Wires and Cables

UL standard

TW AND THW

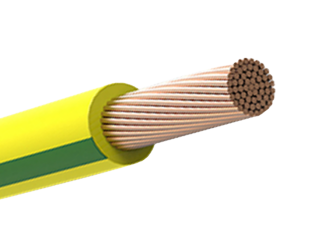

Electrical wire TW AND THW is used in new construction projects or rewiring tasks in 600-volt systems. It is from NPC Electric are designed for building wiring applications where dependable electrical performance and installation safety are required. These single-core copper conductors are insulated with high-quality thermoplastic materials, providing stable conductivity, good mechanical protection, and resistance to heat and moisture. TW wire is suitable for dry or damp locations with moderate temperature ratings, while TH wire offers higher heat resistance for applications requiring enhanced thermal performance. Manufactured under strict quality control, NPC Electric TW and TH Wires deliver uniform insulation thickness, consistent conductor structure, and long service life. Their reliable performance and ease of handling make them a trusted choice for residential, commercial, and light industrial electrical installations.

THHN AND THWN

Electrical wire THHN THWN is used in new construction projects or rewiring tasks in 600-volt systems. Versatile and usable in both wet and dry locations, THHN/THWN-2 is an excellent choice for a wide range of electrical installations. THHN/THWN-2 conductors can withstand temperatures up to 90°C in dry environments and up to 75°C in the presence of oil or coolant. Its outer nylon jacket is smooth and fine, ensuring easy installation by reducing friction during pulling. This feature is especially useful for long or challenging runs.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, NPC control & instrument cable exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

NPC building wire have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

Building Wire Manufacturer

Building Wire Durability & Safety

Building Wire Conductivity & Performance

Testing & Quality Control

Product Show

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

ISO Environmental Certificate

ISO Occupational Certificate

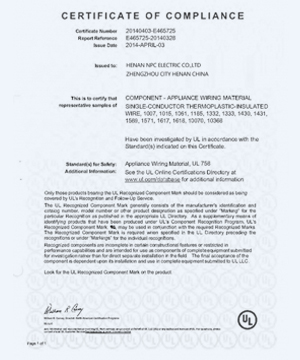

UL Laboratory Certificate

UL Product Certificate

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

Model:NPC AAAC Cable & Triplex Cable x 10km

Technical Advantages

FAQ From Customers

-

What is UL standard building wire?

UL standard building wire refers to electrical wiring that meets the safety and performance standards set by Underwriters Laboratories (UL). UL is a global safety certification organization that tests and certifies electrical products to ensure they meet safety, fire resistance, and electrical conductivity requirements. UL standard building wire is designed for use in residential, commercial, and industrial electrical systems, ensuring safe and reliable operation in a wide range of environments. -

Why is UL certification important for building wire?

UL certification ensures that building wire meets rigorous safety standards, protecting both the electrical system and users. UL-certified wires are tested for fire resistance, electrical performance, and mechanical durability to ensure they can withstand harsh conditions. Using UL standard building wire helps meet national electrical codes and ensures that installations are compliant with safety regulations, reducing the risk of electrical hazards, such as short circuits, overheating, and fires. -

What are the advantages of using UL standard building wire?

The advantages of using UL standard building wire include enhanced safety, reliability, and performance. UL-certified wires undergo thorough testing for electrical conductivity, flame resistance, and durability. They are designed to provide optimal power transmission while ensuring fire safety and reducing the risk of electrical faults. UL standard wire offers peace of mind, knowing that the wire has been tested to the highest safety standards and is suitable for both residential and industrial applications. -

What types of building wire meet UL standards?

UL standard building wire comes in a variety of types depending on voltage rating, application, and environment. Common types include:

1. Low Voltage Building Wire (up to 600V), typically used in residential and commercial wiring.

2. Medium Voltage Wire (600V to 15kV) used in industrial or power distribution systems.

3. Fire-Resistant Cables designed for use in high-risk environments.

4. Flexible and Armored Cables for dynamic applications that require protection against physical damage.

All of these wires meet UL 83, UL 1063, and other UL standards, ensuring compliance and reliability in various electrical systems. -

How does UL standard building wire differ from non-UL certified wire?

UL standard building wire is tested and certified to meet strict safety standards, ensuring reliable electrical performance and compliance with national electrical codes. Non-UL certified wire may not have undergone the same rigorous testing and could pose higher risks of electrical failure, overheating, or fire hazards. UL-certified wire is also traceable, ensuring it has been manufactured to meet the required specifications, offering greater assurance of safety and durability for both residential and commercial electrical installations.