Wires and Cables

Wires and Cables

477 MCM HAWK ACSR Conductor Cable

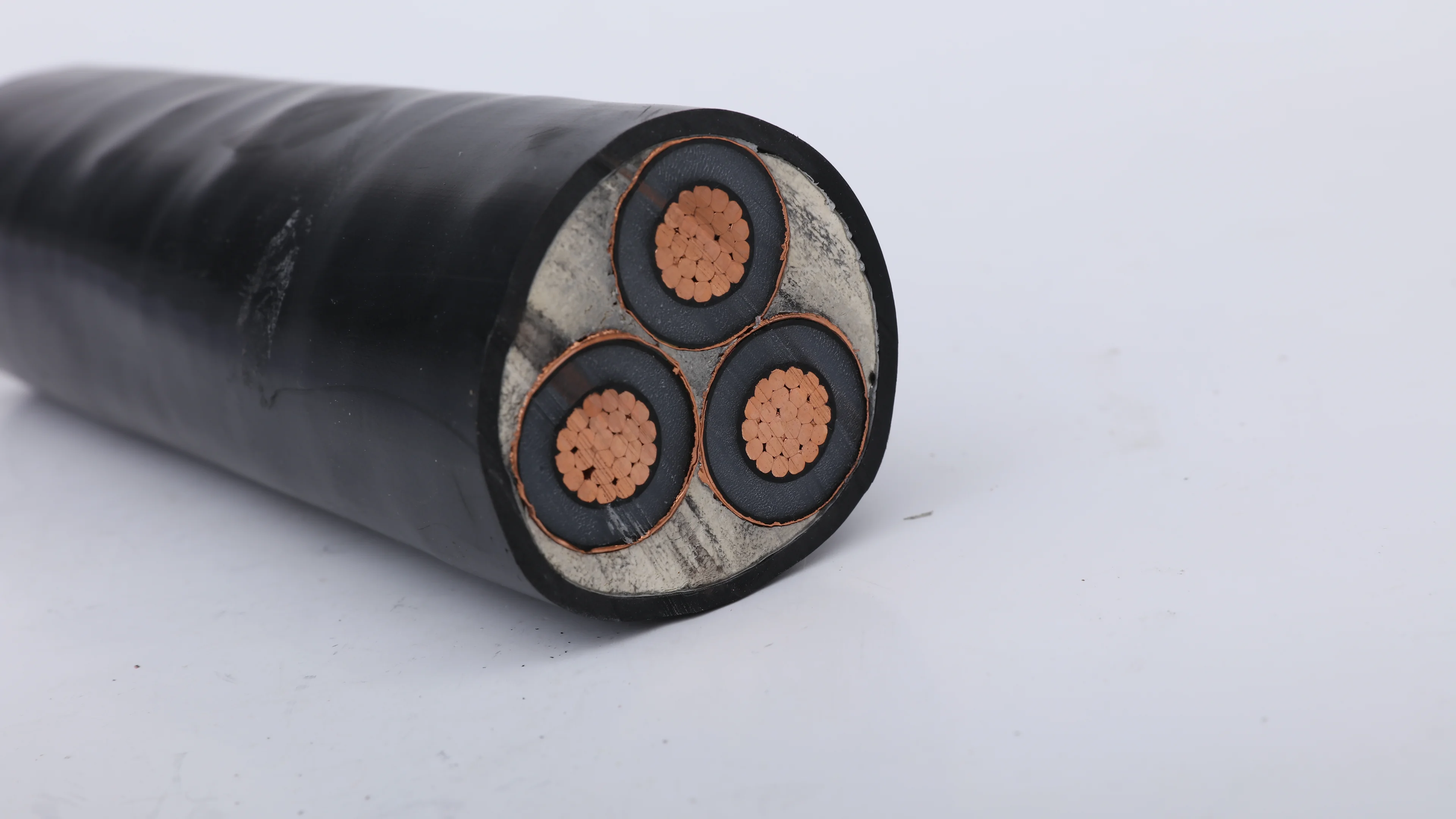

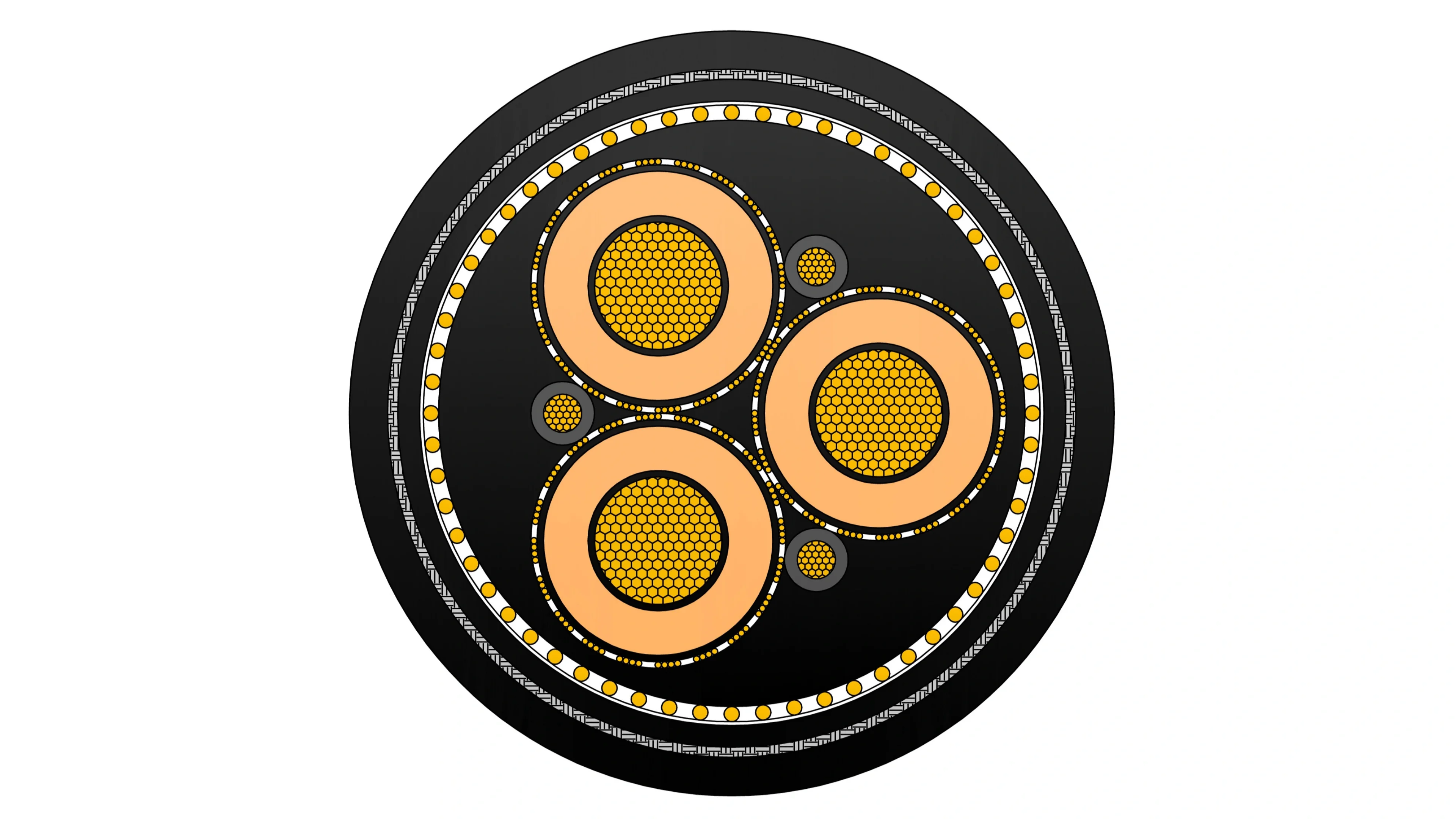

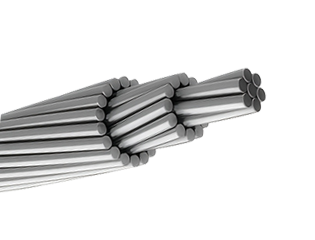

The 477 MCM HAWK ACSR Conductor Cable is a robust and highly efficient Aluminium Conductor Steel Reinforced (ACSR) cable engineered for overhead transmission and distribution networks. It consists of 26 hard-drawn 1350-H19 aluminium wires concentrically stranded around 7 galvanized steel wires, delivering an optimal blend of electrical conductivity and mechanical strength. Designed and manufactured in accordance with ASTM B232, the HAWK configuration is well-suited for long-span overhead lines, where elevated tensile performance is required to withstand environmental loads like wind and ice. The galvanized steel core, available in Class A or B, offers superior corrosion resistance, while the aluminium strands ensure high current-carrying capacity with low resistivity. This conductor is a popular choice in transmission infrastructure due to its balance of strength, weight, and performance, making it a cost-effective and reliable solution in a wide range of operating environments.

477 MCM PELICAN ACSR Conductor Cable

The ACSR CAA 477 MCM 18/1F PELICAN conductor is a high-performance Aluminium Conductor Steel Reinforced (ACSR) cable designed for use in overhead transmission and distribution line systems. Constructed with 18 strands of hard-drawn 1350-H19 aluminium helically stranded around a single galvanized steel wire, this conductor offers a well-balanced combination of electrical conductivity, lightweight design, and mechanical strength. Manufactured in compliance with ASTM B232, the PELICAN configuration is ideal for long-span installations where tensile strength, corrosion resistance, and current-carrying capability are critical. The galvanized steel core, available with Class A or B galvanization, provides excellent protection against environmental degradation while reinforcing the aluminium layers with the mechanical support required for demanding utility applications. Its 18/1 stranded design makes the PELICAN conductor particularly suitable for medium- and high-voltage overhead systems where both performance and cost-efficiency are important.

556.5 MCM DOVE ACSR Conductor Cable

The ACSR CAA 556.5 MCM 26/7F DOVE is a high-capacity, steel-reinforced aluminium conductor designed for the efficient and reliable delivery of electrical power across overhead transmission and distribution lines. Its structure features 26 hard-drawn 1350-H19 aluminium strands wrapped around 7 galvanized steel strands, forming a strong, concentric-lay stranded design. Manufactured in accordance with ASTM B232, this conductor brings together the lightweight, conductive benefits of aluminium with the mechanical strength and durability of galvanized steel. The steel core, treated with Class A or B galvanization, offers essential corrosion protection, especially in harsh weather environments or long-span installations. The DOVE configuration is a popular industry standard for medium- to high-voltage overhead systems, offering excellent performance where long spans and high tension loads are involved. Its optimized aluminium-to-steel ratio makes it well-suited for utility transmission networks, helping reduce line losses while ensuring structural integrity.

556.5 MCM OSPREY ACSR Conductor Cable

The ACSR CAA 556.5 MCM 18/1F OSPREY conductor is a durable and efficient Aluminium Conductor Steel Reinforced (ACSR) cable, engineered to deliver consistent performance in overhead power transmission and distribution systems. With its construction of 18 hard-drawn 1350-H19 aluminium strands wrapped around a single galvanized steel wire, this conductor offers a dependable combination of lightweight conductivity and mechanical strength. Complying with ASTM B232 standards, the OSPREY conductor is ideal for medium- to long-span installations, particularly where increased mechanical support is necessary. The steel core, available with Class A or B galvanization, enhances corrosion resistance while supporting the conductor’s tensile integrity under challenging environmental and load conditions. Its 18/1F construction makes it particularly suited for projects where a balance of performance, durability, and cost-effectiveness is essential. It is widely used by utilities in transmission infrastructure, especially where moderate-to-high current capacity is required without compromising on mechanical reliability.

795 MCM DRAKE ACSR Conductor Cable

The ACSR CAA 795 MCM 26/7F DRAKE is a widely used, high-capacity overhead conductor designed for power transmission and distribution systems. It features a rugged construction of 26 hard-drawn 1350-H19 aluminium wires wrapped around 7 galvanized steel strands, forming a strong and conductive concentrically stranded cable. Built to ASTM B232 specifications, this conductor delivers excellent electrical performance, while its steel-reinforced core offers the mechanical strength needed for long-span installations. The steel strands are galvanized to Class A or B, providing reliable corrosion resistance in outdoor environments. With its proven design and high load-handling capabilities, the DRAKE configuration is commonly used across utility networks, particularly for high-voltage transmission lines where strength, conductivity, and longevity are critical. The aluminum 1350-H19 provides excellent corrosion resistance and low electrical resistance (0.0223 Ω/1000ft at 20°C), while the steel enhances sag control over long spans. Suitable for voltages up to 230kV in distribution lines, the 795 MCM Drake ACSR Conductor Cable minimizes line losses and withstands harsh weather, including wind and ice loading.

954 MCM CARDINAL ACSR Conductor Cable

The ACSR CAA 954 MCM 54/7F CARDINAL is a high-capacity, heavy-duty Aluminium Conductor Steel Reinforced (ACSR) cable engineered for the reliable transmission of electrical power over long-span overhead lines. It features 54 hard-drawn 1350-H19 aluminium strands concentrically laid around 7 galvanized steel strands, offering an optimized balance between excellent electrical conductivity and mechanical strength. Manufactured to meet the requirements of ASTM B232, the CARDINAL configuration is a trusted industry standard, widely adopted in high-voltage transmission systems. The galvanized steel core, available in Class A or B coatings, provides superior corrosion resistance and structural support, making this conductor ideal for outdoor environments exposed to wind, ice, and mechanical loading. The 54/7F strand design ensures increased current-carrying capacity and lower resistance, making it suitable for use in critical infrastructure and utility-grade transmission networks. Its cost-effective design makes it popular for utility upgrades and rural electrification, ensuring reliable power delivery with minimal maintenance in overhead transmission and distribution systems worldwide.

954 MCM RAIL ACSR Conductor Cable

The ACSR CAA 954 MCM 45/7F RAIL is a robust Aluminium Conductor Steel Reinforced (ACSR) cable designed to meet the demanding requirements of modern overhead transmission and distribution systems. It consists of 45 hard-drawn 1350-H19 aluminium strands concentrically wound around 7 galvanized steel strands, forming a high-capacity conductor with a reliable strength-to-conductivity ratio. Manufactured in accordance with ASTM B232, the RAIL configuration is ideal for long-span installations where increased tensile strength and environmental durability are essential. The galvanized steel core, coated to Class A or B standards, provides corrosion resistance and mechanical reinforcement against environmental stressors like wind, ice loading, and mechanical tension. This ACSR design supports efficient power delivery across overhead transmission networks, while also serving as a dependable solution for primary and secondary distribution lines. Suitable for voltages up to 230kV in distribution lines, the Rail ACSR Conductor Cable minimizes line losses and withstands harsh weather, including wind and ice loading.

1033.5 MCM CURLEW ACSR Conductor Cable

The ACSR 1033.5 MCM Curlew 54/7 is a high-performance, bare concentric-lay-stranded conductor designed for overhead power transmission and distribution lines. Complying with ASTM B232 standards, this conductor features a robust galvanized steel core (Class A or B) for enhanced mechanical strength, surrounded by multiple layers of hard-drawn 1350-H19 aluminum wire for superior electrical conductivity. The Curlew configuration, with 54 aluminum strands and 7 steel strands, ensures an optimal balance of durability and efficiency, making it ideal for long-span transmission lines and primary/secondary distribution networks. Engineered for reliability, ACSR Curlew offers excellent corrosion resistance and customizable aluminum-to-steel ratios to meet specific electrical and mechanical requirements.

1033.5 MCM ORTOLAN ACSR Conductor Cable

The Ortolan ACSR Conductor Cable is a high-capacity overhead conductor designed for efficient power transmission. Named "Ortolan" for its 1033.5 MCM size with 45/7 stranding (45 aluminum wires around 7 steel cores), it combines lightweight aluminum for conductivity with a galvanized steel core for tensile strength. Compliant with ASTM B230, B232, and ICEA standards, this cable offers a breaking load of approximately 32,300 lbs and a current rating up to 1000 amps at 75°C in overhead applications. The aluminum 1350-H19 provides excellent corrosion resistance and low electrical resistance (0.0166 Ω/1000ft at 20°C), while the steel enhances sag control over long spans. Suitable for voltages up to 230kV in distribution lines, the Ortolan ACSR Conductor Cable minimizes line losses and withstands harsh weather, including wind and ice loading. Its cost-effective design makes it popular for utility upgrades and rural electrification, ensuring reliable power delivery with minimal maintenance in overhead transmission and distribution systems worldwide.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, NPC wires and cables exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

NPC wires and cables have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

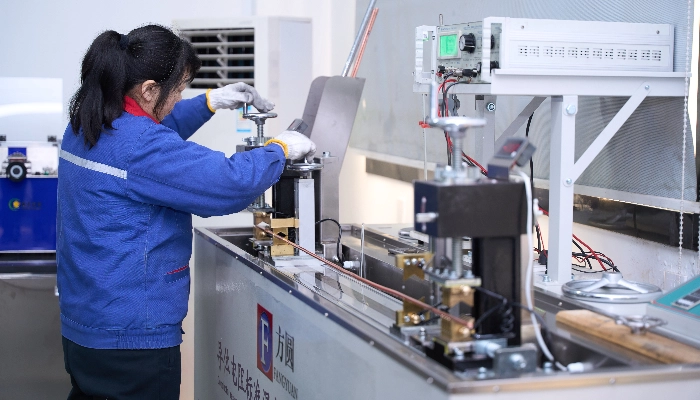

Wires & Cables Manufacturer

Wires & Cables Products

Wires & Cables Testing

Efficient Logistics & Timely Delivery

Testing and Certification

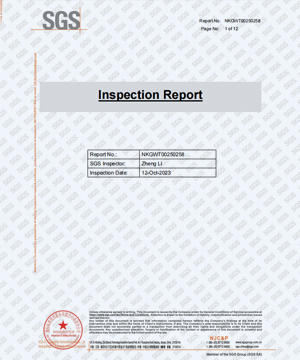

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

ISO Environmental Certificate

ISO Occupational Certificate

UL Laboratory Certificate

UL Product Certificate

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

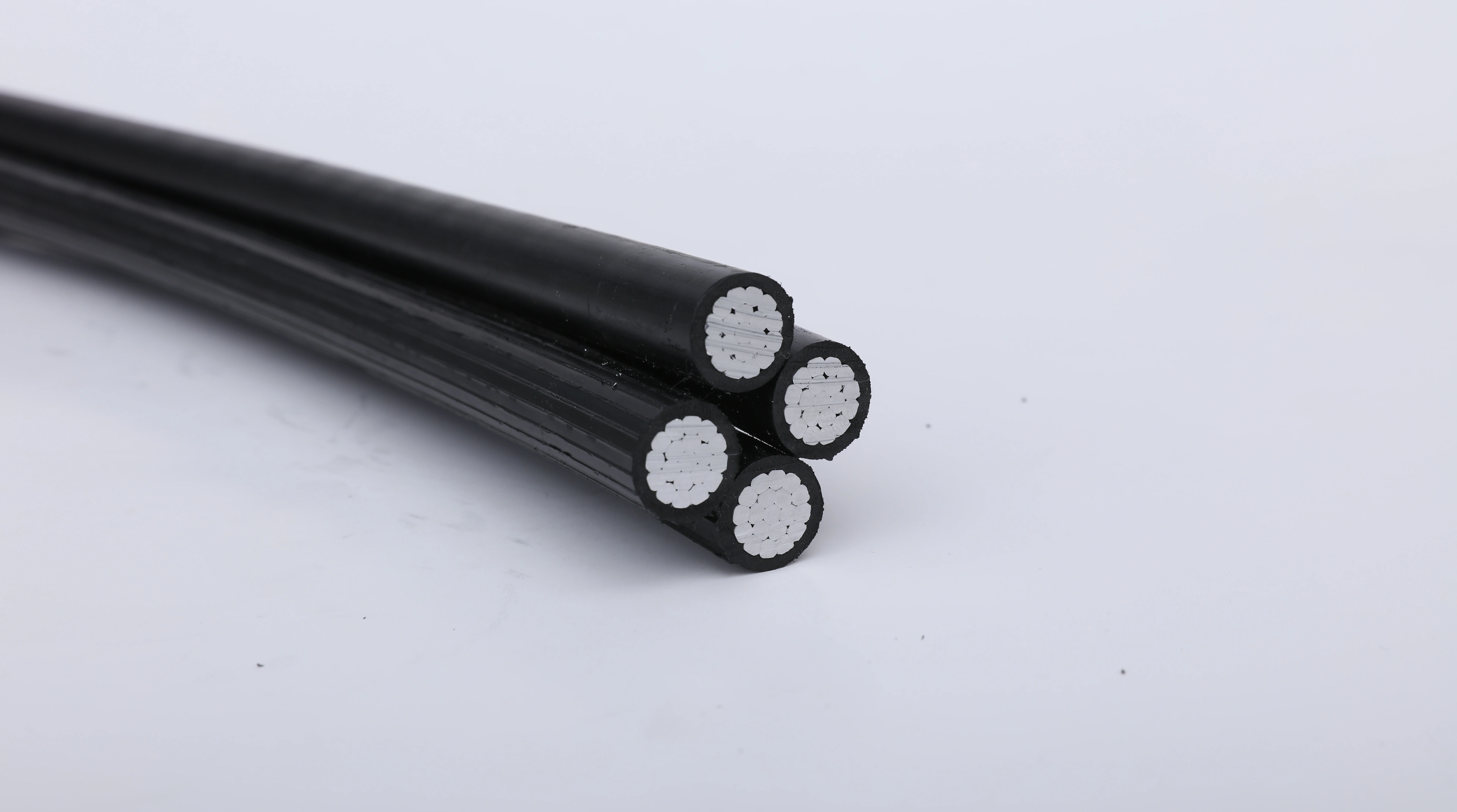

Model:NPC AAAC Cable & Triplex Cable x 10km

Technical Advantages

FAQ From Customers

-

What is the difference between wires and cables?

A wire is a single conductor that carries electricity, while a cable is a group of two or more insulated electrical wires bundled together. Wires and cables are used to transmit electrical power or signals, but cables provide better protection and are often used where safety and durability are critical. -

How do I choose the right electrical cable for my project?

When selecting an electrical cable, consider the required voltage, current capacity, installation environment, and safety standards. For example, choose power cables for high-load transmission, solar cables for photovoltaic systems, or insulated electrical wires for indoor wiring. Always ensure the cable meets international standards such as IEC, UL, or ISO. -

What are the common types of wires and cables?

Common types include bare conductor cables for overhead transmission, power cables for industrial and residential electricity supply, solar cables for renewable energy systems, insulated cables for building wiring, grounding wires for safety, and submarine cables for undersea power transmission. -

Why is testing important for electrical wires and cables?

Testing ensures wires and cables meet safety, durability, and performance standards. High-quality electrical cables undergo conductivity, insulation, fire resistance, and mechanical strength tests to guarantee reliable operation. Properly tested electrical wires reduce energy loss, prevent short circuits, and increase system safety. -

Can NPC Electric provide customized wires and cables solutions?

Yes. With over 30 years of manufacturing experience, NPC Electric offers customized wires and cables, including electrical cables and electrical wires designed to specific voltage levels, insulation types, and installation conditions. Our engineering team supports custom solutions for power transmission, industrial automation, renewable energy, and infrastructure projects worldwide.