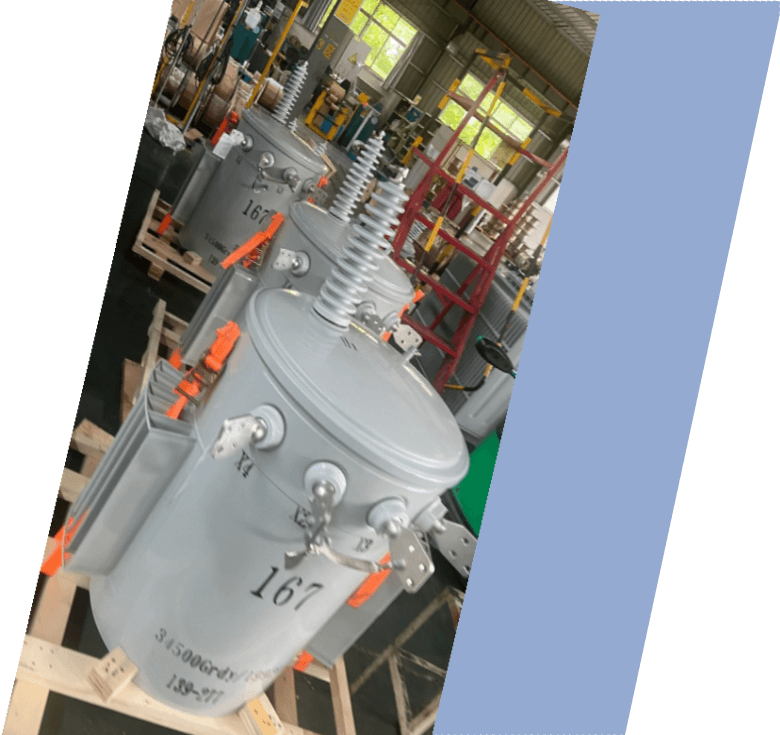

250kVA Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 2.4kV, 11kV, 33kV, 34.5kV

- Secondary Voltage Ratings 480-240/240-120 or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 30-150kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application workshops, public amenities, managing increased loads

- Power Rating 250kVA

- Certificate CE, ISO

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 250kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 168 kg |

| Total Weight | 780 kg |

| Outline Dimensions(W×D×H) | 825×910×1635 (mm) |

| Lifting Lug |

| Tap Changer |

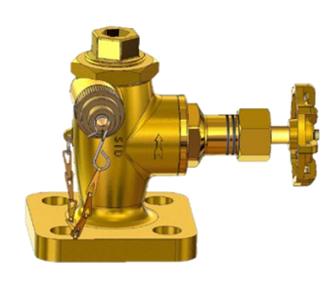

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

| Oil fill valve |

Customization Optional

Packing and Shipping

Transportation arrangements are customized for efficiency and security, with domestic shipments via specialized lowboy trailers equipped with securement chains and weatherproof covers to shield from road debris and elements. International consignments typically employ 40-foot open-top or flat-rack containers for oversized units, supplemented by lashing systems compliant with maritime standards. For urgent deliveries, air charter options are coordinated, though surface routes predominate due to dimensions. Continuous GPS tracking, coupled with comprehensive cargo insurance, provides peace of mind throughout the journey. Strict adherence to IEC, IEEE, and local regulations streamlines customs procedures, accelerating delivery timelines for the 250kVA single phase pole mounted transformer globally.

Our commitment to sustainability influences packing choices, favoring recyclable woods and minimal plastic usage while optimizing load configurations to lower transportation emissions. Impact monitors are affixed to crates to detect excessive forces, supporting post-arrival inspections and claims if required. Accessories such as radiators or control boxes are separately crated with individual checklists for easy verification. Partnering with logistics providers experienced in electrical apparatus ensures compliance with heavy-haul permits and safe routing through varied terrains.

Upon arrival, detailed instructions guide safe unloading and reassembly, including oil refilling procedures and torque values for connections. We offer coordination for on-site delivery, even to remote locations, minimizing installation delays. This end-to-end approach safeguards product integrity, reduces risks, and supports efficient deployment of the 250kVA single phase pole mounted transformer in critical power infrastructure projects worldwide.

Manufacturer Test

Progress Test

Throughout the production phases of the 250kVA single phase pole mounted transformer, progress tests commence with core material validation, assessing grain-oriented silicon steel for lamination thickness uniformity and surface insulation using epstein frame measurements to maintain no-load losses below specified limits. Winding process checks include turn counting accuracy and layer insulation verification via high-potential testing between consecutive layers at reduced voltage. Interwinding capacitance and dissipation factor are monitored during assembly to detect anomalies early. Ratio verification employs precision ratio meters on preliminary windings, ensuring deviations stay within 0.1% of design values. Core clamping pressure is gauged to prevent buckling, with vibration tests simulating transport stresses. Oil compatibility sampling confirms dielectric strength above 35kV and low moisture levels under 10ppm. Tank fabrication inspections use dye penetrant and radiographic methods on welds for leak-proof integrity, while mounting provisions are load-tested for structural soundness. All measurements are recorded digitally for traceability and trend analysis.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The factory acceptance test sequence for the 250kVA single phase pole mounted transformer initiates with comprehensive visual and dimensional verification against approved drawings, including tank finish, bushing alignment, and accessory placement. Winding DC resistance is measured using four-wire method at stabilized temperatures, corrected to 75°C with results within 1% of factory averages. Turns ratio and polarity are confirmed via automated TTR equipment across all tap positions, maintaining accuracy to 0.25%. Insulation power factor and capacitance testing at 10kV yields dissipation factors below 0.4%, indicating sound dielectric condition. No-load loss and exciting current measurements at rated voltage verify compliance with efficiency mandates, keeping excitation below 1.5% of rated current. Load loss determination through short-circuit method calculates total losses and impedance percentage precisely. Power frequency withstand voltage applies 50kV or equivalent to HV side for one minute without flashover. Induced potential test at higher frequency checks turn insulation integrity. Oil quality analysis includes breakdown voltage over 40kV and dissolved gas levels within acceptable norms.

Routine Test - Leak Test

Voltage source (usually 500V, 1 KV or 2.5 KV, customized according to test requirements)

Temperature and humidity meter

Ground electrode

Properly connect the test equipment (such as a leak detector) to the pipe, container or sealing structure of the device under test.

Apply Test Voltage:

Apply the appropriate test pressure (e.g. 10 bar, 15 bar, etc.) depending on the equipment's operating pressure or test standard.

Applied test pressure

Leakage (can be monitored by flow meter or other equipment)

Time record (to ensure that the test time meets the standard requirements)

Initial pressure and final pressure (if any changes)

Minor leakage (good): Very small leakage is allowed, and it is necessary to judge whether it is qualified according to industry standards.

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.