44kV Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957, 24.94, 26.25, 44 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

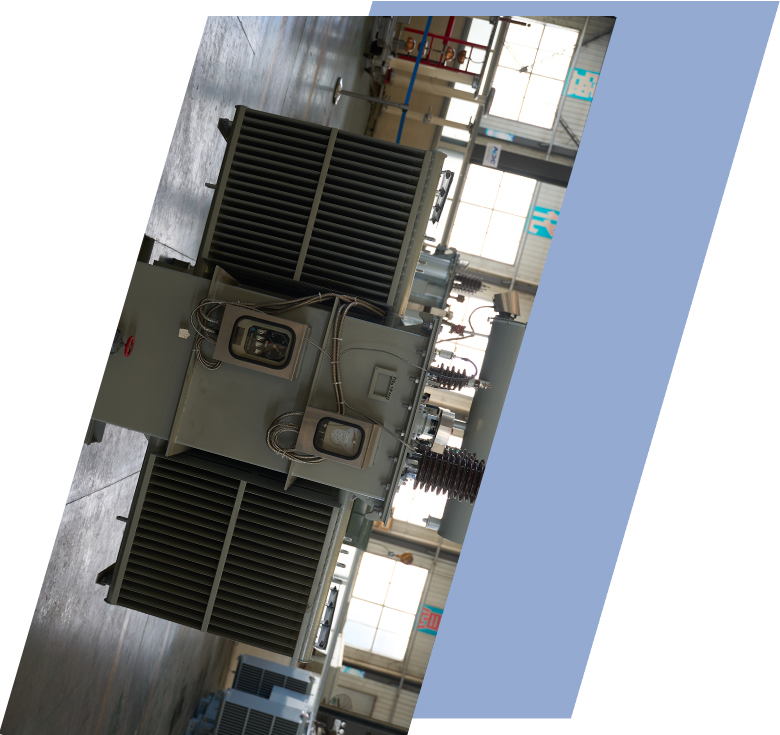

- Type Oil immersed distribution transformer

- BIL 44kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application power grids, large-scale agricultural power systems

- Power Rating 30kVA - 5000kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 30kVA - 5000kVA | |

| Rating Primary Voltage | 2.4 - 44kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 850 kg | |

| Total Weight | 5000 kg | |

| Outline Dimensions(L×W×H)in. | 2650 × 1650 × 2450(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

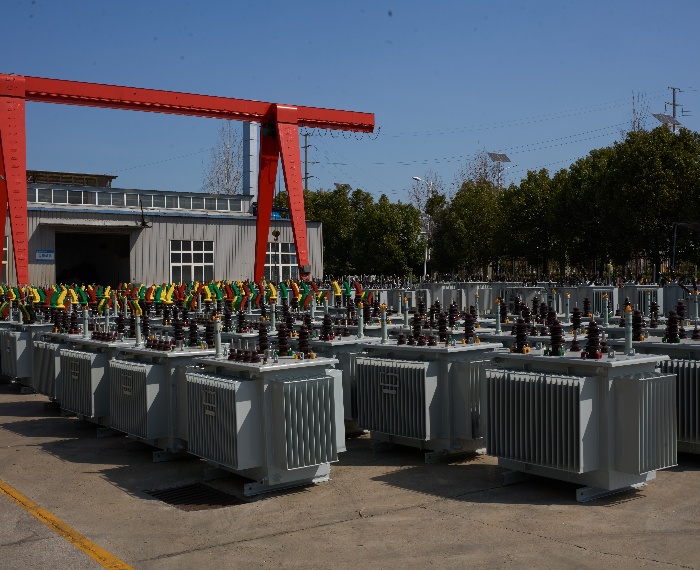

Packing and Shipping

Modular disassembly enhances protection: radiators/pumps detached and foam-cradled in separate crates, high-BIL bushings (resin-impregnated) housed in vibration-proof enclosures, OLTC assemblies immobilized with custom locks, and monitoring panels sealed in moisture-barrier bags with desiccants. The primary structure affixes to reinforced steel platforms or ISPM-15 wooden bases with engineered tie-downs, foam interleaves, and g-force rated cushions (up to 6g), incorporating electronic monitors for humidity, temperature, shock, and orientation logging.

For overseas shipments—dominant in global supply chains—cargo loads onto specialized flat-rack or heavy-lift vessels with IMO-certified strapping, UV/salt-resistant shrouds, and fumigation-free treatments; rail/road legs use articulated heavy-haulers with hydraulic suspensions for even weight spread and crane-accessible lugs. Documentation suite features multilingual invoices, conformity declarations, type/routine test dossiers, engineering schematics (assembly/lifting), fluid MSDS, export licenses, and HS codes (8504.23 for high-voltage units >650kVA).

End-to-end logistics management includes tailored routing (e.g., via Rotterdam for EU deliveries), real-time GPS tracking, insurance against all perils, and supplementary offerings like independent surveyor verifications, destination port handling, professional crane offloading, fluid reclamation/degassing, alignment inspections, and startup commissioning. This holistic methodology averts damage, upholds performance specs, satisfies trade compliances, and facilitates swift deployment for clients in transmission, renewable, and industrial sectors.

Manufacturer Test

Progress Test

Ester fluid progress testing scrutinizes synthetic batches for flash point, viscosity, oxidation stability, dissolved metals and eco-compliance per IEC 61099 with purification circuits yielding <5ppm impurities. Core-coil dehydration progress charts high-vacuum chamber dynamics, thermal ramps, and endpoint moisture extraction below -55°C for premium insulation class. Sealing and filling progress supervises ester impregnatio,n circulation de-aeration, overpressure nitrogen integration, and sustained vacuum decay assessments. Safeguard component progress calibrates sudden pressure relays, gas detectors, thermographic probes relief mechanisms, and OLTC positional accuracy. Pre-export progress compiles mass/volume metrics, aesthetic conformity identification tagging crate durability simulations and exhaustive visual/electronic dossiers affirming total adherence and defect-free status for consignment.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Load characterization shorts outputs imposes fractional inputs derives loss impedance (10-14%) efficiency contours and regulation profiles at ref temps for overload forecasting. Fluid assays verify dielectric (>65kV/2.5mm) contaminants acidity DGA pre-fault baselines absent hydrocarbons. Thermal emulation confirms oil/winding deltas (<55K/<70K) via abbreviated runs. Operational trials activate relief valves pressure sensors relay interlocks OLTC transitions and acoustic emissions (<65dB). Structural proofs include enclosure pressurization seal verifications bushing arcs and circuitry continuity. Exhaustive FAT compilations with metrology-traceable certs, elective observer endorsements validate IEC 60076 GB1094 IEEE conformance routine/special test endorsements before clearance.

Routine Test - Impulse Tests

Voltage divider (used to measure impulse voltage waveform, resistor divider or capacitor divider)

Oscilloscope (used to record impulse waveform, common brands such as Tektronix, Keysight)

Calibrate and check the impulse voltage generator, measurement system, and control system to ensure that the instruments and equipment are in good condition and meet the test standards.

Connect the impulse voltage generator correctly to each winding terminal (high voltage terminal, ground terminal) of the device under test, and ensure that all test instruments are well grounded.

Apply Test Voltage:

Select the appropriate impulse voltage waveform and amplitude according to the rated voltage of the equipment

Front Time

Time to Half-Value

Peak Voltage

Distortion

Ambient temperature and humidity (especially when the test environment needs to be corrected)

If the waveform deviation is too large, adjust the impulse generator parameters and reapply the test.

In special cases, inter-winding impact, voltage-to-ground impact or coil corner impact are performed (according to the test plan).

Waveforms are stable and meet standard specifications.

Waveform variations between repeated tests are minimal (usually good waveform overlap with no noticeable abnormal excursions).

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.