750kVA 3-Phase Oil-Immersed Outdoor Substation Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed transformer

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application Power Substations, Industrial Power Supply

- Power Rating 750kVA

- Certificate UL, CESI, IEEE

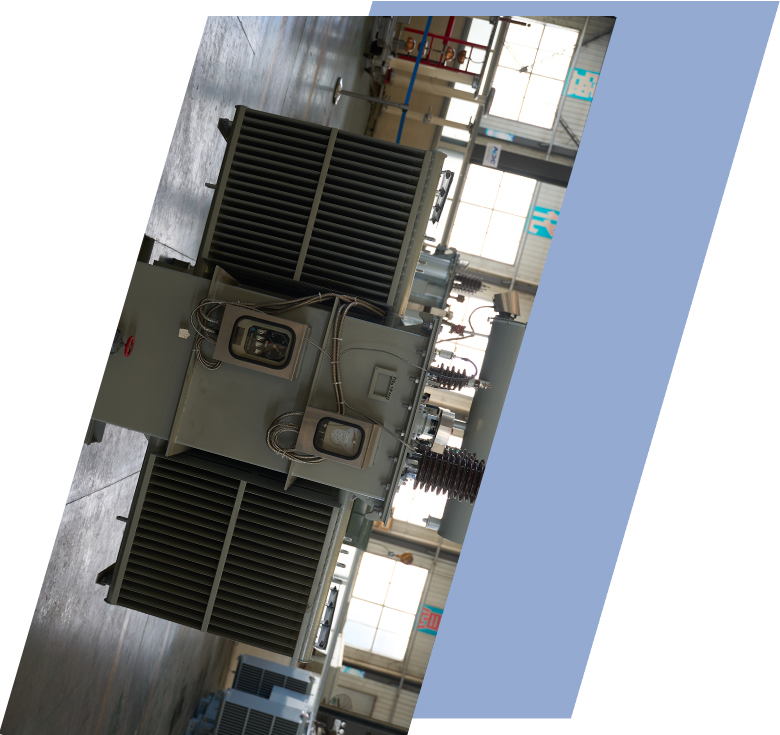

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 750 kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 900 kg | |

| Total Weight | 3100 kg | |

| Outline Dimensions(L×W×H)in. | 1950 × 1060 × 1900(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

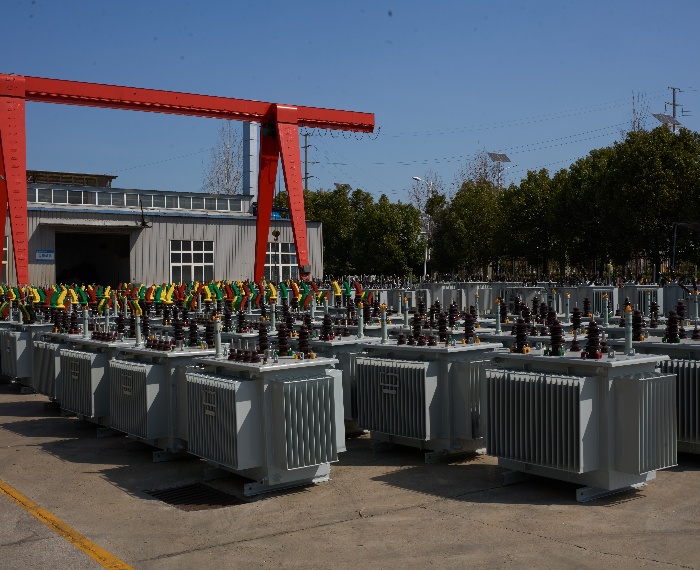

Packing and Shipping

After completing all factory routine, type, and special tests, the transformer is vacuum-treated and filled with high-purity nitrogen to maintain positive internal pressure throughout transit. This effectively prevents moisture ingress and oil oxidation during long-distance transportation. High-voltage and low-voltage bushings, oil level gauges, thermometers, sudden pressure relays, and other fragile accessories are carefully removed and packed in custom-made wooden crates lined with high-density anti-shock foam and desiccant for maximum protection.

The transformer body is securely mounted on a reinforced steel saddle skid designed for heavy load distribution. It is then fully enclosed in a robust wooden crate constructed from 12mm-thick marine-grade plywood and 50×50mm steel framing. The entire crate is double-wrapped with waterproof and moisture-proof film. All timber materials are IPPC-certified and fumigated with clear markings. The exterior is clearly labeled in English and Chinese with “750kVA 3-Phase Oil-Immersed Outdoor Substation Transformer,” lifting points, center-of-gravity indicators, handling instructions, and moisture warnings. Four high-precision shock recorders are attached to monitor impact and vibration throughout the journey.

For shipping, we offer flexible solutions including road transport via hydraulic modular trailers or low-bed trailers (total height controlled under 5 meters), sea freight in 40ft flat-rack containers or break-bulk under-deck stowage secured with DNV/GL-approved lashing using Φ18mm wire ropes and turnbuckles, and air freight options for urgent deliveries. Full documentation—including packing list, certificate of origin, fumigation certificate, nitrogen pressure report, shock recorder baseline data, and detailed installation manual—is provided with every shipment. With these rigorous measures, the 750kVA 3-Phase Oil-Immersed Outdoor Substation Transformer is guaranteed damage-free delivery worldwide, ready for immediate high-voltage power distribution installation.

Manufacturer Test

Progress Test

The 750kVA 3-Phase Oil-Immersed Outdoor Substation Transformer undergoes rigorous Progress Tests at critical manufacturing stages to guarantee superior quality and reliability. Following core-coil assembly, tests include winding insulation resistance (PI ≥ 2.0), DC resistance measurement at all taps, core grounding current (<50 mA), and preliminary no-load loss verification. Before tanking, the voltage ratio at every tap position (deviation ≤ ±0.5%) and vector group (Dyn11) are precisely confirmed to ensure electrical performance meets design specifications.

After vapor-phase drying and vacuum oil-filling, final insulation resistance, dielectric dissipation factor (tanδ ≤ 0.004 at 20℃), and partial discharge (<5 pC at 1.5Um/√3) are measured under witness. The completely assembled transformer then passes a 24-hour oil leakage test and a 0.35 bar positive/negative pressure test for 24 hours. All Progress Test records are fully documented and submitted for client or third-party approval, ensuring each 750kVA 3-Phase Oil-Immersed Outdoor Substation Transformer fully complies with IEC 60076 and project requirements before proceeding to final testing and delivery.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The 750kVA 3-Phase Oil-Immersed Outdoor Substation Transformer undergoes comprehensive Factory Acceptance Tests in strict accordance with IEC 60076, GB/T 1094, and project technical specifications, witnessed by client or third-party inspectors.

Key tests include:

- Winding resistance measurement at all tap positions

- Voltage ratio and phase displacement verification at principal, ±2.5% and ±5% taps (deviation ≤ ±0.5%)

- Vector group and polarity confirmation (Dyn11)

- No-load loss and no-load current at 90%, 100%, and 110% rated voltage

- Load loss and short-circuit impedance at rated current and principal tap (tolerance per IEC)

- Applied voltage test (separate-source withstand)

All results are recorded in the official FAT protocol, signed by the client representative upon acceptance, ensuring the transformer is fully qualified for high-voltage power distribution service.

Routine Test - Temperature Rise

Heating source

Temperature sensor

Voltage source

Temperature and humidity meter

Connect the test instrument correctly to the electrical terminals and temperature measurement points of the device under test . Ensure that the test system is well grounded to ensure test safety.

Initial condition record:

Measure and record ambient temperature, humidity, and atmospheric pressure at the start of the test.

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.