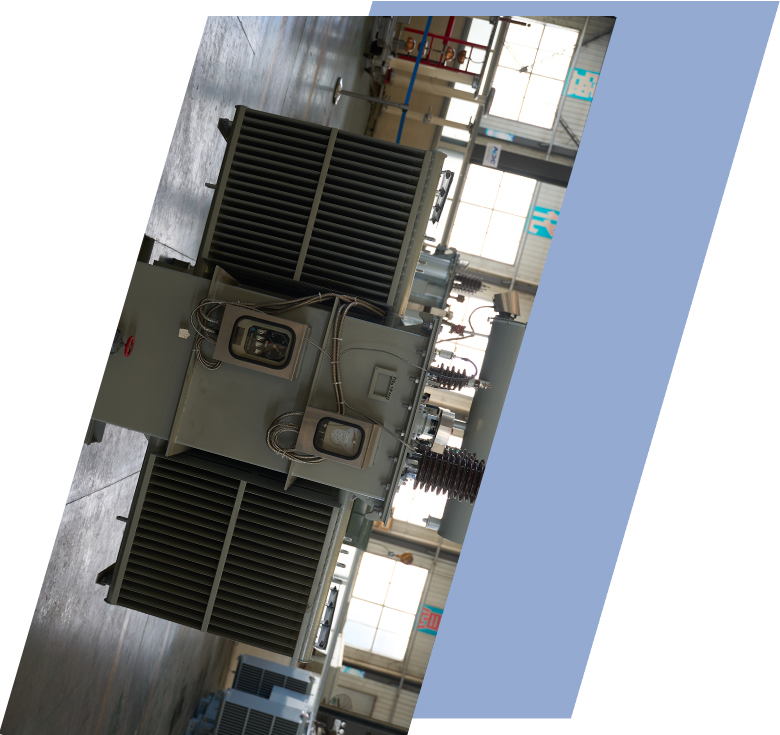

37kV 10000kVA(10MVA) Three Phase Duplex Winding Oil Immersed Power Transformer

- Primary Voltage Ratings 35kV, 34.5kV, 33kV, 46kV or others

- Secondary Voltage Ratings 13.8kV 6kV 10kV or others

- H.V. Tap Range ±8×1.25% or others

- Type Oil-immersed power transformer

- BIL 37kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application industrial substations, steel & cement plants, oil refineries, mining operations

- Power Rating 10000kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN/ONAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 10000kVA | |

| Rating Primary Voltage | 37 kV | |

| Secondary Voltage |

6.6kV 10kV 13.8kV Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

Packing and Shipping

All 37kV bushings, conservator, radiators, OLTC diverter, cooling fans, and instruments are dismantled and packed in separate IPPC-fumigated wooden crates with high-density foam and desiccant. The main tank (~45–52 tons) is welded onto a heavy-duty steel skid, fully enclosed in a reinforced marine-plywood crate with steel framing and double waterproof wrapping. Clear markings “37kV 10000kVA Three Phase Duplex Winding Oil Immersed Power Transformer”, lifting points, and shock indicators are applied.

Transport uses hydraulic modular trailers inland and DNV-certified 40ft flat-rack or break-bulk under-deck for sea freight, secured with Φ28 mm wire ropes and classification-society-approved lashing. Eight shock recorders monitor impact and tilt.

Full documentation (packing list, fumigation & origin certificates, nitrogen report, 110% insurance) accompanies every shipment, ensuring safe, damage-free global delivery and immediate site readiness.

Manufacturer Test

Progress Test

Throughout manufacturing, the 37kV 10MVA transformer undergoes rigorous, client-witnessable Progress Tests at every critical stage to ensure zero defects before final FAT.

Stage 1 – Core & Coil Assembly

- Winding DC resistance measurement on all taps (HV & LV duplex windings)

- Insulation resistance between HV-LV-core-tertiary and ground (PI ≥ 2.5 at 130 °C after drying)

- Core grounding current (<100 mA) and preliminary no-load loss verification

- Turns ratio check on random coils and magnetic balance test

Stage 2 – Before Tanking

- Voltage ratio at principal and extreme taps (deviation ≤ ±0.5 %)

- Vector group confirmation (typically Dyn11 or YNd11) and polarity

- Zero-sequence impedance and winding power frequency withstand pre-test

All raw data, charts and photographs are compiled into an official Progress Test Report and submitted for client or third-party approval before proceeding to Factory Acceptance Test, fully guaranteeing every 37kV 10000kVA transformer meets the highest quality and reliability standards.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Conducted per IEC 60076 with full client/third-party witness: winding resistance at all taps, ratio & polarity at extreme taps (≤ ±0.5%), vector group Dyn11/YNd11, no-load loss/current at 90–110% voltage, load loss & impedance at 75 °C, separate-source & induced withstand with PD <10 pC, lightning impulse 170–200 kV peak, insulation resistance/PI (≥ 2.5)/tanδ, oil test ≥ 70 kV, OLTC 10 full-load + 50 auxiliary cycles, cooling & protection function, sound level, final inspection. Signed protocol guarantees 100% readiness.

Routine Test - No Load Loss Test

Voltage source (usually 230V, 400V or customized according to customer requirements to adapt to different equipment)

Power analyzer (used to measure power loss and efficiency)

Ammeter and voltmeter

Temperature and humidity meter

Please ensure that the test is carried out in a suitable environment with a relative humidity of less than 75% and avoid rainy days or extreme weather (recommended temperature range: 20-30°C).

Connect the test equipment to the high voltage side of the transformer, making sure the wiring is correct and the equipment is grounded.

Apply Test Voltage:

Usually it is 110% of the rated voltage, for example, if the rated voltage of the transformer is 33 KV, apply 36.3 KV (110%).

No Load Current

No Load Loss

Power Factor

Current

Voltage

Temperature and Humidity

No-load loss < 0.2% ≤ 0.5% rated power (good)

No-load loss > 0.5% rated power (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.