11kV Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed distribution transformer

- BIL 11kV

- Standards IEEE, ANSI, NEMA, IEC, CE

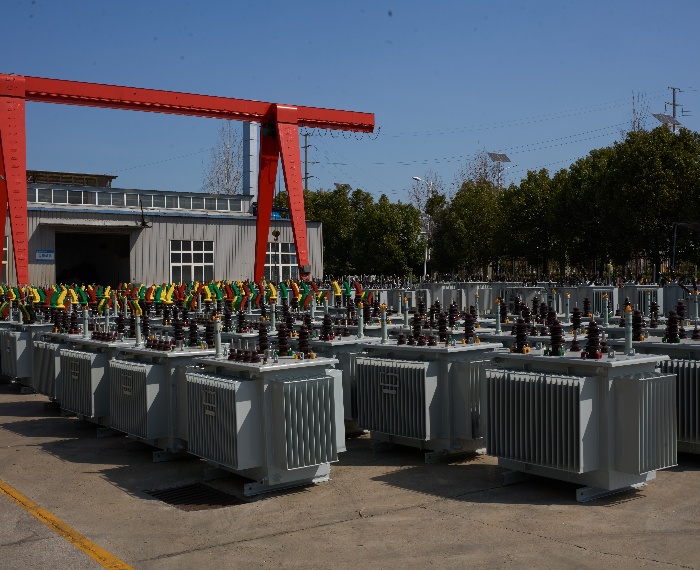

- Application commercial building complexes, modern agricultural power facilities

- Power Rating 30kVA - 5000kVA

- Certificate UL, CESI, IEEE

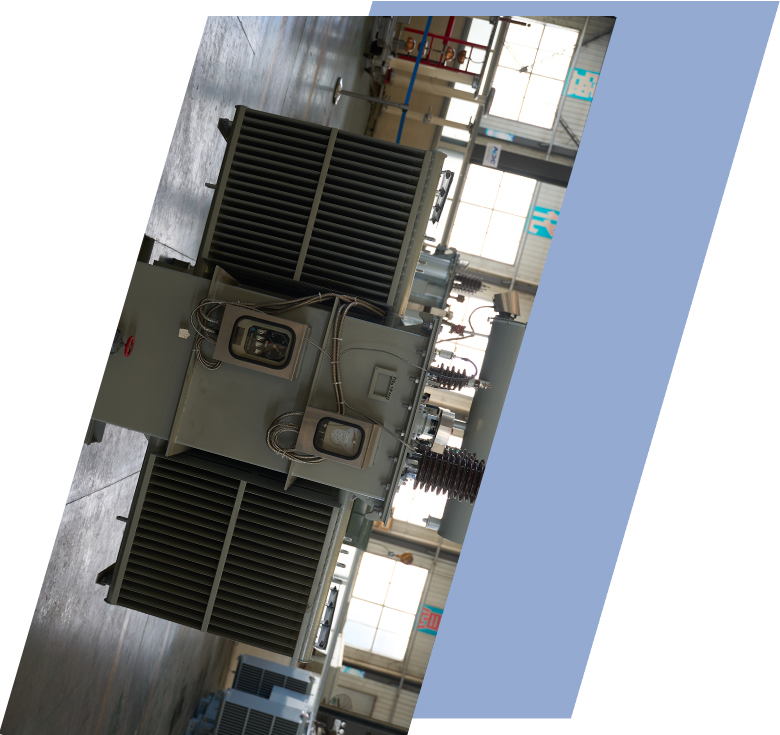

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 30kVA - 5000kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 850 kg | |

| Total Weight | 5000 kg | |

| Outline Dimensions(L×W×H)in. | 2650 × 1650 × 2450(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

Packing and Shipping

Individual components receive dedicated protection: bushings wrapped in foam and crated separately, radiators shielded with corrugated covers, control boxes padded and sealed against dust/moisture, and accessories like tap changers locked in position. Full-unit packaging utilizes heavy-duty wooden cases or steel skid bases meeting ISPM-15 phytosanitary requirements, reinforced with internal bracing, impact-absorbing cushions, and anti-vibration mounts to endure road, rail, and sea transport stresses. Moisture barriers, silica gel desiccants, corrosion-preventive coatings, and humidity/temperature indicators are standard inclusions, alongside shock/tilt recorders for monitoring handling.

For international ocean freight—the primary mode for export—transformers are loaded onto flat-rack or open-top containers, or secured via RoRo vessels, with protective tarpaulins, salt-resistant wraps, and lashing compliant to IMO standards. Overland transport employs low-bed trailers with specialized cradles for weight distribution and secure tie-downs. Comprehensive export documentation includes detailed packing lists, commercial invoices, certificates of conformity, routine/test reports, dimensional drawings, handling instructions, and customs declarations (HS codes, origin certificates, oil safety data sheets).

We provide end-to-end logistics coordination, including port-to-site delivery options, customs brokerage support, and optional on-site services such as professional unloading supervision, oil reclamation/filtering, erection guidance, and commissioning tests. This thorough process safeguards against transit damage, maintains factory-fresh condition, ensures regulatory compliance, and supports reliable, on-schedule arrival for global customers.

Manufacturer Test

Progress Test

Progress testing in 11kV oil immersed transformer production starts with incoming material verification for silicon steel sheets checking lamination thickness coating quality and magnetic properties via Epstein frame samples to guarantee low core losses. Core building progress test inspects precise step-lap miter joints clamping force uniformity and no-burr assembly to avoid increased eddy currents or mechanical hum. Winding process monitoring includes conductor resistivity tension uniformity insulation wrapping thickness and inter-turn spacing measured with high-precision tools for dielectric reliability. After coil-core integration progress test confirms adequate clearance distances axial compression stability and secure bracing to resist electromagnetic forces. Tank manufacturing progress test evaluates weld seam continuity pressure integrity surface preparation and painting thickness for long-term corrosion resistance. Pre-final assembly progress test verifies component alignment accessory mounting bushings radiators conservator (if used) and preliminary vacuum/pressure simulation to identify early defects ensuring smooth advancement to comprehensive testing stages.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory Acceptance Test (FAT) for 11kV oil immersed transformer initiates with routine insulation resistance and polarization index measurements to assess winding dryness and contamination levels per IEC 60076 guidelines. Separate-source withstand voltage and induced voltage tests apply elevated potentials to validate major insulation strength between windings core and ground. Winding resistance DC testing at controlled temperature determines conductor integrity calculates temperature-corrected values and detects connection issues. Voltage ratio turn ratio and phase angle verification using automated testers confirms accurate ratios vector group adherence (e.g. Dyn11) and correct polarity across all taps. No-load loss and exciting current measurement at rated voltage evaluates core efficiency harmonic content and magnetization performance ensuring compliance with specified low no-load levels.

Routine Test - Winding Resistance

Test voltage source (commonly used are 6V, 10V, 20V, 40V or 100V, depending on the equipment model or customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test)

Disconnect the electrical connection between the test cable and the equipment to ensure that there is no external current or voltage interference.

Select a suitable voltage range for testing and set the test voltage according to the equipment requirements.

Connect the test equipment to the winding terminals of the device under test, making sure the connections are secure and properly grounded to avoid measurement errors.

Apply Test Voltage:

Select the appropriate test current according to the equipment specifications (such as test current for low-voltage windings, single-phase or three-phase windings).

Winding resistance (usually expressed in units of "Ω")

Test current (A)

Test voltage (V)

Temperature (record the winding temperature before and after the test)

Resistance deviation is between 5% and 10% (warning)

Resistance deviation exceeds 10% (further inspection or corrective action is required)

Application

Technical Advantages

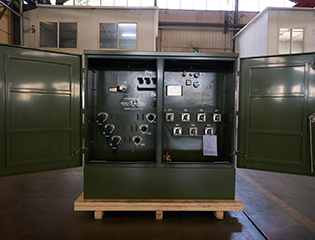

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.