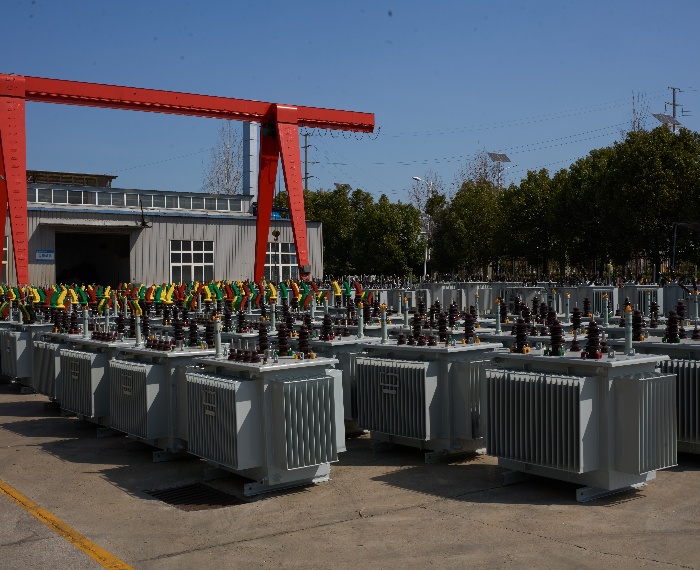

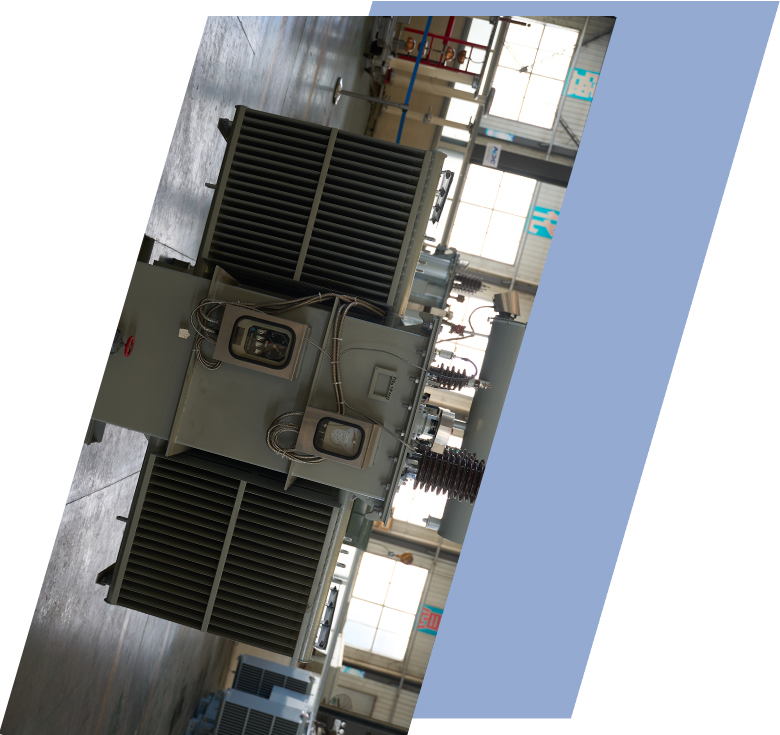

35kV Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957, 24.94, 26.25, 35 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed distribution transformer

- BIL 35kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application wind and solar new energy power station voltage boosting

- Power Rating 30kVA - 5000kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 30kVA - 5000kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 850 kg | |

| Total Weight | 5000 kg | |

| Outline Dimensions(L×W×H)in. | 2650 × 1650 × 2450(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

Packing and Shipping

Detached elements receive specialized protection: radiators crated with vibration-isolating foam, high-voltage bushings (RIP/porcelain) in reinforced shock-absorbent cases, OLTC drives secured and sealed, and auxiliary cubicles wrapped with desiccants against humidity. The core transformer body secures to heavy-duty steel bases or ISPM-15 certified wooden/steel cradles featuring custom internal bracing, lateral restraints, and impact-absorbing pads designed for 4-6g accelerations typical in multimodal transport. Multi-layer packaging uses weather-resistant tarpaulins, volatile corrosion inhibitors (VCI), humidity indicators, temperature monitors, and digital shock/tilt recorders for real-time handling traceability.

Primary export mode is ocean freight via flat-rack, open-top, or break-bulk carriers with IMO lashing standards, anti-salt fog barriers, and protective coverings; inland transport utilizes specialized heavy-haul trailers with distributed load cradles and designated lifting lugs. Complete export documentation includes invoices, detailed packing lists, certificates of origin/conformity, routine/type test reports, engineering drawings (dimensional/lifting), oil safety data sheets, installation guides, and HS code classifications (8504.23 for power transformers >650kVA).

We orchestrate full logistics solutions from origin to final destination, offering FOB/CIF/door delivery, customs clearance assistance, marine insurance coordination, and premium services like third-party witnessing, on-site rigging supervision, professional oil filtration/processing, transformer erection guidance, and commissioning tests. This meticulous strategy eliminates transit risks, preserves as-new condition, meets all regulatory requirements, and ensures timely, secure arrival for international utility, renewable, and industrial clients.

Manufacturer Test

Progress Test

Progress testing of 35kV oil immersed transformer initiates with silicon steel material certification verifying lamination gauge uniformity insulation coating magnetic properties and edge quality via Epstein sampling to secure minimal hysteresis/eddy losses then core assembly checks multi-step lap joints precise clamping torque shielding effectiveness and vibration damping. Winding production progress tracks conductor conductivity insulation wrapping density automated tension control layer accuracy and high-voltage inter-turn withstand post-winding. Core-coil integration progress confirms critical clearances barrier materials end-turn insulation and electromagnetic force-resistant clamping structures. Tank construction progress examines weld seam ultrasonic/NDT inspection hydrostatic overpressure holds (1.5x) surface preparation grit-blasting multi-coat epoxy/paint thickness.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Load loss impedance voltage and efficiency determination shorts secondary applies reduced primary voltage calculates copper losses percentage impedance (8-12%) and total losses at specified temperature for regulation/overload evaluation. Oil routine tests confirm dielectric strength (>60kV/2.5mm) moisture (<20ppm) acidity and initial DGA profile with no fault gases. Thermal performance indicators verify top-oil/winding temperature rise limits (e.g. <60K/<65K) through simulated or short-duration heat run. Functional checks include pressure relief device operation Buchholz/sudden pressure relay tripping temperature alarm settings OLTC sequencing smoothness and sound power measurement (<62dB). Mechanical validation encompasses tank overpressure endurance leak-free integrity bushing coordination and wiring continuity.

Routine Test - Applied Voltage

Voltage source: usually 1 kV, 5 kV, 10 kV, or customized according to customer needs

Temperature and humidity meter: used to record environmental conditions

Check the connection terminals and wiring to ensure that they are not loose or contaminated.

Test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C).

Properly connect the test equipment to the bushings or terminals of the device under test and ensure that all connection points are properly grounded.

Selecting the test voltage:

Select the appropriate applied voltage based on the rated voltage of the equipment.

Measuring leakage current

Applied voltage

Current stability

Any possible voltage fluctuations

The current value exceeded the allowable range and the equipment needs to be inspected or maintained (pending repair)

There was a serious fault or instability and the equipment could not continue to operate (unqualified)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.