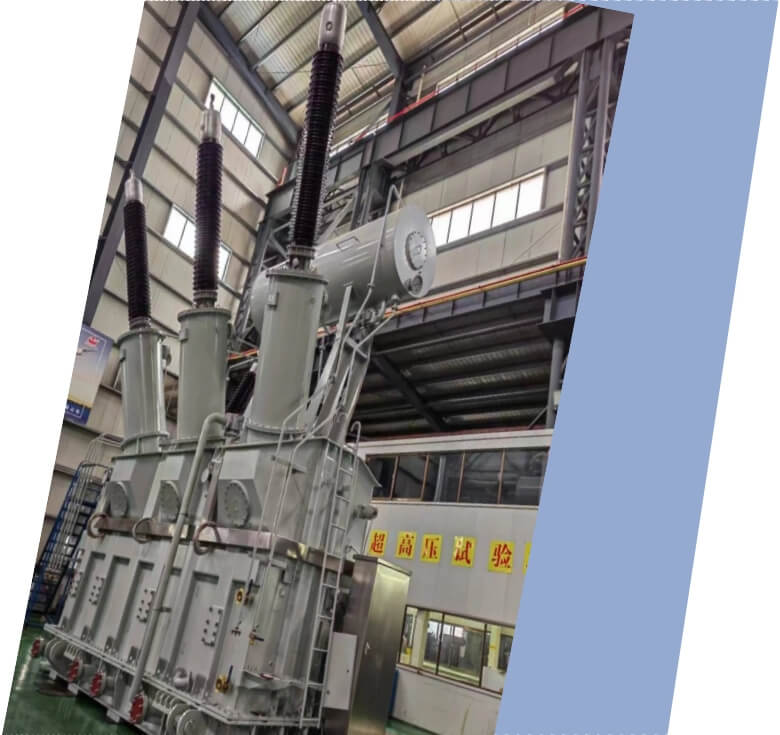

100kV 200kVA 250kVA 315kVA Three-Phase Oil-Immersed Substation Power Transformer

- Primary Voltage Ratings 100kV, 110kV, 115kV or others

- Secondary Voltage Ratings 11/10.5/6.6/6.3kV or customized

- H.V. Tap Range ± 8×2.5% HV taps or others

- Type Oil-immersed power transformer

- BIL up to 350kV

- Standards IEEE, ANSI, IEC

- Application high-voltage distribution substations, industrial power systems, utility grids, and regional electrical networks

- Power Rating 200kVA 250kVA 315kVA

- Certificate UL , CESI , CE

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 200kVA 250kVA 315kVA |

| Rating Primary Voltage | 100kv, 110kV, 115kV |

| Secondary Voltage |

6.3 kV 6.6 kV 10.5 kV 11 kV Customized |

| Frequency | 50/60Hz |

| Vector Group | Dyn11, YD11, YNd11 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE, CAS Std or Customized |

| Impedance Voltage | As IEC |

| Altitude | ≤1,000m or Customized |

| Enclosure material | Mid Steel |

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Customization Optional

Packing and Shipping

Loading operations are conducted with certified lifting equipment to maintain structural integrity. The base of the transformer is equipped with robust lifting lugs and forklift channels to facilitate safe handling. When required, vacuum sealing or nitrogen-filled preservation methods are deployed to maintain internal oil and insulation stability throughout extended transit periods. Every shipment is accompanied by vibration monitoring tags and tilt indicators to ensure the equipment is transported upright and in accordance with manufacturer guidelines.

For international transport, the transformers can be shipped via sea freight, air cargo (for smaller units), or multimodal logistics chains. All shipping documentation—including packing lists, inspection reports, bills of lading, and certificates of origin—is prepared to comply with export requirements in the destination market. Transformers destined for extreme climates may receive additional thermal-stable packaging and anti-rust treatment to ensure readiness upon arrival.

Upon delivery, customers receive a detailed unpacking guide, installation instructions, and recommended storage procedures. Field service support can be arranged for offloading supervision, site inspection, and commissioning. Each transformer undergoes a final verification process prior to shipping, ensuring that all components, protective devices, and accessories are complete and ready for immediate deployment.

Manufacturer Test

Progress test

The progress test includes a series of intermediate inspections conducted during transformer production to verify manufacturing quality and compliance with design specifications. Core lamination assembly is inspected for alignment and loss performance, while coil winding procedures are monitored to ensure correct tension, insulation layering, and conductor accuracy. Oil tank fabrication and welding undergo dimensional checks and non-destructive testing to guarantee structural integrity. Electrical clearances, insulation materials, and tap-changer mechanisms are verified during assembly. Partial discharge tests, ratio checks, and resistance measurements may be performed during key production stages to confirm stability and alignment with technical requirements.

Design Tests

All transformers will be tested after finishing the production test items as below:

♦ Leak testing with pressure for liquid-immersed transformers

♦ Test of transformer oil

♦ Measurement of voltage ratio and check of phase displacement

♦ Measurement of winding DC resistance

♦ Measurement of d. c. Insulation resistance between each winding to earth, and check of the core and frame insulation

♦ Capacitive bushing test

♦ Measurement of dissipation factor (tan δ) of the insulation system capacitances, and determination of capacitances windings-to-earth

♦ Measurement of no-load loss and current at 90%,100%,110% of rated voltage

♦ Operation test on on-load tap-changer

♦ Measurement of short-circuit impedance and load loss

♦ Lightning impulse test

♦ Induced-voltage test with partial discharge measurement

♦ Auxiliary wiring check

♦ Current transformer test

♦ Frequency response analysis test

Transformer Factory Acceptance Test

Factory Acceptance Testing (FAT) includes a full suite of electrical and mechanical evaluations conducted before shipment. Standard tests include turns-ratio measurement, winding resistance, insulation resistance, vector group verification, and applied and induced voltage tests. No-load loss, load loss, and impedance measurements are performed to ensure the transformer meets efficiency and performance specifications. Dielectric tests, oil quality evaluations, and partial discharge assessments validate insulation strength and stability. Mechanical checks include visual inspection, tank pressure testing, and verification of protection devices and accessories. FAT ensures the transformer complies fully with IEC, IEEE, or customer-specified standards.

Routine Test - No Load Loss Test

Voltage source (usually 230V, 400V or customized according to customer requirements to adapt to different equipment)

Power analyzer (used to measure power loss and efficiency)

Ammeter and voltmeter

Temperature and humidity meter

Please ensure that the test is carried out in a suitable environment with a relative humidity of less than 75% and avoid rainy days or extreme weather (recommended temperature range: 20-30°C).

Connect the test equipment to the high voltage side of the transformer, making sure the wiring is correct and the equipment is grounded.

Apply Test Voltage:

Usually it is 110% of the rated voltage, for example, if the rated voltage of the transformer is 33 KV, apply 36.3 KV (110%).

No Load Current

No Load Loss

Power Factor

Current

Voltage

Temperature and Humidity

No-load loss < 0.2% ≤ 0.5% rated power (good)

No-load loss > 0.5% rated power (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.