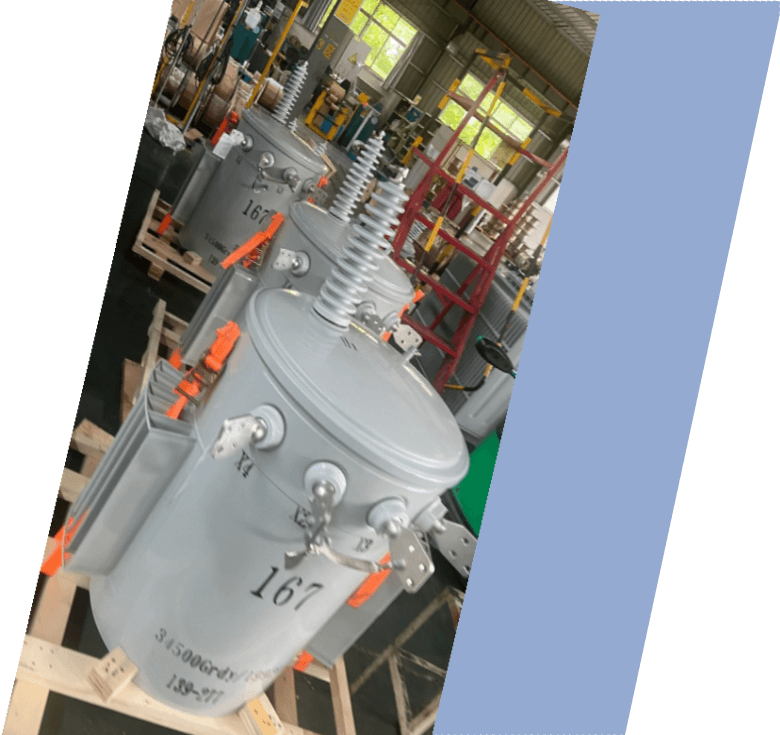

200kVA Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 2.4kV, 11kV, 33kV, 34.5kV

- Secondary Voltage Ratings 480-240/240-120 or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 30-150kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application workshops, retail outlets, public facilities

- Power Rating 200kVA

- Certificate CE, ISO

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 200 kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 158 kg |

| Total Weight | 720 kg |

| Outline Dimensions(W×D×H) | 805×900×1435 (mm) |

| Lifting Lug |

| Tap Changer |

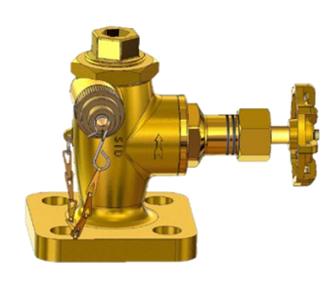

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

| Oil fill valve |

Customization Optional

Packing and Shipping

Shipping logistics are meticulously planned for global reach, utilizing enclosed trailers for overland transport to secure against dust and rain, with tie-downs preventing shifts. For overseas, we opt for standard containers or break-bulk cargo on freighters, applying anti-humidity coatings for marine environments. Expedited air options are available for time-sensitive projects, though limited by cargo holds. Digital tracking systems provide real-time updates, and full-value insurance covers transit risks. Adherence to UN and IATA regulations facilitates quick customs processing, minimizing hold-ups for the 200kVA single phase pole mounted transformer in international markets.

Sustainability is embedded in our process, using eco-friendly, reusable packing materials and optimizing routes to cut carbon emissions. Shock indicators attached to crates record any mishandling, aiding claims if needed. Separate packaging for components like radiators or controls prevents damage, with inventory checklists for verification. Our experienced carriers specialize in oversized electrical equipment, following OSHA guidelines for safe handling. This approach not only preserves product quality but also streamlines costs through consolidated shipments, ideal for bulk orders to distant utilities.

Post-shipment support includes installation guides and virtual assistance for unpacking, with recommendations on torque settings and fluid refills. We collaborate with certified forwarders for door-to-site delivery, navigating challenging terrains. By focusing on efficiency and security, we ensure the 200kVA single phase pole mounted transformer arrives ready for deployment, supporting uninterrupted power infrastructure projects worldwide without logistical setbacks.

Manufacturer Test

Progress Test

In the fabrication stage of the 200kVA single phase pole mounted transformer, initial progress tests focus on core lamination stacking, examining for uniform gaps and magnetic properties using a hysteresis loop tester to keep core losses under 1W/kg. Coil winding integrity is assessed via surge comparison testing, applying impulses to detect turn-to-turn faults with waveform deviations below 5%. Megger testing at 1000V DC between layers confirms insulation resistance over 500 megohms, identifying any contamination. Ratio error measurement with a bridge circuit verifies transformation accuracy within 0.2% across frequencies. Flux density checks use gaussmeters to ensure operation below saturation at 1.7T. Exciting current tests at 110% voltage limit inrush to 10 times rated, confirming design tolerances. Dielectric oil is tested for acidity below 0.01mg KOH/g and interfacial tension above 40mN/m. Mechanical inspections verify tank seam strength via ultrasonic scans, ensuring no voids, and bracket fittings are torque-tested to 50Nm. All data is logged for progressive quality assurance

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory acceptance testing for the 200kVA single phase pole mounted transformer starts with external audits, verifying overall weight, mounting holes, and labeling accuracy per client specs. Resistance measurements on windings use Kelvin bridges at corrected 85°C, with tolerances at 0.75%. Transformation ratio and phase tests via vector analyzers confirm single-phase polarity with errors below 0.3%. Power frequency withstand applies 28kV to primary for 60 seconds without arcing. Capacitance and dissipation factor scans at 12kV limit tan delta to 0.3%. Open-circuit tests measure no-load losses below warranted 500W at rated conditions. Short-circuit evaluations derive load losses and efficiency over 97.5%. Lightning impulse tests at 95kV BIL check waveform integrity. Corona inception voltage exceeds 1.2 times rated without discharge. Fluid analysis includes moisture content under 20ppm and PCB-free certification.

Routine Test - No Load Loss Test

Voltage source (usually 230V, 400V or customized according to customer requirements to adapt to different equipment)

Power analyzer (used to measure power loss and efficiency)

Ammeter and voltmeter

Temperature and humidity meter

Please ensure that the test is carried out in a suitable environment with a relative humidity of less than 75% and avoid rainy days or extreme weather (recommended temperature range: 20-30°C).

Connect the test equipment to the high voltage side of the transformer, making sure the wiring is correct and the equipment is grounded.

Apply Test Voltage:

Usually it is 110% of the rated voltage, for example, if the rated voltage of the transformer is 33 KV, apply 36.3 KV (110%).

No Load Current

No Load Loss

Power Factor

Current

Voltage

Temperature and Humidity

No-load loss < 0.2% ≤ 0.5% rated power (good)

No-load loss > 0.5% rated power (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.