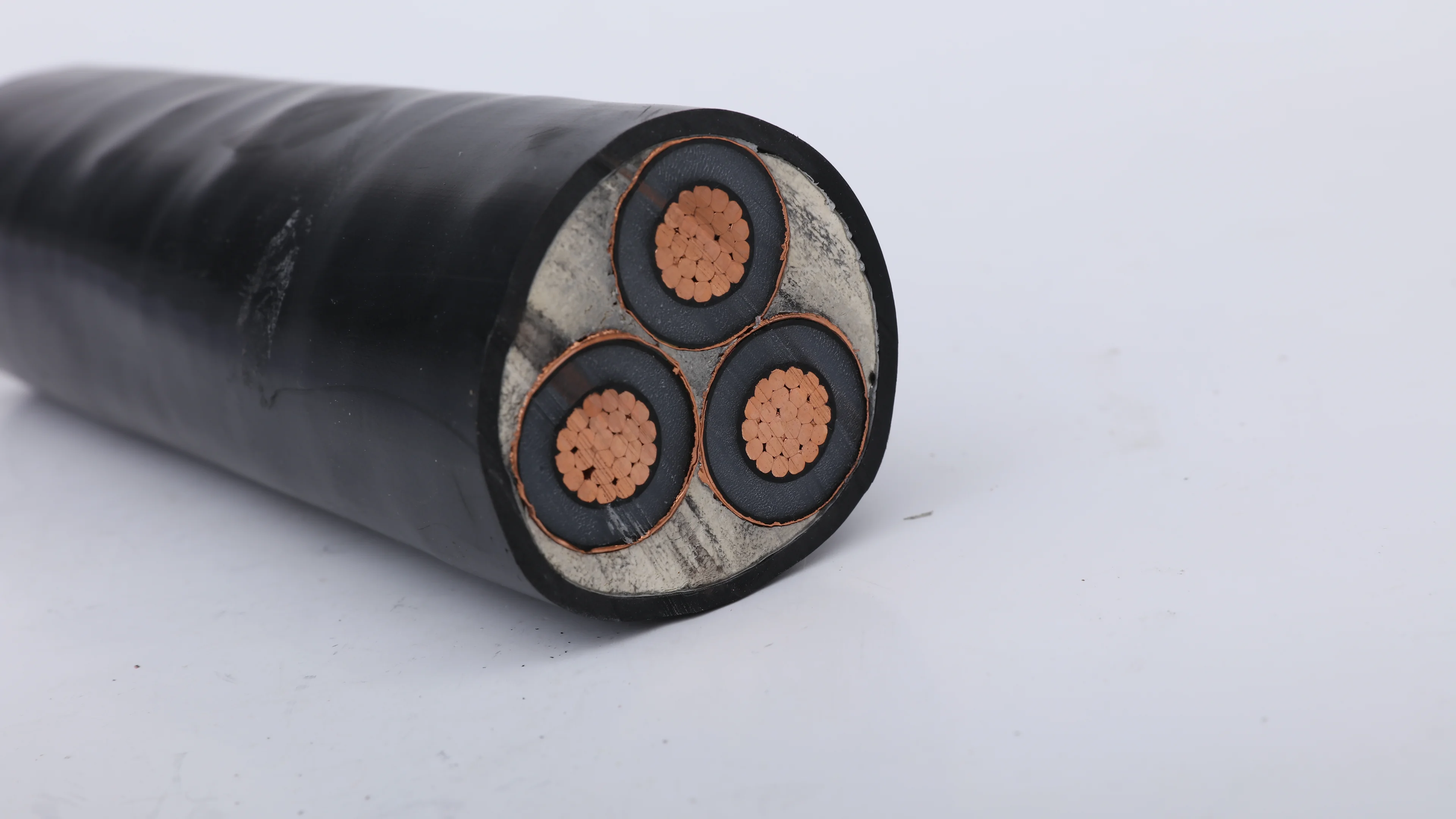

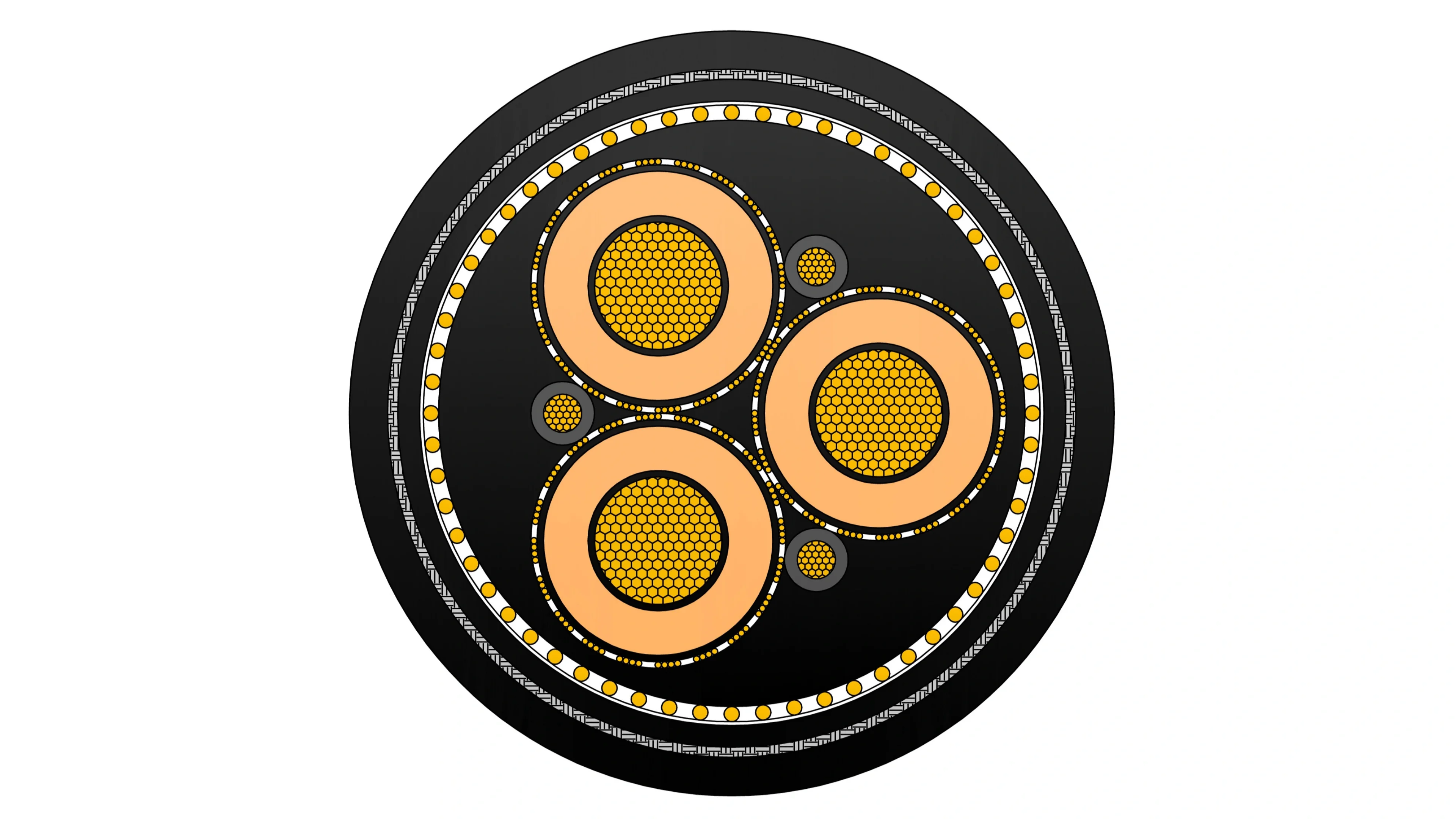

Engineered for thermal resilience and electromagnetic shielding, the Instrumentation Cables—XLPE Insulated, Overall Screened, Wire Armoured PVC Sheathed Cables (CU/XLPE/OSCR/SWA/PVC) excel in high-temperature environments. Stranded copper conductors ensure low resistance and flexibility, with XLPE insulation providing 90°C continuous rating and 250°C short-circuit tolerance. Overall screening via aluminum/polyester tape and drain wire mitigates EMI/RFI, preserving signal quality. SWA armour protects against mechanical damage, while PVC sheath adds flame resistance and waterproofing. Meeting BS EN 50288-7 and BS EN 50288-1 standards, these multi-pair cables transmit analogue/digital signals with low capacitance in demanding circuits. Suitable for ducts, trays, direct burial, or outdoor exposures, they boost system integrity and reduce interruptions in heat-intensive areas. With enhanced dielectric properties and attenuation control, this CU/XLPE/OSCR/SWA/PVC offers dependable, maintenance-reducing solutions for professionals in petrochemical, power, and industrial sectors.

Instrumentation Cables—XLPE Insulated,Individual & Overall Screened, Wire Armoured PVC Sheathed Cables(CU/XLPE/IOSCR/SWA/PVC)

Tailored for resilience under thermal and mechanical stress, the Instrumentation Cables—XLPE Insulated, Individual & Overall Screened, Wire Armoured PVC Sheathed Cables (CU/XLPE/IOSCR/SWA/PVC) ensure accurate signal transmission in challenging conditions. Stranded copper conductors offer low resistance and bendability, with XLPE insulation enabling 90°C continuous use and 250°C short-circuit resistance. Dual screening—individual for crosstalk minimization and overall aluminum/polyester with drain wire for EMI/RFI blocking—safeguards data integrity. SWA armour defends against physical hazards, while PVC sheath provides flame resistance and waterproofing. Adhering to BS EN 50288-7 and BS EN 50288-1, these multi-pair/triad cables handle analogue/digital circuits with reduced capacitance, supporting complex systems. Versatile for ducts, direct burial, or outdoor exposures, they improve uptime, cut failures, and enhance efficiency in heat-prone areas. With superior thermal stability and insulation properties, this CU/XLPE/IOSCR/SWA/PVC is essential for professionals needing armoured, dual-screened solutions that minimize costs and maximize performance in industrial sectors.

Instrumentation Cables—Mica Tapped, XLPE Insulated, Overall Screened, Wire Armoured LSZH Sheathed Fire-Resistant Cables(CU/GMT/XLPE/OSCR/SWA/LSZH)

Instrumentation Cables with Mica Taped, XLPE Insulated, Overall Screened, Wire Armoured and LSZH Sheathed construction (CU/GMT/XLPE/OSCR/SWA/LSZH) are designed for critical signal transmission in fire-risk and safety-sensitive environments. The copper conductor is wrapped with mica tape to maintain circuit integrity under fire conditions, while XLPE insulation ensures stable electrical performance and thermal resistance. The overall screen reduces electromagnetic interference, enabling accurate signal transmission in industrial systems. Steel wire armouring provides mechanical protection against impact and external stress, making the cable suitable for harsh installation conditions. The LSZH outer sheath limits smoke emission and toxic gases during fire, enhancing personnel safety. These fire-resistant instrumentation cables are widely used where continuous operation and reliable signal control are essential, even in extreme conditions.

Instrumentation Cables—Mica Tapped, XLPE Insulated, Individual &Overall Screened, Wire Armoured LSZH Sheathed Cables(CU/GMT/XLPE/IOSCR/SWA/LSZH)

CU/GMT/XLPE/IOSCR/SWA/LSZH instrumentation cables are engineered for precise signal and control transmission in environments with high electrical noise and strict safety requirements. The mica tape layer protects the copper conductor during fire exposure, while XLPE insulation ensures stable electrical characteristics and heat resistance. Individual screening of each circuit, combined with an overall screen, provides superior protection against electromagnetic interference, enabling accurate and stable signal performance. Steel wire armour enhances mechanical durability and protects the cable from external damage. The LSZH sheath limits smoke emission and corrosive gases, making the cable suitable for enclosed and public installations. This robust design makes the cable ideal for complex industrial applications requiring both signal integrity and safety compliance.

Instrumentation Cables—XLPE Insulated, Overall Screened, Lead Sheathed, Wire Armoured,PVC Sheathed Cables(CU/XLPE/OSCR/LEAD/SWA/PVC)

Instrumentation Cables with XLPE Insulated, Overall Screened, Lead Sheathed, Wire Armoured and PVC Sheathed construction (CU/XLPE/OSCR/LEAD/SWA/PVC) are designed for reliable signal and control transmission in harsh and corrosive environments. The copper conductor combined with XLPE insulation provides excellent electrical performance, thermal stability, and long service life. The overall screen effectively reduces electromagnetic interference, ensuring accurate signal transmission in complex industrial systems. A continuous lead sheath offers superior protection against moisture ingress, chemical attack, and hydrocarbon exposure. Steel wire armour enhances mechanical strength, making the cable suitable for demanding installation conditions. The outer PVC sheath provides additional environmental and mechanical protection. These instrumentation cables are widely used where durability, signal integrity, and environmental resistance are essential.

Instrumentation Cables—XLPE Insulated,Individual & Overall Screened,Lead Sheathed,Wire Armoured PVC Sheathed Cables(CU/XLPE/IOSCR/LEAD/SWA/PVC)

Instrumentation Cables are multi-conductor cables that carry and transport low-voltage electrical signals. These low-voltage signals are used to control and monitor electrical power systems. Instrumentation cables have many different industrial applications that include broadcasting, equipment control, such as drilling and pumping in the oil and gas industry, and data transfer, which includes analog and digital signals. They are manufactured according to the BS EN 50288-7 and BS EN 50288-1 standards to ensure quality. Depending on the application, instrumentation cables can be insulated with PVC or XLPE; the cables can be armoured or unarmoured. The sheathing materials can be of PVC, LSZH, or PE. The cables can have additional flame retardant or flame retardant properties, and they can be manufactured with special protections such as lead sheaths, or DRYLAM or AIRBAG technology.

Instrumentation Cables—XLPE Insulated, Overall Screened, DRYLAM Layered, Wire Armoured PVC Sheathed Cables(CU/XLPE/OSCR/DRYLAM/SWA/PVC)

CU/XLPE/OSCR/DRYLAM/SWA/PVC instrumentation cables are engineered to deliver stable signal transmission under harsh environmental and mechanical conditions. XLPE insulated copper conductors provide excellent dielectric performance and resistance to thermal aging. The overall screen minimizes electromagnetic interference, ensuring precise signal transmission in sensitive instrumentation circuits. The DRYLAM water-blocking layer offers effective protection against moisture ingress, enhancing cable reliability in humid or buried installations. Steel wire armour improves resistance to mechanical stress and external damage, while the PVC sheath protects against abrasion, oils, and chemicals. This balanced construction combines electrical performance, water resistance, and mechanical durability for long-term industrial use.

Instrumentation Cables—XLPE Insulated,Individual & Overall Screened, DRYLAM Layered,Wire Armoured PVC Sheathed Cables(CU/XLPE/IOSCR/DRYLAM/SWA/PVC)

Instrumentation Cables with XLPE Insulated, Individual & Overall Screened, DRYLAM Layered, Wire Armoured and PVC Sheathed construction (CU/XLPE/IOSCR/DRYLAM/SWA/PVC) are engineered for high-accuracy signal transmission in harsh and moisture-prone environments. XLPE insulated copper conductors deliver excellent dielectric strength, thermal stability, and long-term electrical reliability. Individual and overall screening effectively suppress electromagnetic interference and cross-talk, ensuring stable and precise signal performance in complex control systems. The integrated DRYLAM water-blocking layer prevents longitudinal and radial water penetration, protecting the cable core without increasing overall diameter. Steel wire armour provides strong mechanical protection against impact and external stress, while the PVC outer sheath offers resistance to abrasion, oils, and chemicals. This robust cable design ensures dependable operation, extended service life, and consistent performance in demanding industrial applications.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, NPC control & instrument cable exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

NPC control & instrument Cable have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

Control & Instrument Cable Manufacturer

Control Cable Applications

Instrument Cable Applications

Testing & Quality Control

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

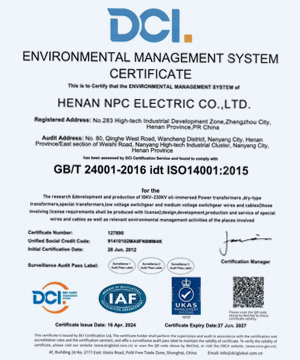

ISO Quality Certificate

ISO Environmental Certificate

ISO Occupational Certificate

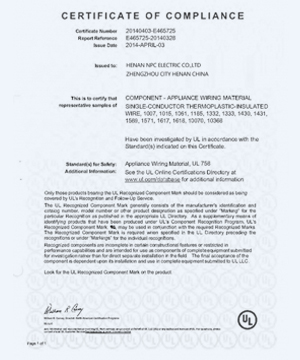

UL Laboratory Certificate

UL Product Certificate

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

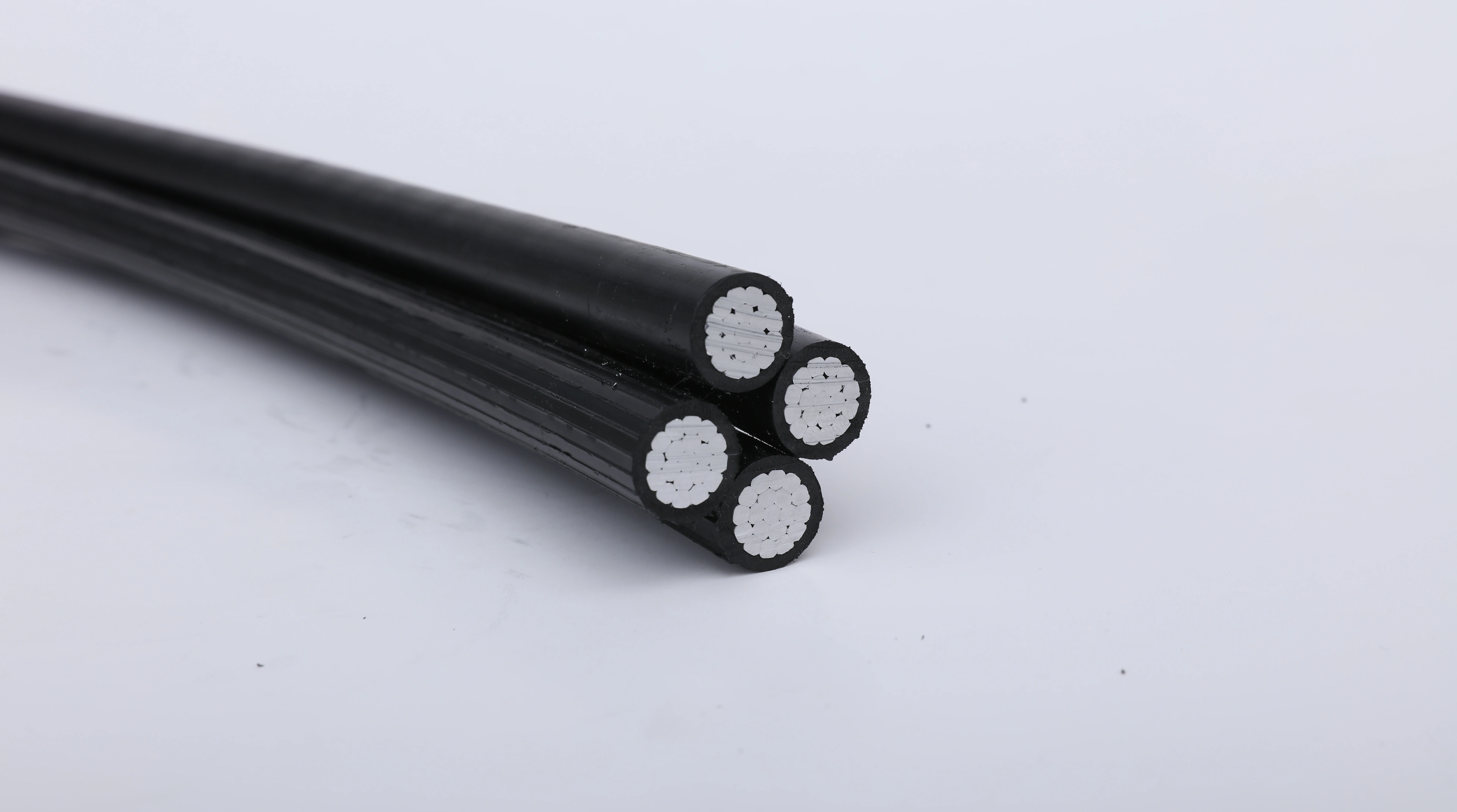

Model:NPC AAAC Cable & Triplex Cable x 10km

Technical Advantages

FAQ From Customers

-

What is a control cable?

A control cable is an electrical cable designed for the transmission of control signals in automation systems and electrical control systems. It is commonly used to connect control devices such as motors, sensors, and controllers in industrial applications. Control cables are made from copper or aluminum conductors and typically feature insulation to prevent electrical interference and ensure safe operation in low voltage circuits. These cables are essential for controlling and monitoring the functioning of machinery and electrical equipment. -

What is the difference between electrical power cable and control cable?

The main difference between electrical power cables and control cables lies in their function and design. Electrical power cables are designed to carry large amounts of electricity for power transmission across long distances, typically at higher voltages. In contrast, control cables are used for signal transmission to control or monitor equipment, often carrying low-voltage signals for devices such as controllers and sensors. Power cables are designed for high current handling, while control cables focus on low voltage, data transmission, and signal integrity. -

What are the applications of instrument cables?

Instrument cables are primarily used for signal transmission in instrumentation and measurement systems. These cables are designed to carry low-voltage signals from sensors to controllers, ensuring accurate data transmission in industries such as oil and gas, chemical processing, automated manufacturing, and telecommunications. Instrument cables are essential for providing reliable communication between electrical equipment and monitoring systems, ensuring the precision and efficiency of control systems. -

Where are control cables typically used?

Control cables are widely used in industrial automation systems, machinery control, power plants, and building systems. They are commonly found in manufacturing plants for controlling motors, valves, actuators, and other equipment. Control cables are also used in home automation systems, lighting control circuits, and security systems to transmit control signals from controllers to connected devices. Their versatility makes them crucial for any system requiring signal transmission for operational control. -

What materials are used in the construction of control and instrument cables?

Both control cables and instrument cables are typically constructed with copper or aluminum conductors for excellent electrical conductivity. Instrument cables often use shielding such as braided copper or aluminum foil to protect against electromagnetic interference (EMI) and ensure reliable signal transmission. The insulation materials used for both types of cables include PVC, XLPE (cross-linked polyethylene), and EPR (ethylene propylene rubber), providing protection against moisture, heat, and abrasion. The outer sheath is usually made of PVC or PE, offering additional protection for the cable.