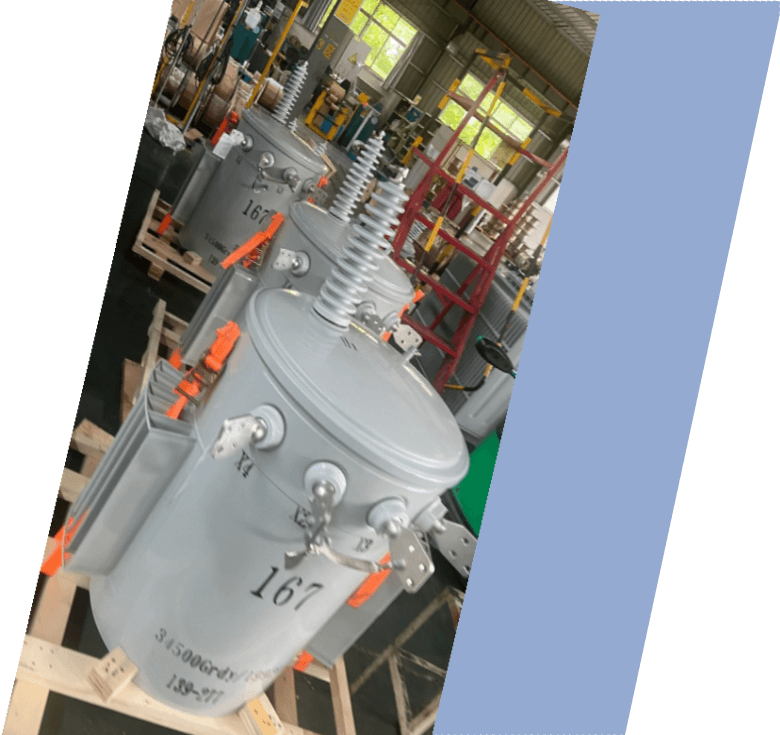

333kVA Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 2.4-34.5kV

- Secondary Voltage Ratings 480-240/240-120 or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 30-150kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application Residential, commercial, agricultural and light industrial

- Power Rating 333kVA

- Certificate CE, ISO

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 333kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 218 kg |

| Total Weight | 980 kg |

| Outline Dimensions(W×D×H) | 915×960×1735 (mm) |

| Lifting Lug |

| Tap Changer |

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

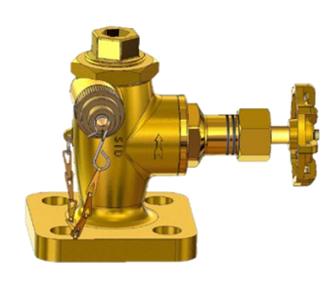

| Oil fill valve |

Customization Optional

Packing and Shipping

Shipping solutions are optimized for this large-capacity transformer, utilizing specialized heavy-haul trailers with hydraulic suspensions for domestic overland moves, secured with heavy chains, binders, and protective tarpaulins against weather exposure. Overseas transport relies on flat-rack or open-top containers on ocean vessels, with lashing compliant to IMO standards and corrosion preventives for prolonged sea voyages. For time-critical shipments, air freight can be arranged via charter, though ground and sea remain primary due to size. Advanced tracking through satellite and GPS systems, along with all-risk insurance coverage, provides full visibility and financial protection. Compliance with global regulations, including IEC, IEEE, and customs documentation, expedites clearance and reduces potential delays for seamless delivery.

Sustainability drives our packing strategy, incorporating responsibly sourced, recyclable timber and minimizing single-use plastics while consolidating shipments to lower environmental impact. Transit impact recorders monitor forces, enabling verification of handling quality upon receipt. Pre-shipment third-party inspections confirm secure loading and accessory inventories. Our network of vetted carriers, experienced in oversized electrical cargo, adheres to strict safety protocols and permit requirements for road, rail, and port handling.

Delivery support extends to site-specific coordination, including route surveys for challenging access and guidance on unloading with cranes or pole-setting equipment. Detailed manuals outline re-oiling, connection torques, and initial energization steps. This thorough logistics framework guarantees the 333kVA single phase pole mounted transformer reaches destinations intact, ready for rapid installation, and contributes to uninterrupted power reliability in critical infrastructure deployments.

Manufacturer Test

Progress Test

As manufacturing progresses for the 333kVA single phase pole mounted transformer, core construction tests involve verifying grain-oriented steel stacking with laser alignment for minimal air gaps and burr removal, followed by epstein frame loss measurements to confirm core losses stay below targeted values. Winding fabrication includes conductor tension monitoring and insulation layer hipot testing at incremental voltages to ensure no weak points. Inter-turn insulation resistance is checked with high-frequency pulses, targeting values over 500 megohms. Preliminary ratio testing uses digital bridges to validate turns accuracy within 0.15% tolerance across taps. Core assembly clamping torque is verified to specification, and vibration response is assessed to simulate field conditions. Oil batch certification checks acidity, breakdown voltage exceeding 40kV, and moisture below 8ppm. Tank weld inspections employ magnetic particle and ultrasonic techniques for defect-free seams, while bracket load tests confirm structural capacity. All interim data feeds into quality dashboards for real-time corrections.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory acceptance testing for the 333kVA single phase pole mounted transformer begins with full external examination, confirming adherence to dimensional drawings, surface coating quality, nameplate details, and accessory mounting. Winding resistance is precisely measured using micro-ohmmeters with temperature compensation to 80°C, ensuring results within 0.8% of calculated values. Turns ratio and polarity across all taps are validated with high-accuracy TTR instruments, holding errors under 0.2%. Dielectric dissipation factor and capacitance at 12kV confirm tan delta below 0.35%, verifying insulation health. No-load performance testing at rated voltage measures losses and magnetizing current, aligning with DOE efficiency tiers and keeping excitation under 1.2%. Short-circuit impedance and load losses are determined accurately via reduced-voltage method, yielding efficiency figures above 98%. Power frequency withstand applies appropriate kV levels for one minute without issues. Induced overvoltage at elevated frequency stresses insulation integrity. Oil parameters include dielectric strength over 45kV and low gas content via DGA.

Routine Test - Transformer Turns Ratio/TTR

Voltage source: usually AC 10 V to 30 V , used to test different voltages for each tap.

Temperature and humidity meter: used to record environmental conditions during the test to ensure test accuracy.

Current probe: used to measure the load current of the winding and ensure the accuracy of the test results.

Perform the test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C). Avoid high humidity or bad weather that may affect the test accuracy.

The voltage ratio between the windings

Deviation of the measured value from the rated ratio

0.5% < Turns ratio error ≤ 1% (caution)

Turns ratio error > 1% (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.