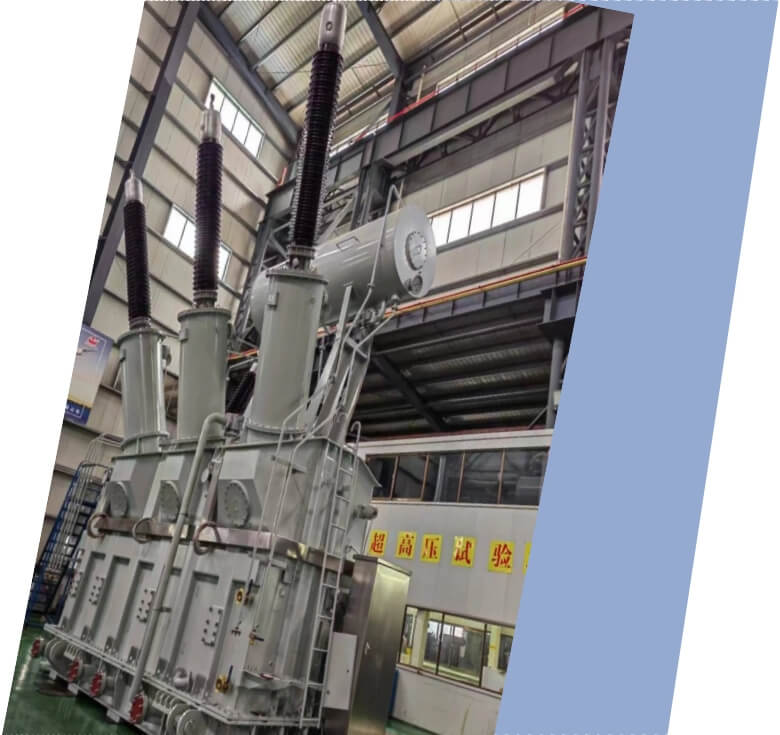

380kV Oil-Immersed Power Transformer

- Primary Voltage Ratings 220kV 230kV 380 kV

- Secondary Voltage Ratings 69/35/37/34.5/26.4./11/10.5/6.6/13.2 kV or others

- H.V. Tap Range ± 8×1.25% HV taps or others

- Type Oil-immersed power transformer

- BIL 900kV

- Standards IEEE, ANSI, IEC, GB

- Application long-distance transmission, renewable energy projects, solar energy

- Power Rating 5000-250000kVA

- Certificate UL, ISO, CESI

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 5000-250000kVA |

| Rating Primary Voltage | 220kV 230kV 380kV |

| Secondary Voltage |

69/35/37/34.5/26.4/11/10.5/6.6/13.2 kV Customized |

| Frequency | 50/60Hz |

| Vector Group | Dyn11, YD11, YNd11 or anothers |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE, CAS Std or Customized |

| Impedance Voltage | As IEC |

| Altitude | ≤1,000m or Customized |

| Enclosure material | Mid Steel |

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Customization Optional

Packing and Shipping

For inland transport, we utilize specialized multi-axle modular trailers (SPMT) capable of distributing the concentrated load of the main tank across dozens of wheels. This prevents damage to road infrastructure and ensures the stability of the transformer during transit. A comprehensive route survey is conducted prior to dispatch to identify clearance issues under bridges or power lines. The main body is secured using heavy-duty turnbuckles and steel chains, with friction mats placed underneath the tank to prevent any shifting during the dynamic forces encountered on a ship's deck or a moving heavy-load vehicle.

To ensure accountability and safety, we install a series of 3D impact recorders and GPS tracking units on the transformer tank. These devices provide real-time data on the unit's location and record any G-force impacts exceeding 2G in the longitudinal, transverse, or vertical axes. Upon arrival at the port of discharge or the final substation site, a joint inspection is carried out to verify that no internal displacement has occurred. This data-driven approach to shipping allows our engineers to confirm that the factory-set mechanical tolerances have been preserved before the installation process begins.

The final stage of shipping involves the "last mile" delivery to the transformer pad. Our specialized logistics team manages the complex task of offloading the unit, often using a "jack-and-slide" method if crane access is restricted. Once the transformer is positioned, the nitrogen is purged and replaced with processed insulation oil under a continuous vacuum to prevent air bubbles. This comprehensive end-to-end shipping strategy minimizes the risk of insulation degradation or mechanical fatigue, ensuring that the 380kV transformer arrives at the customer's site in the same pristine condition it left our testing bay.

Manufacturer Test

Progress test

NPC Electric's manufacturing process incorporates a rigorous Progress Test schedule at every critical assembly stage. This begins with the "Cold Test" of the core to verify flux density and magnetic symmetry. Once the windings are manufactured, we perform a high-precision turns ratio and polarity test to ensure electrical alignment. A critical stage is the "Vapor Phase Drying" (VPD) process, after which we measure insulation resistance and power factor to confirm total moisture removal from the cellulose materials. Finally, we conduct a pre-tanking inspection (Core-and-Coil assembly) to ensure all internal clearances and hydraulic connections for the cooling system meet the 380kV design criteria.

Design Tests

All transformers will be tested after finishing the production test items as below:

♦ Leak testing with pressure for liquid-immersed transformers

♦ Test of transformer oil

♦ Measurement of voltage ratio and check of phase displacement

♦ Measurement of winding DC resistance

♦ Measurement of d. c. Insulation resistance between each winding to earth, and check of the core and frame insulation

♦ Capacitive bushing test

♦ Measurement of dissipation factor (tan δ) of the insulation system capacitances, and determination of capacitances windings-to-earth

♦ Measurement of no-load loss and current at 90%,100%,110% of rated voltage

♦ Operation test on on-load tap-changer

♦ Measurement of short-circuit impedance and load loss

♦ Lightning impulse test

♦ Induced-voltage test with partial discharge measurement

♦ Auxiliary wiring check

♦ Current transformer test

♦ Frequency response analysis test

Transformer Factory Acceptance Test

The FAT for our 380kV units focuses on extreme electrical stress validation. We perform Lightning Impulse Tests (both full and chopped wave) and Switching Impulse Tests to simulate grid transients. This is followed by a long-duration Induced Overvoltage Test with Partial Discharge (PD) measurement, where PD levels must remain below 50pC. We also execute a full-load temperature rise test to ensure the oil and winding temperatures stay within the 60/65K limits.

Routine Test - DC Insulation Resistance Test

Voltage source (usually 500V, 1000V, 2500V, or customized according to customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test to ensure that the test conditions meet the standard requirements.)

Perform the test under suitable environmental conditions. It is recommended to have a relative humidity below 75%, no rain, and a temperature range of 20-30°C to avoid moisture or temperature fluctuations affecting the test results.

Connect an insulation resistance tester to the high voltage terminal of the device under test and to ground.

Apply Test Voltage:

Select an appropriate test voltage based on the rated voltage of the equipment .

Insulation resistance value (MΩ)

Applied voltage

Ambient temperature and humidity during testing

500 MΩ ≤ Insulation resistance < 1000 MΩ (good)

100 MΩ ≤ Insulation resistance < 500 MΩ

Insulation resistance < 100 MΩ

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.