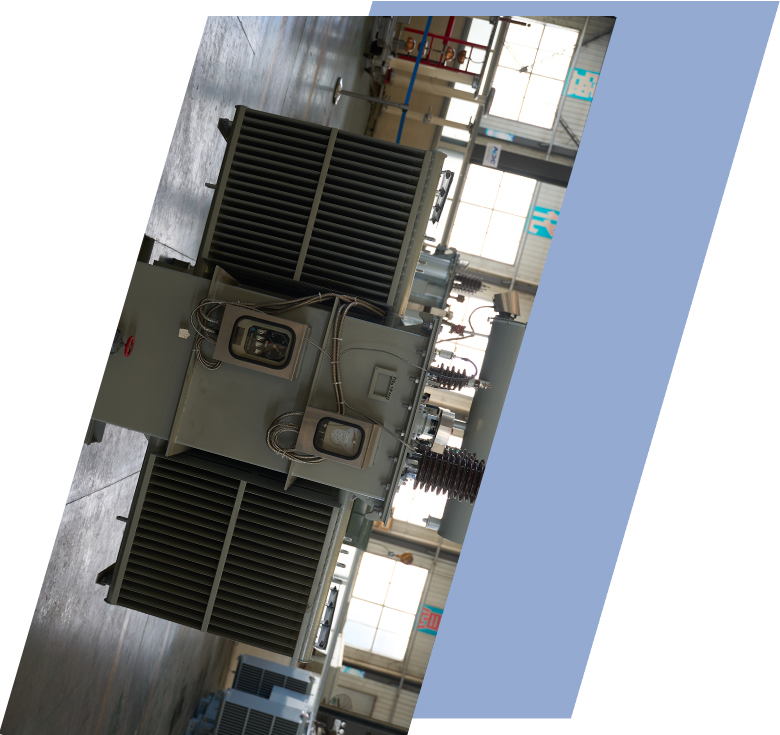

5000kVA Oil Immersed Substation Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed distribution transformer

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application Temporary Power Supply Systems, Utilities

- Power Rating 5000kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 5000kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 850 kg | |

| Total Weight | 5000 kg | |

| Outline Dimensions(L×W×H)in. | 2650 × 1650 × 2450(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

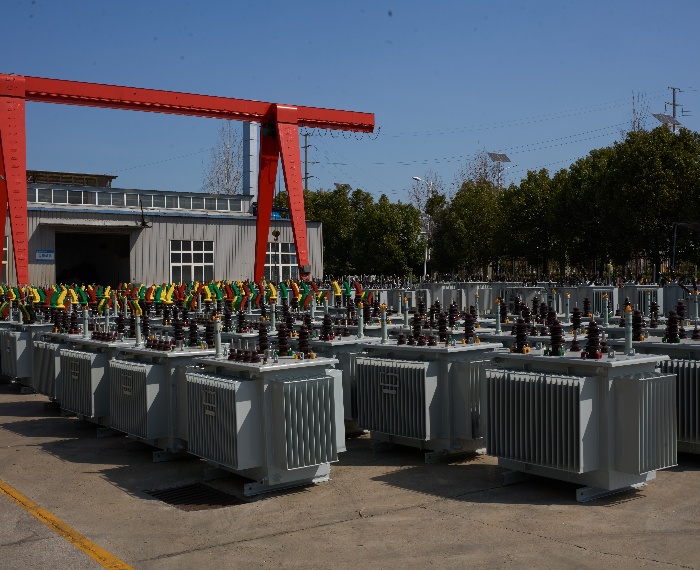

Packing and Shipping

The transformer is mounted on a heavy-duty base designed to withstand long-distance transportation. Protective wrapping materials are applied to shield the tank surface, bushings, and radiators from vibration, impact, and environmental exposure. Packing solutions comply with international logistics standards, ensuring the 5000kVA oil immersed substation transformer remains stable and protected during sea freight, land transport, or combined shipping methods.

Shipping arrangements are planned according to customer delivery terms and project schedules. The manufacturer works with experienced logistics providers to manage loading, route planning, and delivery timelines efficiently. All necessary documentation, including packing lists, inspection records, and conformity certificates, is prepared to support smooth customs clearance and on-time arrival.

Upon delivery, unloading instructions and handling guidance are provided to prevent damage during installation preparation. Reliable packing and professional shipping management help preserve the electrical and mechanical performance of the 5000kVA oil immersed substation transformer, ensuring it reaches the site ready for commissioning.

Manufacturer Test

Progress Test

Throughout manufacturing, the 5000kVA Oil Immersed Substation Transformer is subjected to systematic progress tests that monitor quality at each production stage. Core stacking inspections verify magnetic path accuracy to control losses, while winding formation tests ensure mechanical stability and electrical consistency. Intermediate measurements, including insulation resistance and turns ratio verification, are conducted to confirm that the 5000kVA oil immersed substation transformer maintains design parameters before final assembly, reducing the risk of defects and rework. Drying processes, oil filling supervision, and partial electrical checks are carried out to ensure optimal dielectric performance. By embedding the product specifications into every inspection step, the factory ensures the 5000kVA oil immersed substation transformer consistently meets performance expectations and operational reliability requirements prior to final testing.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The Factory Acceptance Test for the 5000kVA Oil Immersed Substation Transformer is conducted in accordance with international transformer standards. Test items include winding resistance measurement, voltage ratio and vector group verification, applied voltage withstand tests, and insulation power factor assessment. Each procedure directly evaluates the electrical safety and functional accuracy of the 5000kVA oil immersed substation transformer, ensuring compliance before shipment. No-load and load loss measurements, temperature rise evaluation, and oil dielectric strength tests are performed to validate operational readiness. Completion of the FAT process confirms that the 5000kVA oil immersed substation transformer can operate reliably within demanding substation environments and long-term service conditions.

Routine Test - Winding Resistance

Test voltage source (commonly used are 6V, 10V, 20V, 40V or 100V, depending on the equipment model or customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test)

Disconnect the electrical connection between the test cable and the equipment to ensure that there is no external current or voltage interference.

Select a suitable voltage range for testing and set the test voltage according to the equipment requirements.

Connect the test equipment to the winding terminals of the device under test, making sure the connections are secure and properly grounded to avoid measurement errors.

Apply Test Voltage:

Select the appropriate test current according to the equipment specifications (such as test current for low-voltage windings, single-phase or three-phase windings).

Winding resistance (usually expressed in units of "Ω")

Test current (A)

Test voltage (V)

Temperature (record the winding temperature before and after the test)

Resistance deviation is between 5% and 10% (warning)

Resistance deviation exceeds 10% (further inspection or corrective action is required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.