250kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2 or others

- Secondary Voltage Ratings 208Y/120V, 480Y/277V, or 240/120V or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application warehouses, school campuses, small data closets

- Power Rating 250kVA

- Certificate UL

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 250kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 3500 kg |

| Total Weight | 9700 kg |

| Outline Dimensions(L×W×H)in. | 2880×2200×2100(mm) |

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

Packing and Shipping

For longer shipments or export, the unit is placed in reinforced wooden crates or open-top cases with internal bracing, foam padding, and anti-vibration materials to counter road, rail, or sea movements. Oil-filled units ship under vacuum or nitrogen pressure to maintain insulation dryness; extra fluid, if required, is shipped in sealed drums with absorbent packaging. Sensitive items like gauges and relief valves receive additional shock-absorbing protection.

In North America, domestic deliveries use flatbed trailers with secure strapping, chains, and blocking per DOT guidelines; typical weight (~2,500–3,500kg) and dimensions (~1.8m L × 1.5m W × 1.6m H) often avoid oversize permits. International shipments utilise 20ft or 40ft flat-rack/open-top containers on RoRo vessels, lashed and chocked to IMO standards for stability. Inland transport employs air-ride trailers to minimise vibrations. Every shipment includes full insurance, GPS tracking, and detailed paperwork (packing list, bill of lading, test reports, customs docs).

Upon arrival, visual inspection verifies no transit damage, with immediate claims processed under warranty. These thorough packing and shipping procedures prevent mechanical harm, fluid contamination, or environmental exposure, ensuring the transformer arrives ready for prompt installation and dependable performance in distribution networks.

Manufacturer Test

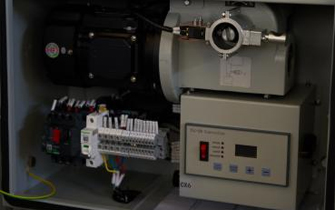

Progress test

The 250kVA pad mounted transformer before shipment. Load loss/impedance short-circuit test at rated current measures copper losses (corrected to reference temperature) and impedance (3.1–5.75% nominal, ±7.5% tolerance) confirming efficiency and fault limits. Applied voltage withstand applies power-frequency potential verifying insulation to ground/between windings. Routine impulse test (reduced/full wave) confirms BIL withstand (typically 95kV) via waveform. Zero-sequence impedance measured if needed for grounding. Functional tests check pressure relief (35 SCFM activation), gauges, and tap changer reliability. Final visual/mechanical inspection verifies ANSI C57.12.28 tamper resistance, coating, bushing alignment, grounding, and labeling. Combined losses verify DOE efficiency compliance.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

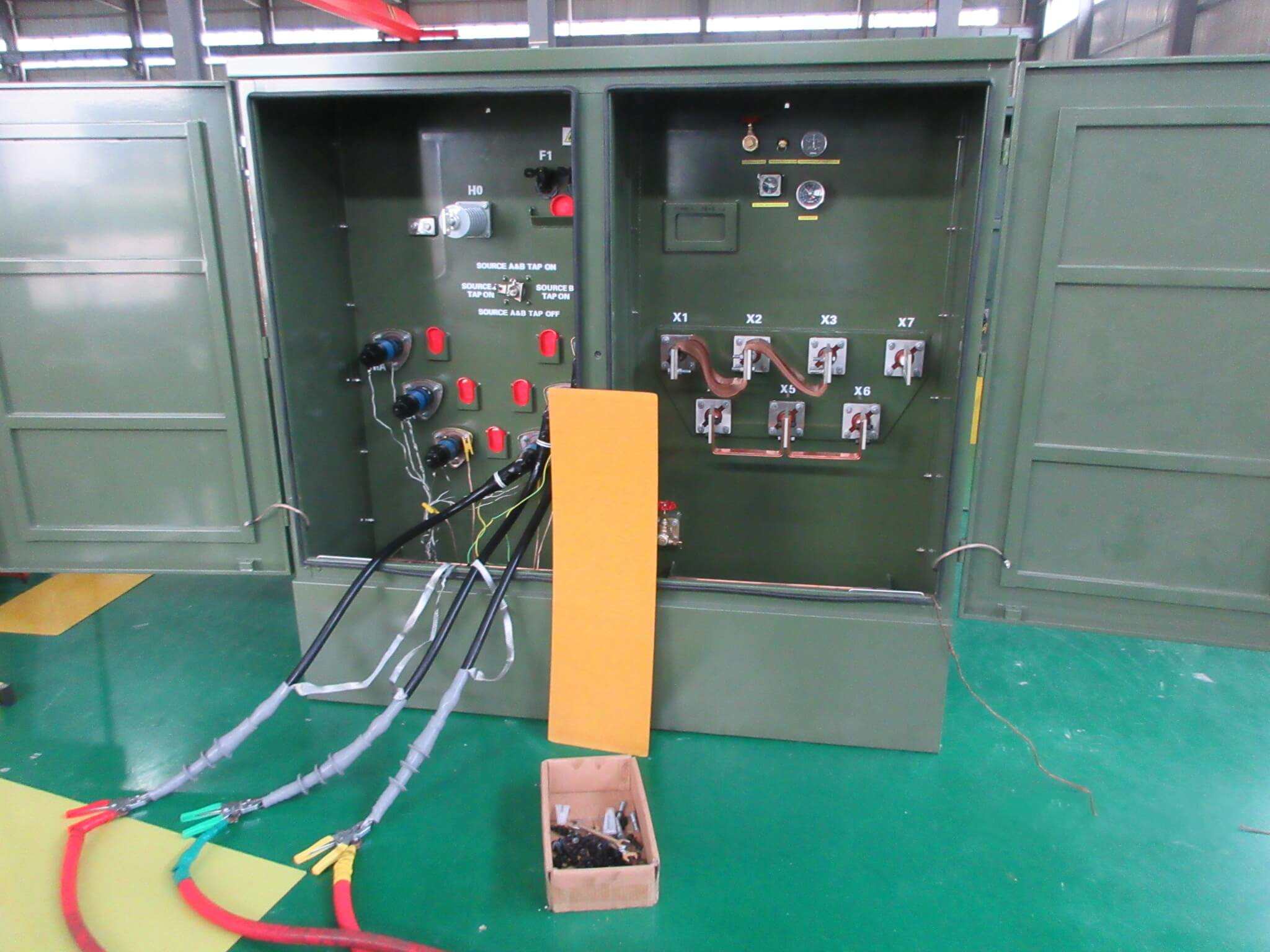

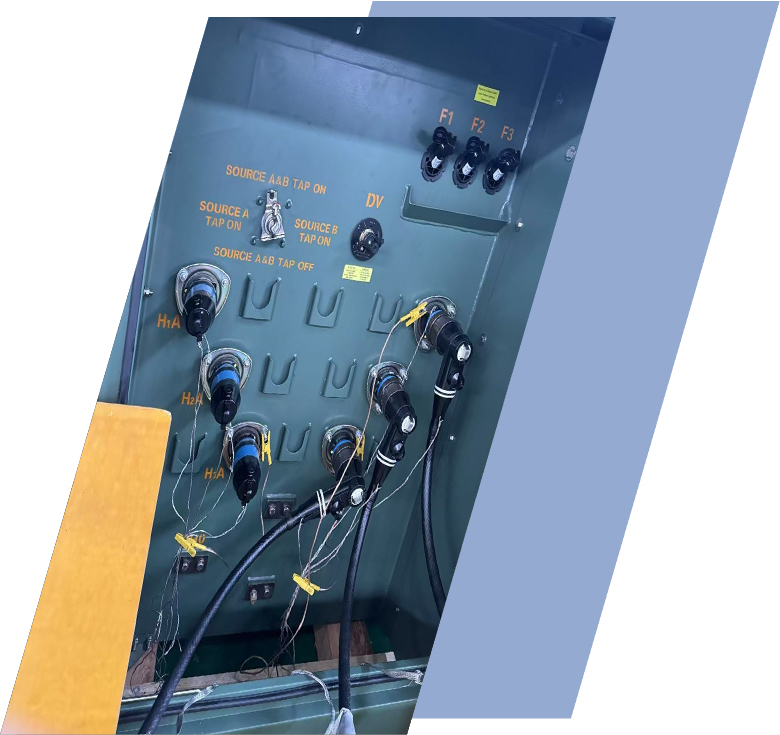

Transformer Factory Acceptance Test

Supplementary FAT routines focus on load/dielectric/system aspects for the 250kVA pad mounted transformer. Load loss/impedance short-circuit quantifies copper losses (temperature-corrected) and percent impedance (3.1–5.75%) ensuring efficiency/fault control. Applied voltage withstand confirms main insulation strength without flashover. Routine impulse test (reduced/full waves) validates BIL (95kV typical) with waveform integrity. Zero-sequence impedance supports protection if required. Control functions test gauges, relief device activation, and tap changer response. Final visual/mechanical inspection checks ANSI C57.12.28 tamper-proof enclosure, paint quality, bushing setup, grounding, and nameplate. Total losses/efficiency verify against guarantees. Comprehensive FAT report includes data tables, curves, photos, and tolerances (losses ≤+10% guaranteed, impedance ±7.5%), proving compliance for reliable shipment and installation.

Routine Test - DC Insulation Resistance Test

Voltage source (usually 500V, 1000V, 2500V, or customized according to customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test to ensure that the test conditions meet the standard requirements.)

Perform the test under suitable environmental conditions. It is recommended to have a relative humidity below 75%, no rain, and a temperature range of 20-30°C to avoid moisture or temperature fluctuations affecting the test results.

Connect an insulation resistance tester to the high voltage terminal of the device under test and to ground.

Apply Test Voltage:

Select an appropriate test voltage based on the rated voltage of the equipment .

Insulation resistance value (MΩ)

Applied voltage

Ambient temperature and humidity during testing

500 MΩ ≤ Insulation resistance < 1000 MΩ (good)

100 MΩ ≤ Insulation resistance < 500 MΩ

Insulation resistance < 100 MΩ

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.