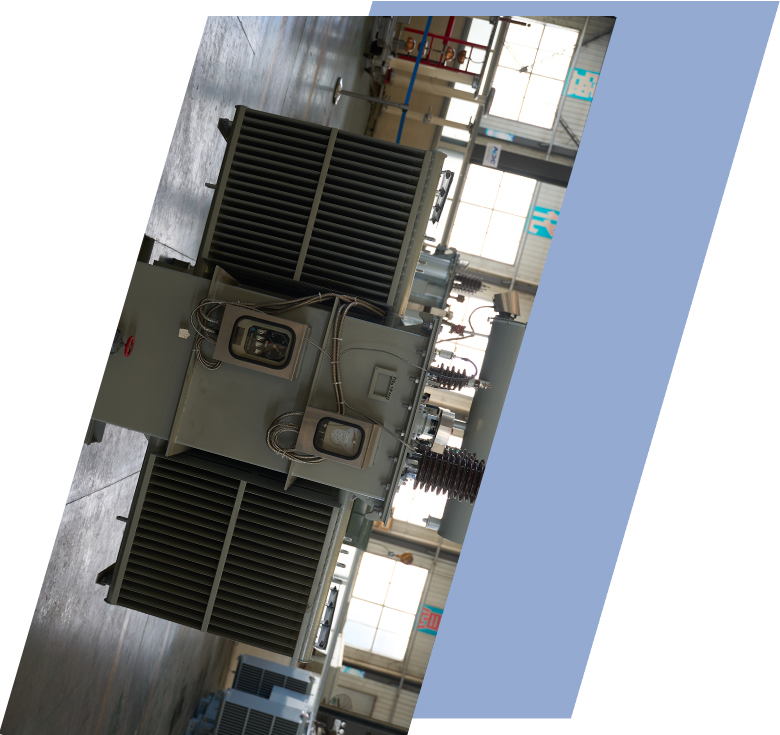

5MVA / 6.3MVA 35kV Three-Phase Oil-Immersed Step-Down Power Transformer

- Primary Voltage Ratings 35kV, 34.5kV, 33kV, 46kV or others

- Secondary Voltage Ratings 13.8kV 6kV 10kV or others

- H.V. Tap Range ±8×1.25% or others

- Type Oil-immersed power transformer

- BIL 35kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application utility substations, industrial power plants, mining sites, renewable energy stations

- Power Rating 5MVA - 6.3MVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN/ONAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 5MVA - 6.3MVA | |

| Rating Primary Voltage | 35 kV | |

| Secondary Voltage |

6.6kV 10kV 13.8kV Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

Packing and Shipping

The main transformer body is fixed to a heavy-duty steel or wooden pallet using industrial-grade bolts, steel straps, and anti-slip blocks. Vibration-damping pads, corner protectors, and steel framing are added depending on the unit’s size and weight. A complete set of documentation—including test reports, operation manuals, nameplate data, and packing lists—is stored in a waterproof envelope attached securely to the transformer.

Transport options include sea freight, land trucking, and rail transport. The transformer can be shipped using flat racks, open-top containers, or specialized heavy-load equipment depending on dimensions. Lifting lugs and forklift channels are clearly marked for safe loading and unloading. All logistics processes comply with IEC, ISO, and export regulations, ensuring the 35kV step-down transformer arrives at its destination safely and ready for installation.

Manufacturer Test

Progress Test

During manufacturing, the 5MVA / 6.3MVA 35kV Three-Phase Oil-Immersed Step-Down Power Transformer undergoes continuous Progress Testing to verify each production stage. Inspections include material quality checks, core lamination accuracy, winding tension and alignment verification, and insulation evaluation. Intermediate electrical tests—such as DC resistance measurement, turns ratio verification, insulation resistance, and partial discharge testing—identify early deviations. Mechanical inspections ensure tank strength, structural integrity, and assembly precision. Oil processing tests confirm moisture removal and dielectric strength. This step-by-step testing system ensures product consistency, reliability, and compliance prior to final assembly and acceptance testing.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Before delivery, the 5MVA / 6.3MVA 35kV Three-Phase Oil-Immersed Step-Down Power Transformer undergoes a full Factory Acceptance Test (FAT) following IEC 60076 standards. Key tests include winding resistance measurement, voltage ratio and vector group verification, no-load and load loss measurement, insulation resistance evaluation, induced overvoltage test, and applied high-voltage withstand test. Partial discharge and dielectric tests confirm insulation strength. Mechanical inspections validate tank pressure performance, protection devices, and accessory functionality. Oil quality analysis, terminal checks, and safety device calibration ensure operational readiness. The FAT guarantees that the transformer meets performance, safety, and customer specifications before shipment.

Routine Test - Insulation Power Factor

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.