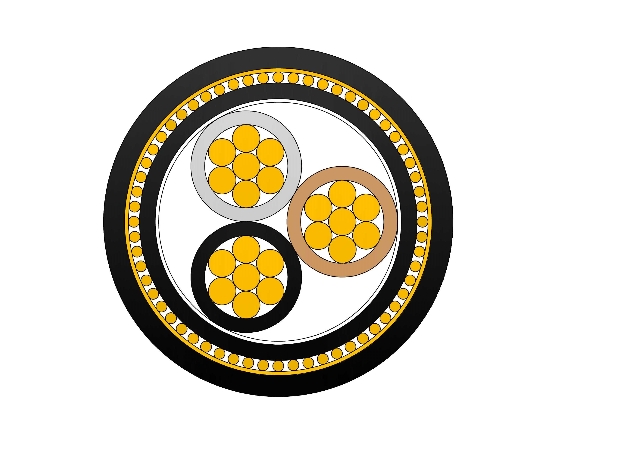

2 Cockle Aluminum Conductor Triplex Overhead Service Drop Cable

Construction

Standard

• ASTM B-231 Aluminum Conductors, Concentric-Lay-Stranded.

• ASTM B-232 Aluminum Conductors, Concentric-Lay-Stranded, Coated Steel Reinforced (ACSR).

• ASTM B-399 Concentric-Lay-Stranded 6201-T81 Aluminum Alloy Conductors.

• ICEA S-76-474-Neutral-supported Power Cable Assemblies With Weather-Resistant Extruded Insulation Rated 600 Volts.

Phase Conductor

Neutral (Messenger) Conductor

Insulation

Key Features

2. Temperature rating: 75°C (PE), 90°C (XLP)

3. Conductors: 1350-H19 Aluminum, stranded or compressed

4. Bare AAAC messenger for neutral and support

5. Insulation: Weather-resistant Black XLPE

6. Flexible design for easy stringing and tensioning

Application

Technical Specifications

| Rated voltage | V | 600 |

| Test voltage | Veff kV/Hz | 4/50 |

| Laying temperature | °C | min. -5 |

| Operating temperature | °C | -30 ~ +90 |

| Conductor temperature | °C | max. +90 |

| Short-circuit temperature | °C/s | max. +250 /5 |

| Bending radius (min.) | mm | 20 × Ø of cable |

Quality Control

Raw Material Test

Raw materials for 2-2-4 Cockle Aluminum Conductor Triplex Overhead Service Drop Cable undergo a thorough incoming inspection. 1. Aluminum rods (1350-H19 grade) analyzed via optical emission spectroscopy for ≥99.5% purity, impurities (Fe, Si ≤0.1%); conductivity (>61% IACS), tensile strength (>170 MPa), and elongation verified per ASTM B-233. 2. ACSR neutral messenger steel core wires tested for zinc coating thickness (Class A galvanization) and breaking strength per ASTM B-498 and B-232. 3. XLPE insulation compound checked for density, melt flow index, tensile strength (>8 MPa after aging), elongation (>200%), and carbon black content for UV protection per ASTM D-1248. 4. Visual and dimensional inspections detect surface defects or variations.

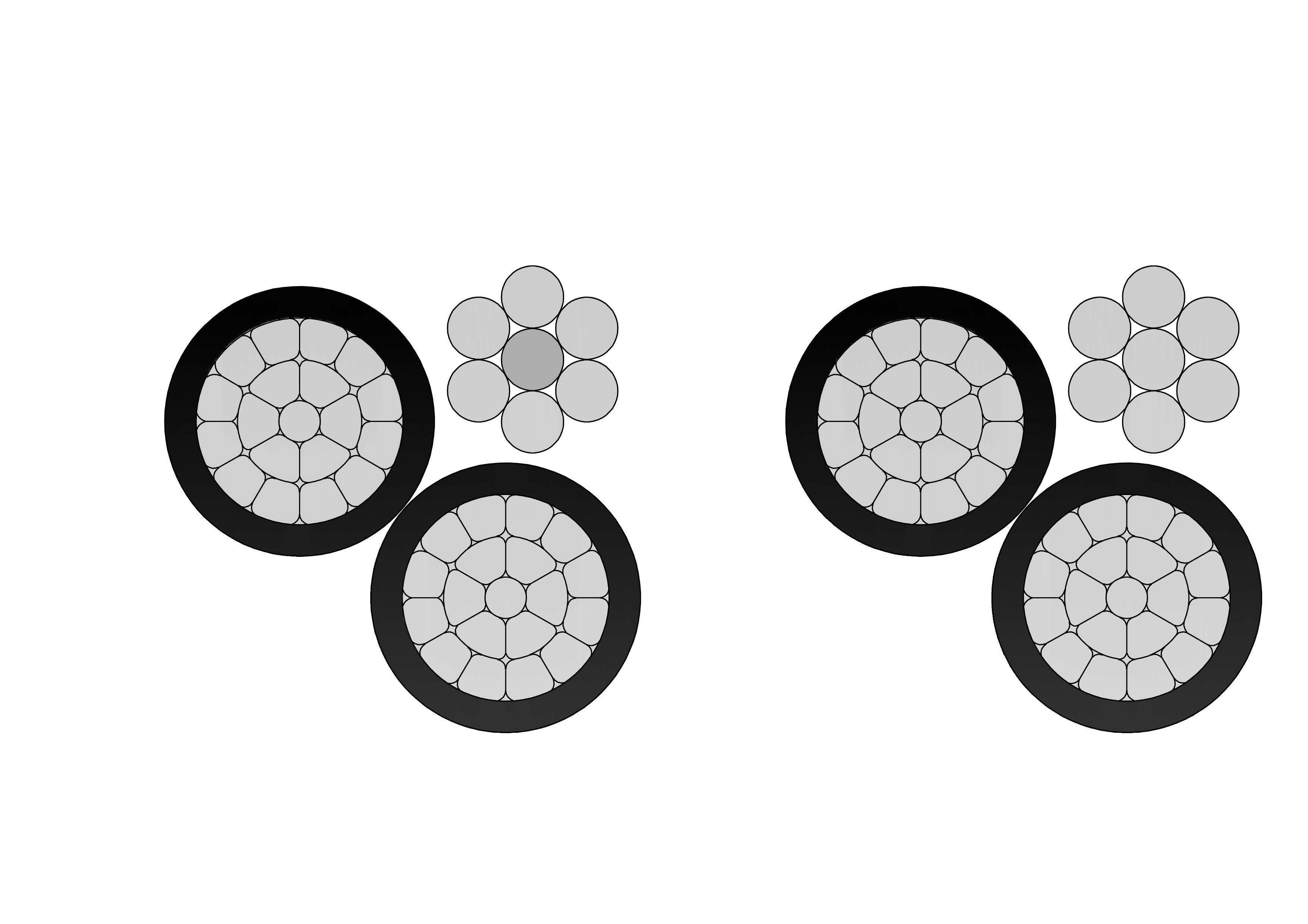

Process inspection

In-line monitoring during the manufacturing of 2-2-4 Cockle Aluminum Conductor Triplex Overhead Service Drop Cable maintains quality. 1. Stranding: Concentric stranding of #2 AWG phase conductors (7 wires) and #4 AWG ACSR neutral, checked for uniform lay length, no birdcaging, and proper tension. 2. Extrusion: XLPE insulation applied under controlled temperature/speed; online gauges confirm nominal thickness (≈0.050 inches) and concentricity, free of voids. 3. Cabling/twisting: Two insulated phases twisted around bare neutral at precise lay for balanced triplex configuration without insulation damage. 4. High-voltage spark testing scans continuously for pinholes or faults. 5. Periodic sampling evaluates conductor resistance, insulation integrity, and visual surface quality. Deviations trigger immediate line stops, adjustments, and hold procedures per ISO standards.

Finished Product

Final verification on completed 2-2-4 Cockle Aluminum Conductor Triplex Overhead Service Drop Cable includes: 1. Electrical: DC resistance per ASTM B-231 (max for #2/#4 AWG); insulation resistance >1000 MΩ-km at 500V DC. 2. Voltage withstand: AC high-potential test at 3kV for 5 minutes, no breakdown. 3. Physical: Insulation thickness/eccentricity measured microscopically; tensile strength and elongation of conductors/insulation meet ASTM specs. 4. Ampacity confirmed (~150A at 90°C XLPE). 5. Visual/dimensional inspection verifies print legibility ("Cockle", size, voltage, standards), no abrasions, and proper flexibility/coiling. 6. Sample mechanical bend and impact tests confirm durability. Results documented in detailed test reports; only compliant reels certified, labeled, and released.

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What are the advantages of power cables and overhead lines?(1) Reliable operation, because it is installed in a hidden place such as underground, it is less damaged by external forces, has less chance of failure, and the power supply is safe, and it will not cause harm to people; (2) The maintenance workload is small and frequent inspections are not required; (3) No need to erect towers; (4) Help improve power factor.

-

Which aspects should be considered when choosing the cross section of a power cable?(1) The long-term allowable working current of the cable; (2) Thermal stability once short circuited; (3) The voltage drop on the line cannot exceed the allowable working range.

-

What are the measures for cable fire prevention?(1) Use flame-retardant cables; (2) Use fireproof cable tray; (3) Use fireproof paint; (4) Fire partition walls and fire baffles are installed at cable tunnels, mezzanine exits, etc.; (5) Overhead cables should avoid oil pipelines and explosion-proof doors, otherwise local pipes or heat insulation and fire prevention measures should be taken.

-

What should be paid attention to during the transportation and handling of cables?(1) During transportation, loading and unloading, cables and cable reels should not be damaged. It is strictly forbidden to push the cable reels directly from the vehicle. Generally, cables should not be transported and stored flat. (2) Before transporting or rolling the cable reel, ensure that the cable reel is firm, the cable is wound tightly, the oil pipe between the oil-filled cable and the pressure oil tank should be fixed without damage, the pressure oil tank should be firm, and the pressure indication should meet the requirements.

-

What inspections should be carried out for the acceptance of cable lines?(1) The cable specifications should meet the regulations, the arrangement should be neat, no damage, and the signs should be complete, correct and clear; (2) The fixed bending radius of the cable, the related distance and the wiring of the metal sheath of the single-core power cable should meet the requirements; (3) The cable terminal and the middle head should not leak oil, and the installation should be firm. The oil pressure of the oil-filled cable and the meter setting should meet the requirements; (4) Good grounding; (5) The color of the cable terminal is correct, and the metal parts such as the bracket are completely painted; (6) There should be no debris in the cable trench, tunnel, and bridge, and the cover should be complete.

-AL-medium-voltage-power-cable.jpg)

2Y-high-voltage-power-cable.webp)

SSCHOU-mining-cable.webp)

2Y-high-voltage-power-cable.webp)