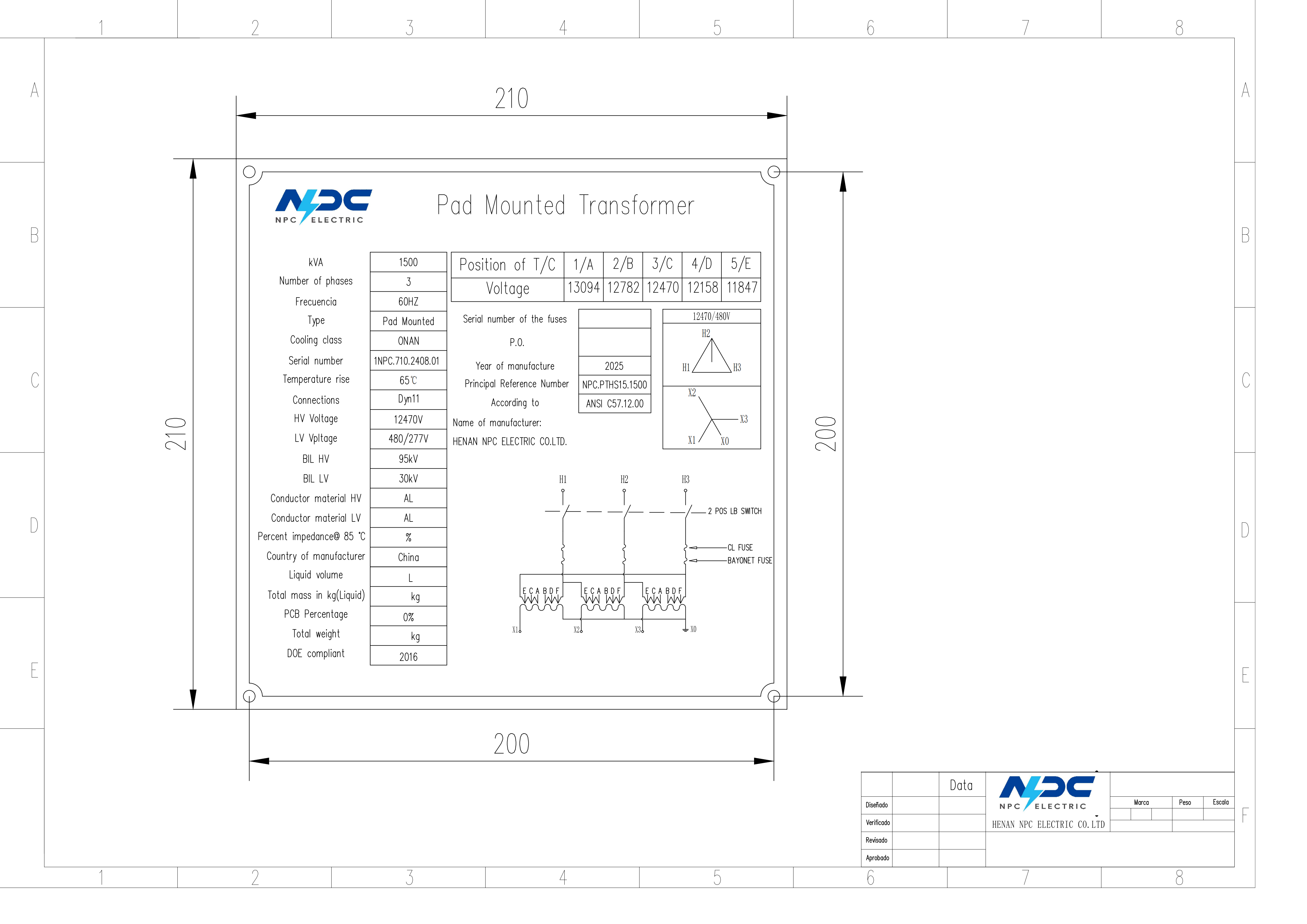

1500kVA Radial Feed Pad Mounted transformer DOE 2016

- Primary Voltage Ratings 12470 V

- Secondary Voltage Ratings 480/277 V

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Radial Feed

- BIL 95/30 kV

- Standards IEEE C57.12.34/C57.12.24/C57.12.0

- Application Solar Project

- Power Rating 1500kVA

- Certificate UL

- Cooling Method ONAN

- Oil Mineral Oil

- Opeartion Step Down

Technical Specifications

| Rated Power | 1500 kVA |

| Rating Primary Voltage | 12470V Delta |

| Secondary Voltage | 480GrdY/277 |

| Frequency | 60Hz |

| Vector Group | Dyn11 |

| Winding Material | Aluminum |

| Efficiency | Doe 2016 |

| Impedance Voltage | 5.75% |

| Altitude | 1200 m |

| Color | Munsell 7GY3.29 |

| Tank material | Mild Steel |

| Insulating Oil Weight | 1500 kg |

| Total Weight | 5650 kg |

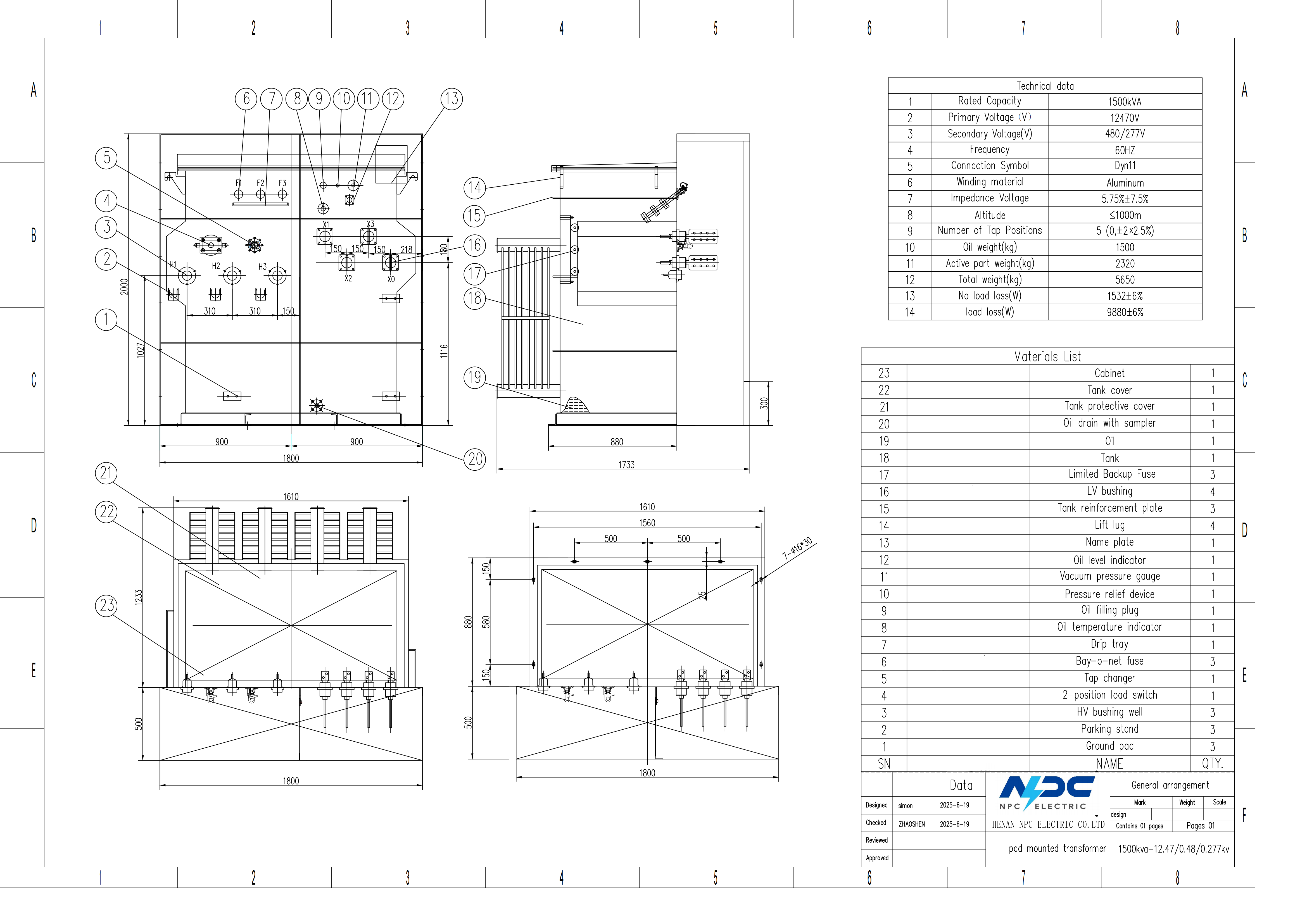

| Outline Dimensions(L×W×H)in. | 1733×1800×2000(mm) |

| Lifting Lug | ELSP Fuse |

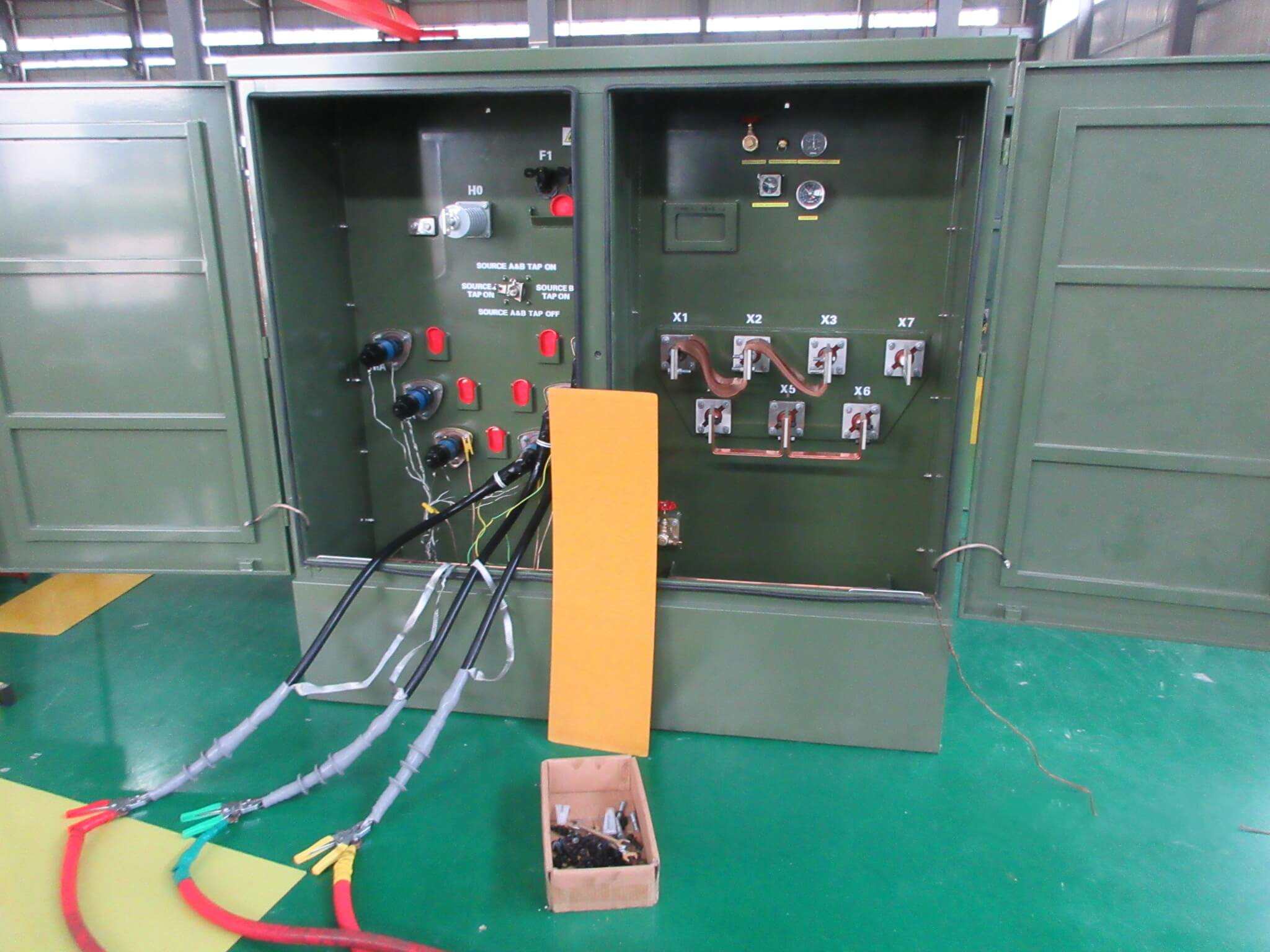

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

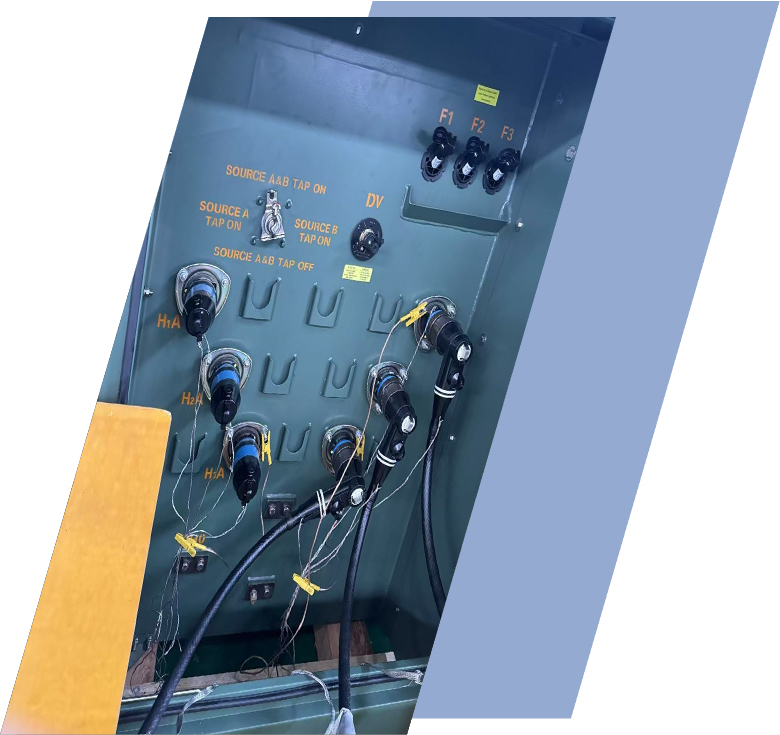

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | - |

| Non-PCB decal | - |

Customization Optional

The transformer supports two cooling methods: ONAN (natural oil cooling) and ONAF (forced air cooling). Users can choose according to load continuity and ambient temperature requirements. For high temperature or continuous heavy load scenarios, it is recommended to select ONAF to improve cooling efficiency.

The high and low voltage sides support elbow joints (200A/600A), bolted connections and busbar interfaces. Withdrawable fuses and cable branch boxes are also available for easy installation and maintenance. All interfaces comply with ANSI/IEEE standards to ensure compatibility and reliability.

The standard housing is made of hot-dip galvanized steel, and stainless steel can also be used to adapt to humid or corrosive environments. The protection level is NEMA 3R by default, and customers can upgrade to NEMA 4 or IP54 protection levels. The surface color of the housing can also be customized according to customer requirements.

With these flexible options, we ensure that our transformers can be customized for specific applications, environments, and safety standards, offering long-term reliability and performance.

Packing and Shipping

The unit is secured on a reinforced wooden pallet or skid base for forklift/crane handling, wrapped in volatile corrosion inhibitor (VCI) paper, heavy polyethylene sheeting, and fastened with steel banding. Desiccant bags control humidity. Oil ships fully filled with nitrogen blanketing for positive pressure or partially filled with separate sealed drums to meet hazmat rules and reduce weight (typical filled weight 8000–11000 kg / 17600–24200 lbs).

Export crating complies with ISPM-15 heat-treated lumber standards, reinforced with steel strapping, corner protectors, and clear markings for weight, center of gravity, lift points (tank lugs), dimensions (approx. 3.6–4.2m L × 3.3–3.7m W × 3.4–4.0m H), and handling instructions ("High Voltage Equipment – Handle with Care"). Tamper-evident seals secure access; weatherproof covers protect HV/LV bushings and compartments. Domestic transport uses flatbed/lowboy trailers with secure blocking/strapping; oversize permits arranged if needed. International shipments (including to Honduras or Latin America) feature 40ft open-top containers or flat-rack loading, with professional lashing using chains, binders, and timber dunnage for sea/road stability. Real-time GPS tracking and full-value cargo insurance provide protection.

Delivery includes handling/installation instructions: safe lifting via tank lugs, foundation alignment, oil level check/top-off (if partial), grounding, bushing connections, and initial energization procedures. Customs documentation (commercial invoice, packing list, certificate of origin, test reports, efficiency certifications) expedites clearance. Optional origin witness inspections or third-party surveys available. Logistics team coordinates for minimal delays, full regulatory compliance, and transformer arrival in optimal condition for quick installation.

Manufacturer Test

Progress test

Progress tests for the 1500kVA radial feed pad mounted transformer are conducted at critical manufacturing stages to ensure material quality, dimensional accuracy, and electrical performance early. Core lamination stacking is inspected for precise alignment, clamp torque, and inter-lamination insulation to achieve low no-load losses and minimal hum. Winding checks confirm turn counts via automated systems, conductor tension uniformity, insulation layering, and transposition for balanced impedance/thermal profile. Post-core-coil assembly, preliminary resistance, turns ratio, polarity, and inductance tests validate symmetry, correct phasing, and defect-free windings. Enclosure progress includes weld nondestructive testing, dimensional conformance, and surface preparation for coating adhesion. Ventilation/encapsulation assesses flow consistency or potting quality.These sequential validations enable prompt corrections, aligning with DOE 2016 efficiency goals, impedance specs, and insulation class standards.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The factory acceptance test (FAT) of the 1500kVA Radial Feed Pad Mounted transformer DOE 2016 is a series of tests conducted before the transformer leaves the factory to ensure that the product meets the design and quality requirements. Factory acceptance tests (FAT) for the 1500kVA radial feed pad mounted transformer adhere to IEEE C57.12.01, C57.12.90, and DOE protocols to confirm performance pre-shipment. Routine visual/mechanical inspections examine enclosure finish, welds, nameplate data, connections, taps, and grounding. Winding resistance across taps at temperature-corrected values verifies uniformity and design match. Turns ratio (TTR) on all positions ensures accuracy within 0.5% and proper vector group. Polarity checks align with specifications. Insulation resistance (megger at 1000–2500V) assesses winding-to-winding/ground for high megohm integrity. Applied potential withstand applies one-minute power-frequency voltage per class without breakdown/corona.

Routine Test - Winding Resistance

Test voltage source (commonly used are 6V, 10V, 20V, 40V or 100V, depending on the equipment model or customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test)

Disconnect the electrical connection between the test cable and the equipment to ensure that there is no external current or voltage interference.

Select a suitable voltage range for testing and set the test voltage according to the equipment requirements.

Connect the test equipment to the winding terminals of the device under test, making sure the connections are secure and properly grounded to avoid measurement errors.

Apply Test Voltage:

Select the appropriate test current according to the equipment specifications (such as test current for low-voltage windings, single-phase or three-phase windings).

Winding resistance (usually expressed in units of "Ω")

Test current (A)

Test voltage (V)

Temperature (record the winding temperature before and after the test)

Resistance deviation is between 5% and 10% (warning)

Resistance deviation exceeds 10% (further inspection or corrective action is required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.