3000kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, CSA

- Application EV charging, BESS, Data center, Industry, Renewable energy

- Power Rating 3000kVA

- Certificate UL, CUL, CSA, SGS

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 3000 kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 2400 kg |

| Total Weight | 7000 kg |

| Outline Dimensions(L×W×H)in. | 2400×2600×2400(mm) |

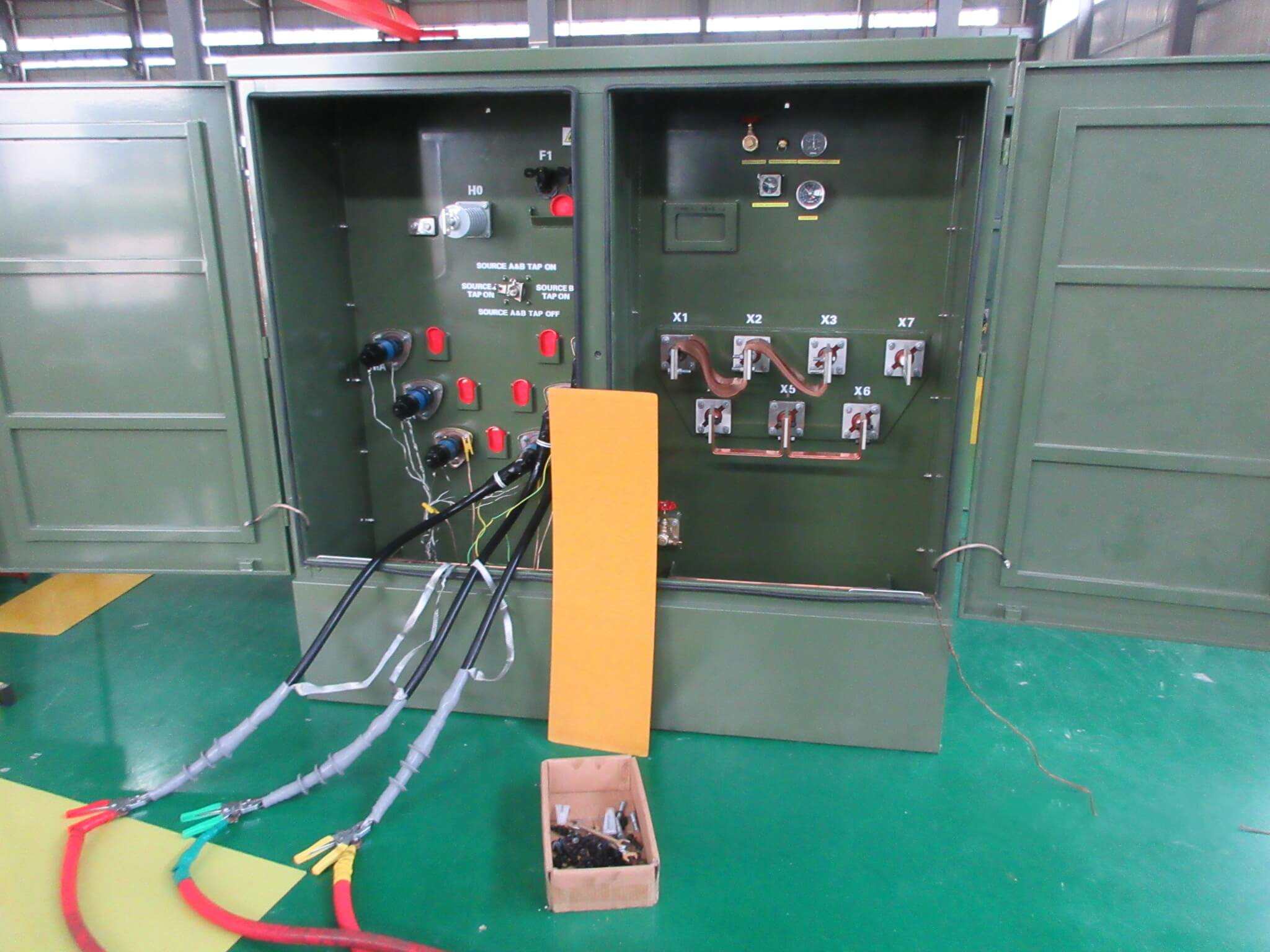

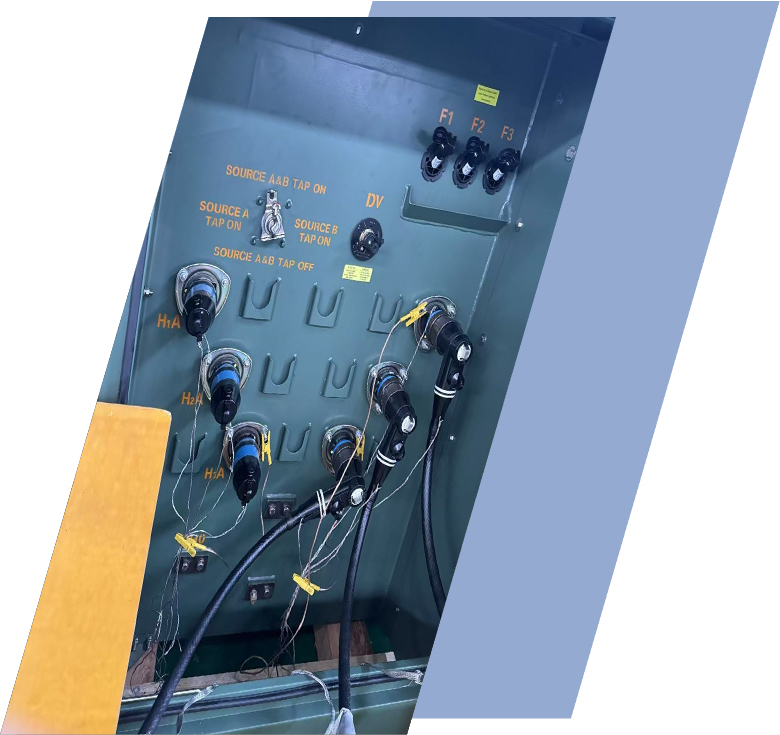

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

Packing and Shipping

Transformers are usually fixed with sturdy steel frames or wooden boxes, and anti-vibration pads are used to reduce shock during transportation. All exposed metal parts are treated to prevent rust and are additionally protected with moisture-proof membranes or sealed covers to prevent salt spray and moisture corrosion. Sensitive parts (such as terminals, oil level gauges, and pressure relief valves) are reinforced with additional protective covers or filling materials to avoid damage.

Small or medium-sized transformers can be transported in standard containers and reinforced to ensure stability. Larger transformers are usually transported in frame or open-top containers and reinforced with steel cables and fixed brackets to prevent displacement. The center of gravity is calculated before transportation to ensure that the center of gravity is balanced during loading and unloading to avoid tilting or damage. After the transformer arrives at the port, it will be hoisted by professional equipment and stored or transported to the final destination in a specified manner.

The entire packaging and transportation process is carried out in accordance with international shipping standards to ensure the safety and reliability of the transformer during long-distance transportation, avoid damage caused by external environmental factors, and thus ensure the final delivery quality of the product.

Upon delivery, detailed installation guides cover lifting (via designated lugs), foundation alignment, oil replenishment if required, and initial energization checks. Optional origin witness inspections or third-party surveys can be arranged. Our dedicated logistics coordination ensures minimal delays, regulatory compliance, and transformer integrity from factory floor to final site.

Manufacturer Test

Progress test

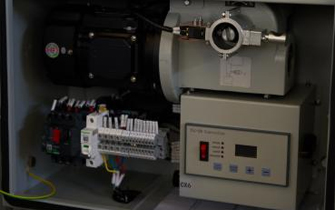

NPC Electric's 3000kVA Three Phase Pad Mounted transformer factory production process testing includes but is not limited to quality inspection of key components such as coils, cores, and insulation materials; testing the insulation system of the transformer; measuring the no-load loss, load loss, and short-circuit impedance of the transformer; and conducting power frequency withstand voltage and impulse withstand voltage tests on the transformer. Through these tests, it can be ensured that the transformer reaches the best performance standards before leaving the factory, complies with industry specifications, and operates safely and stably in various application environments. Oil processing tracks dehydration, filtration cycles, and dielectric sampling to reach <10ppm moisture and >60kV breakdown strength. Pre-paint inspections assess enclosure dimensions, grounding continuity, and hardware torque. These incremental validations enable early defect identification, ensuring final product meets efficiency, impedance, and durability benchmarks seamlessly.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The 3000kVA Three Phase Pad Mounted transformer factory acceptance test (Transformer Factory Acceptance Test, FAT) is a key step to ensure that the transformer meets the design standards and customer requirements before delivery. Induced potential test doubles frequency to evaluate turn-to-turn and layer insulation integrity under overvoltage stress with partial discharge monitoring. No-load loss and magnetizing current determination at rated voltage validates core efficiency against DOE levels. Impedance and load loss testing at rated current quantifies percentage impedance, copper losses, and X/R ratio for coordination studies. Oil quality analysis includes dielectric breakdown, moisture, acidity, and dissipation factor per ASTM to verify fluid suitability. Operational verification cycles load-break switches, tap changers, fuses, relief devices, and alarms for functionality. Optional witnessed tests may encompass sound power level, temperature rise heat run, or special impulse if specified. Certified reports with calibration traceability and customer witness provisions (if requested) document all parameters, affirming the transformer's readiness for efficient, safe installation and superior service life.

Routine Test - Leak Test

Voltage source (usually 500V, 1 KV or 2.5 KV, customized according to test requirements)

Temperature and humidity meter

Ground electrode

Properly connect the test equipment (such as a leak detector) to the pipe, container or sealing structure of the device under test.

Apply Test Voltage:

Apply the appropriate test pressure (e.g. 10 bar, 15 bar, etc.) depending on the equipment's operating pressure or test standard.

Applied test pressure

Leakage (can be monitored by flow meter or other equipment)

Time record (to ensure that the test time meets the standard requirements)

Initial pressure and final pressure (if any changes)

Minor leakage (good): Very small leakage is allowed, and it is necessary to judge whether it is qualified according to industry standards.

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.