5000kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application EV Charging

- Power Rating 5000kVA

- Certificate UL

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 5000 kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 3500 kg |

| Total Weight | 9700 kg |

| Outline Dimensions(L×W×H)in. | 2880×2200×2100(mm) |

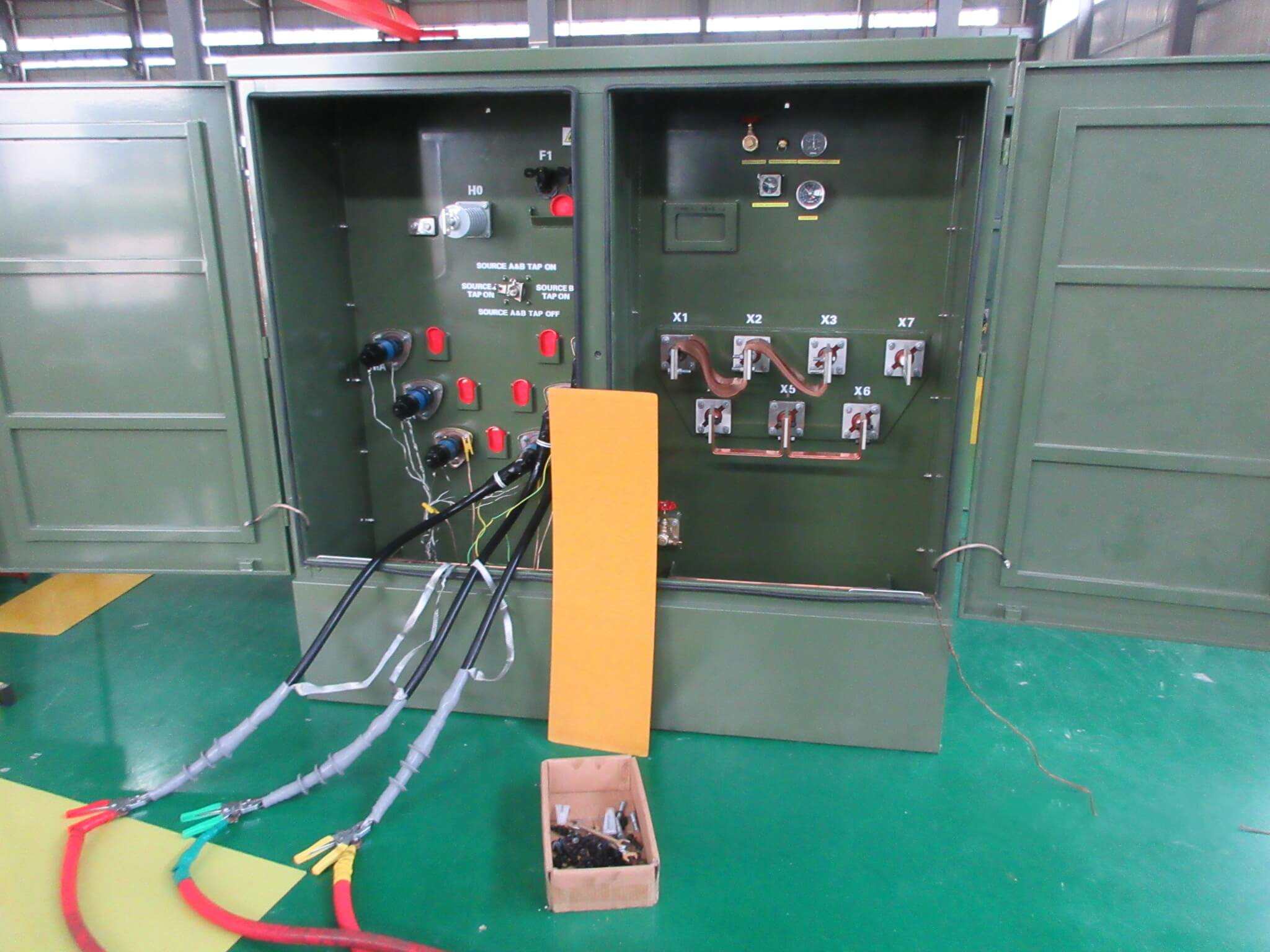

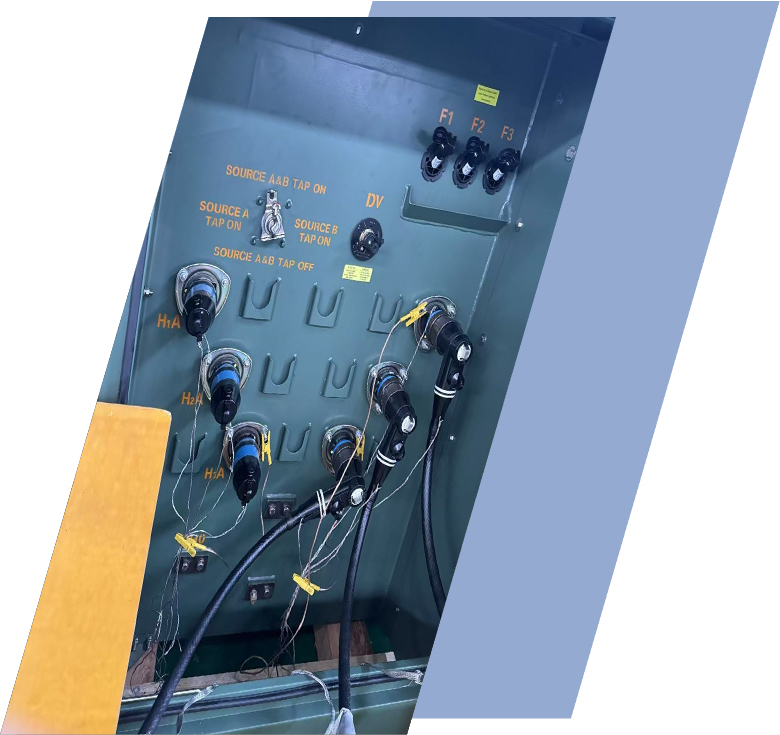

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

Provides natural oil circulation cooling (ONAN) or forced air cooling (ONAF) to optimize heat dissipation performance according to actual load and environmental conditions. Optional transformer with load tap changer to facilitate voltage regulation and maintain stable voltage output.

Different types of insulating oils such as mineral oil, environmentally friendly vegetable oil or silicone oil can be selected according to application requirements to ensure environmental protection and high temperature performance. Optional reinforced insulation design is available to adapt to special environmental conditions such as high humidity, high pollution or high altitude areas.

These optional specifications enable the 5000kVA three-phase box-type transformer to be customized according to specific application scenarios and customer needs, ensuring its stable and reliable operation in various environments.

Packing and Shipping

The unit rests on a heavy-duty steel skid or reinforced export-grade wooden base, wrapped in volatile corrosion inhibitor (VCI) paper, multi-layer shrink film, and desiccant pouches to control humidity and prevent oxidation. Full oil-filled transport uses nitrogen blanketing for positive pressure; partial filling with separate sealed IBCs or drums lightens load (dry weight ~8000-10000 lbs, total ~22000-25000 lbs) and satisfies hazmat regulations. Removable bushings and fittings gain protective wooden enclosures and bracing.

Packaging follows ISPM-15 heat-treated lumber standards with steel strapping, edge reinforcements, and high-visibility labels indicating weight (approx. 10-12 tons filled), center of gravity, lift points, dimensions (~96-100" W x 96-108" D x 94-112" H), and warnings ("High Voltage Equipment - Specialized Handling Required"). Compartment doors lock with tamper-evident seals; weatherproof covers shield HV/LV bushings and accessories.

Domestic shipping employs lowboy trailers or extendable flatbeds for oversize loads, complete with permits, pilot/escort vehicles, and pre-planned routes to navigate restrictions. International options include 40ft open-top or flat-rack containers, or break-bulk/Ro-Ro ocean freight, with certified lashing (chains, turnbuckles, timber blocking) to secure against maritime forces. Real-time GPS tracking monitors progress; full cargo value insurance protects against loss or damage.

At destination, detailed instructions guide safe unloading via lifting lugs/jacking points, pad leveling, oil replenishment (if partial), grounding, and commissioning checks. Customs facilitation includes commercial invoices, packing lists, certificates of origin, test reports, and compliance documentation for efficient clearance. Pre-shipment third-party inspections or customer witnessing can be coordinated for added verification. Our logistics ensure regulatory compliance, reduced transit risks, and transformer arrival in optimal state ready for installation.

Manufacturer Test

Progress test

During 5000kVA pad mounted transformer production, core flux density validation optimizes magnetic performance to minimize hysteresis and eddy losses. Insulation drying in vacuum ovens logs temperature and vacuum profiles for complete dryness before oil contact. High-voltage lead positioning and clearance checks comply with BIL levels for surge resilience. Initial post-tanking oil fill allows low-voltage dielectric and excitation proving. Accessory functional progress cycles load-break switches, fuses, tap changers, gauges, and alarms repeatedly for reliability. Paint application measures dry film thickness, cure status, and adhesion for long-term environmental protection. Pre-acceptance audits verify nameplate accuracy, labeling, color consistency, and overall assembly readiness. Cumulative progress testing enables swift corrections, ensuring smooth advancement to full factory acceptance and dependable long-term service.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory acceptance testing (FAT) for the 5000kVA three phase pad mounted transformer complies with IEEE C57.12.90, C57.12.00, and client protocols to confirm performance before release. Routine visual/mechanical inspections review enclosure welds, paint quality, nameplate data, accessory mounting, and tamper-resistant elements. Winding resistance across all taps at reference temperature verifies conductor uniformity and loss calculations. Turns ratio (TTR) testing on every position ensures ratio accuracy within 0.5% and proper vector group. Polarity and phase relation checks align with specified connections. Insulation resistance at 5kV megger evaluates winding-to-winding/ground paths for high megohm values. Applied potential withstand applies one-minute test voltage to HV/LV per BIL class without breakdown or corona.

Routine Test - DC Insulation Resistance Test

Voltage source (usually 500V, 1000V, 2500V, or customized according to customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test to ensure that the test conditions meet the standard requirements.)

Perform the test under suitable environmental conditions. It is recommended to have a relative humidity below 75%, no rain, and a temperature range of 20-30°C to avoid moisture or temperature fluctuations affecting the test results.

Connect an insulation resistance tester to the high voltage terminal of the device under test and to ground.

Apply Test Voltage:

Select an appropriate test voltage based on the rated voltage of the equipment .

Insulation resistance value (MΩ)

Applied voltage

Ambient temperature and humidity during testing

500 MΩ ≤ Insulation resistance < 1000 MΩ (good)

100 MΩ ≤ Insulation resistance < 500 MΩ

Insulation resistance < 100 MΩ

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.