167kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application EV Charging

- Power Rating 167kVA

- Certificate UL

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 167 kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 3500 kg |

| Total Weight | 9700 kg |

| Outline Dimensions(L×W×H)in. | 2880×2200×2100(mm) |

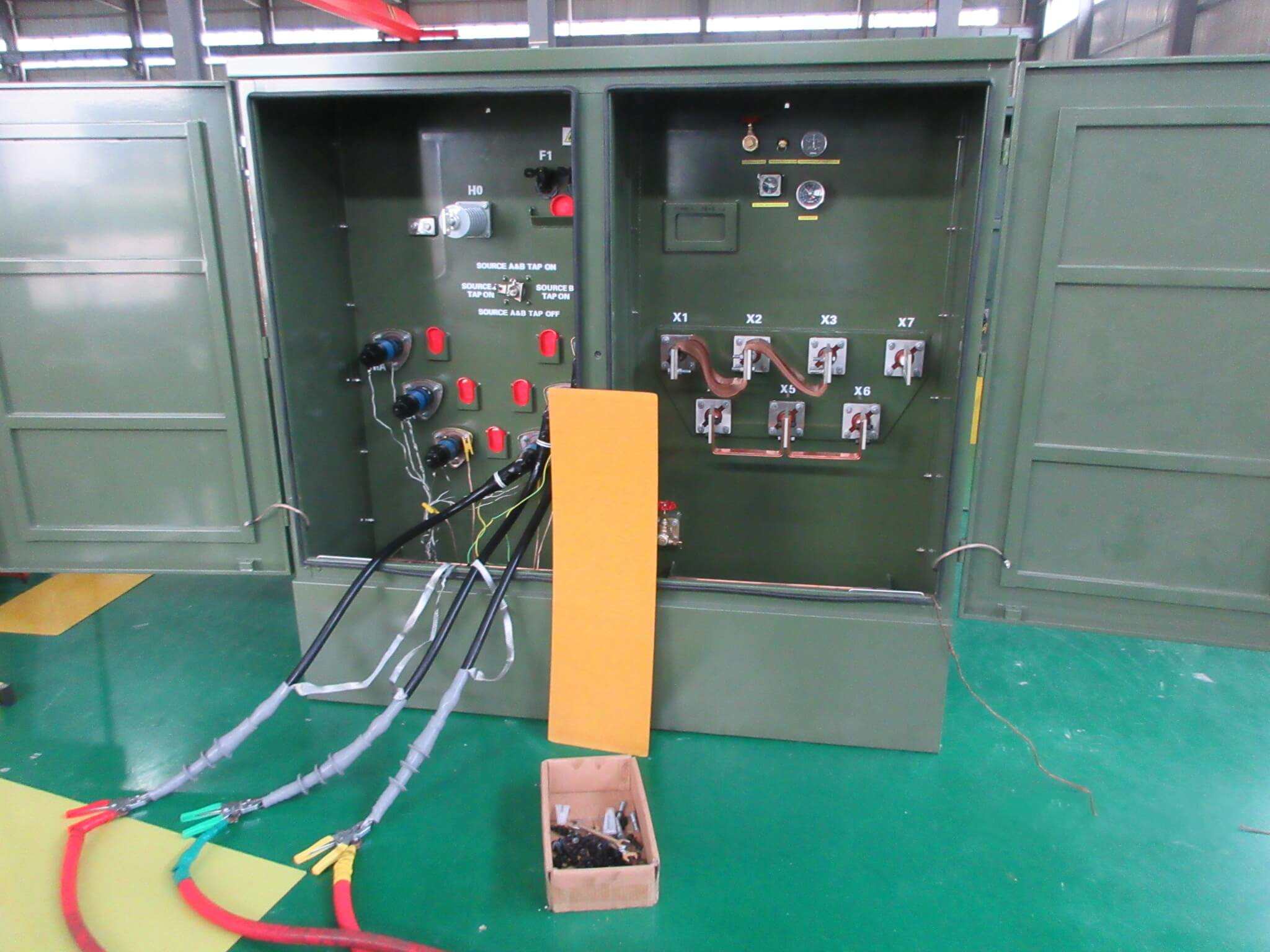

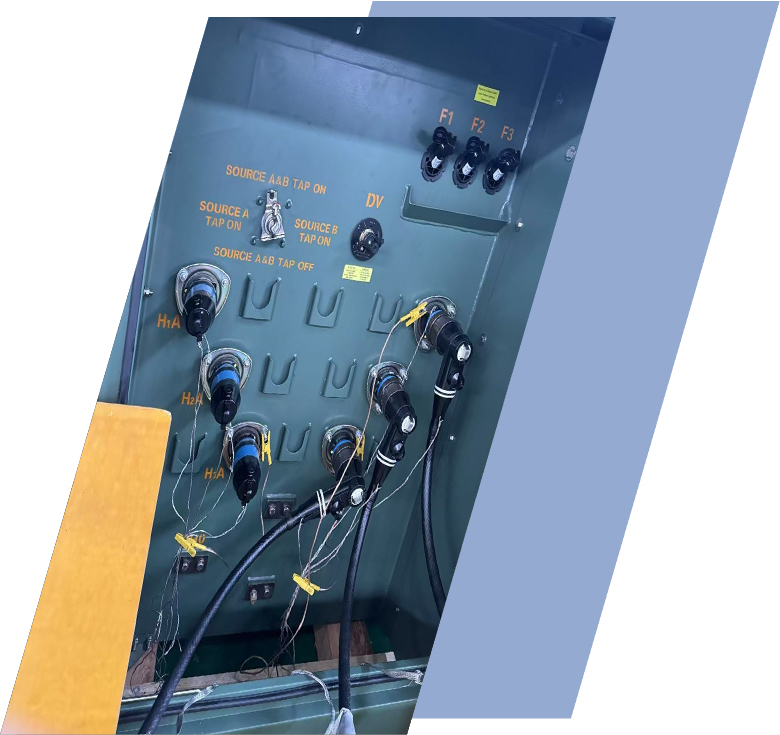

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

Packing and Shipping

For added protection, the entire assembly is encased in a sturdy wooden crate or reinforced case constructed from export-grade timber, fully compliant with international fumigation (ISPM-15) and phytosanitary requirements. Internal bracing and strapping ensure stability, while shock-absorbing materials minimize risks from road, rail, or sea transport vibrations. Lifting lugs remain accessible for safe crane handling, and all external surfaces receive temporary anti-corrosion coating. This packaging approach meets ANSI, IEEE, and export standards, safeguarding the transformer's integrity from factory to site.

Shipping options include containerized sea freight (20ft/40ft HC), flatbed truck for domestic/overland, or specialized heavy-haul carriers for oversized loads. We coordinate with trusted logistics partners to provide full tracking, insurance coverage, and timely customs documentation (commercial invoice, packing list, certificate of origin, test reports). For international shipments, export crating includes desiccant packs and humidity indicators to monitor conditions en route. Lead times vary by destination, with in-stock units often shipping within 1-2 weeks and custom models in 4-8 weeks.

Upon arrival, we recommend professional unloading using the provided lifting provisions and immediate inspection for any transit damage. Our packaging ensures the transformer arrives ready for concrete pad installation, minimizing on-site preparation and reducing overall project costs while maintaining full warranty coverage.

Manufacturer Test

Progress test

During core and coil fabrication, rigorous progress inspections verify quality at key milestones. Core lamination stacking is checked for burr-free alignment, tightness, and proper clamping to minimize eddy current losses. Winding process monitoring includes turn count accuracy, insulation layer uniformity (thermally upgraded kraft paper), and conductor tension to prevent deformation. Vacuum drying and oil impregnation tests confirm moisture removal (<0.5% by weight) and complete penetration. Winding resistance and turns ratio preliminary measurements ensure phase balance (<2% deviation) and correct polarity/vector group. Visual and dimensional checks confirm compliance with design drawings before proceeding to tanking.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Full-wave impulse (BIL) test verifies lightning withstand capability. Partial discharge measurement ensures insulation quality (<10 pC at specified voltage). Functional checks cover tap changer operation (smooth transition, position indication), pressure relief valve activation, liquid level gauge accuracy, and all accessories (drain valve, sampling device). Leak test under pressure confirms hermetic sealing. Oil quality analysis (dielectric strength, moisture, DGA) is performed post-filling. Test data is documented in a certified report, including ambient conditions, ensuring the 167kVA pad mounted transformer meets all contract specifications before shipment.

Routine Test - DC Insulation Resistance Test

Voltage source (usually 500V, 1000V, 2500V, or customized according to customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test to ensure that the test conditions meet the standard requirements.)

Perform the test under suitable environmental conditions. It is recommended to have a relative humidity below 75%, no rain, and a temperature range of 20-30°C to avoid moisture or temperature fluctuations affecting the test results.

Connect an insulation resistance tester to the high voltage terminal of the device under test and to ground.

Apply Test Voltage:

Select an appropriate test voltage based on the rated voltage of the equipment .

Insulation resistance value (MΩ)

Applied voltage

Ambient temperature and humidity during testing

500 MΩ ≤ Insulation resistance < 1000 MΩ (good)

100 MΩ ≤ Insulation resistance < 500 MΩ

Insulation resistance < 100 MΩ

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.