630kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application heavy machinery, critical infrastructure, EV charging stations

- Power Rating 630kVA

- Certificate UL

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 630 kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 3500 kg |

| Total Weight | 9700 kg |

| Outline Dimensions(L×W×H)in. | 2880×2200×2100(mm) |

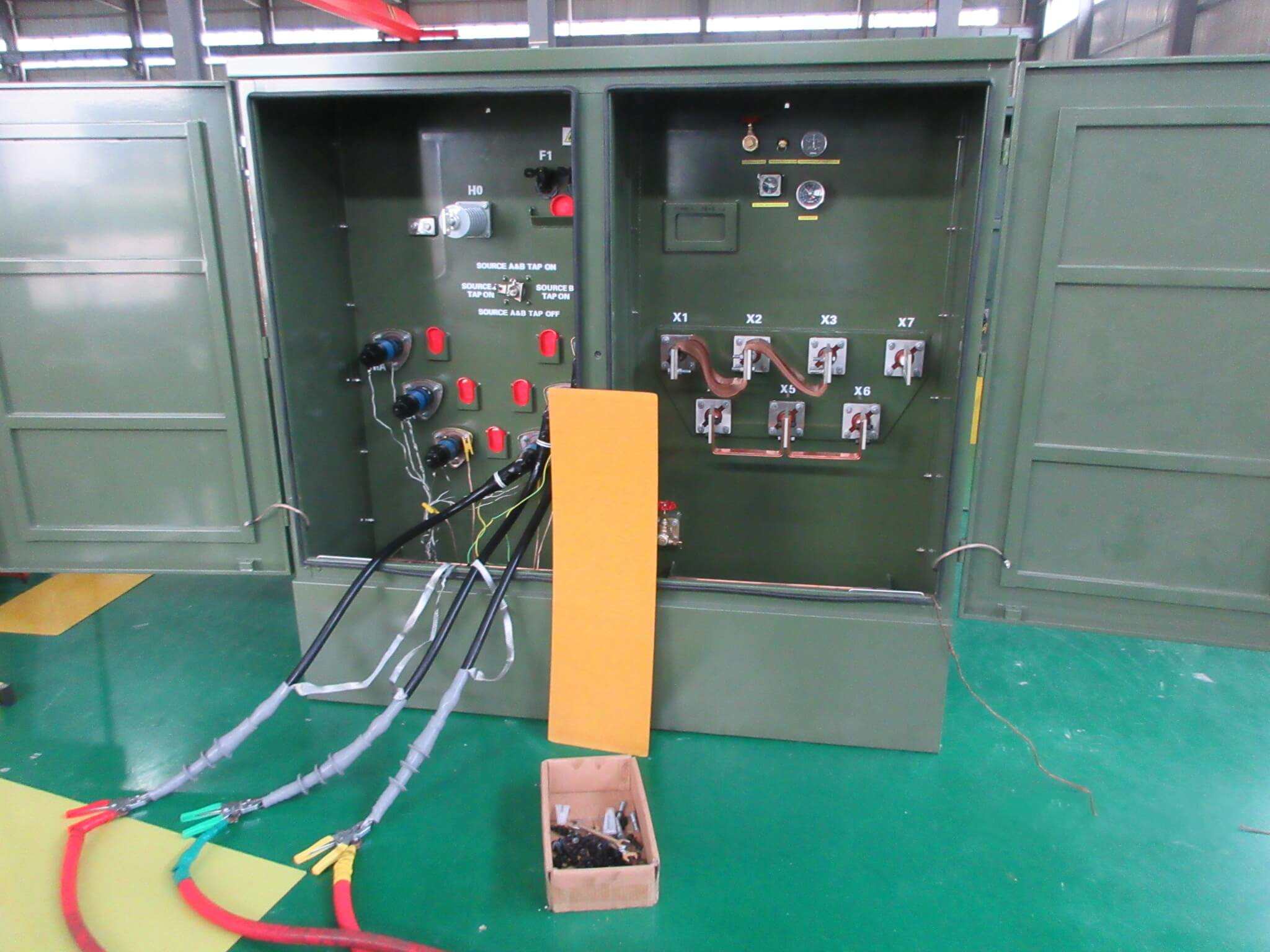

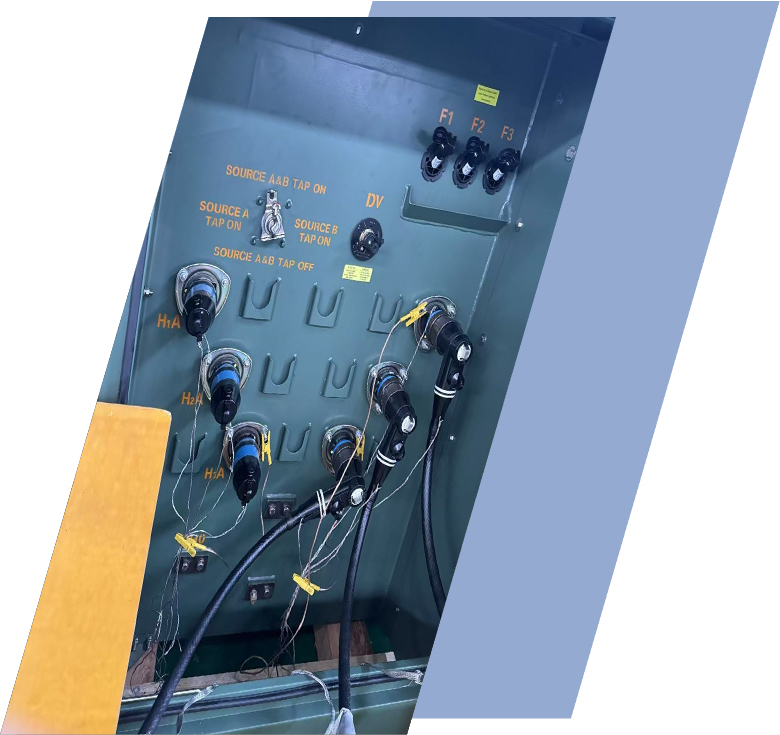

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

Packing and Shipping

To ensure comprehensive protection, the transformer is enveloped in high-strength moisture-barrier plastic sheeting and sealed thoroughly. It is then enclosed in a custom-built export-grade wooden crate featuring reinforced corners, cross-bracing, and impact-absorbing materials. This design complies with ISPM-15 fumigation standards for global shipping, preventing pest-related issues. Temporary anti-corrosion coatings are applied to exposed metal surfaces, while desiccant packs and humidity indicator cards monitor internal conditions throughout transit, reducing risks from condensation or extreme weather.

Shipping is managed through reliable partners offering multiple modes: full container load (FCL) sea freight in 40ft high-cube containers for international deliveries, flatbed trucking for domestic or regional hauls, or specialized heavy-lift services for oversized transport. Full tracking, marine insurance, and complete export documentation—including commercial invoices, detailed packing lists, certificates of origin, and certified test reports—are provided to facilitate smooth customs clearance. Standard lead times range from 2-4 weeks for in-stock models to 6-10 weeks for fully customized units, with expedited options available.

Upon delivery, professional unloading is recommended using the built-in lifting lugs and spreader bars, followed by immediate visual inspection for transit damage. The secure packaging ensures the transformer arrives installation-ready on a prepared concrete pad, preserving the full manufacturer's warranty and minimizing site preparation time or additional costs.

Manufacturer Test

Progress test

Throughout core assembly, rigorous checks verify lamination stacking for precise alignment, minimal burrs, and secure clamping to reduce core losses and noise. Winding fabrication includes precise turn counting, uniform insulation application (using thermally upgraded paper), conductor tension control, and layer-by-layer inspection to avoid shorts or deformations. Vacuum drying and oil impregnation processes are monitored to achieve a moisture content below 0.5% and full fluid penetration. Preliminary electrical measurements, such as DC winding resistance, turns ratio, and polarity/vector group, are performed on each phase to confirm balance (<1.5% deviation) and adherence to design specifications before core-coil assembly advances to tanking.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Comprehensive impulse testing (full-wave BIL) confirms lightning surge resistance, while partial discharge analysis ensures insulation quality (<5 pC at test voltage). Functional verification includes smooth tap changer operation with position indication, pressure relief valve activation, accurate liquid level/pressure/vacuum gauges, and accessory performance (drain/sampling valves). Final leak testing under pressure verifies sealing integrity, supplemented by post-filling oil dielectric strength, moisture content, and dissolved gas analysis (DGA). A detailed certified test report documents all results, confirming the 630kVA pad mounted transformer meets contractual specifications and standards prior to shipment.

Routine Test - Transformer Turns Ratio/TTR (All Tap Voltages)

Voltage source: usually AC 10 V to 30 V , used to test different voltages for each tap.

Temperature and humidity meter: used to record environmental conditions during the test to ensure test accuracy.

Current probe: used to measure the load current of the winding and ensure the accuracy of the test results.

Perform the test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C). Avoid high humidity or bad weather that may affect the test accuracy.

The voltage ratio between the windings

Deviation of the measured value from the rated ratio

0.5% < Turns ratio error ≤ 1% (caution)

Turns ratio error > 1% (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.