15KV Oil Immersed Substation Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

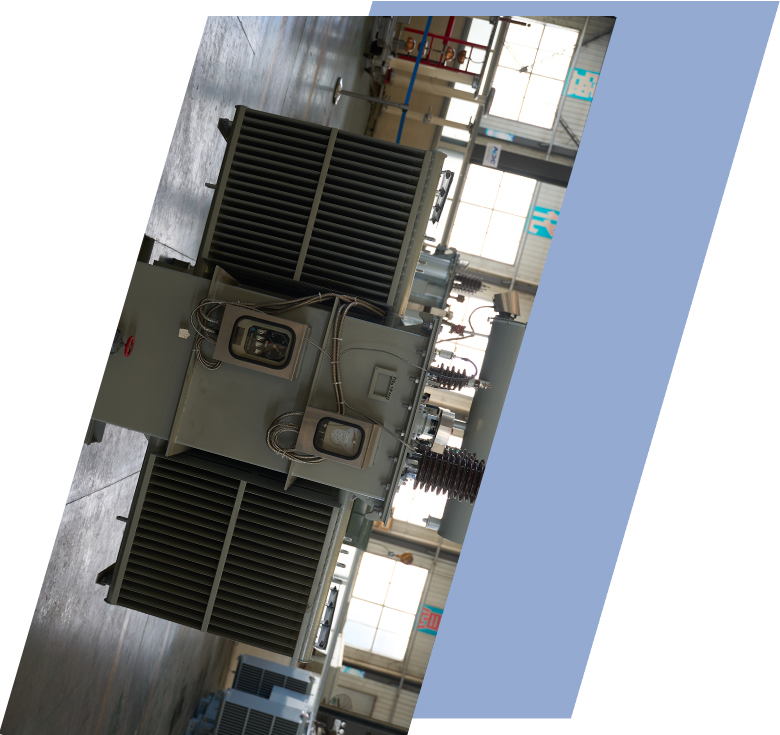

- Type Oil immersed distribution transformer

- BIL 15kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application Temporary Power Supply Systems, Utilities

- Power Rating 30kVA - 5000kVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 30kVA - 5000kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

Packing and Shipping

For packing, the transformer is mounted on a reinforced base designed to support its weight and prevent displacement during transit. Protective materials, including shock-absorbing and moisture-resistant layers, are applied to safeguard the tank surface, bushings, and cooling components. The packing method complies with international transportation standards, making the 15kV oil immersed substation transformer suitable for long-distance sea freight, road transport, or combined logistics solutions.

Shipping arrangements are planned according to customer delivery terms and project schedules. The manufacturer cooperates with experienced logistics providers to ensure safe loading, optimized routing, and timely delivery. Complete shipping documentation, including packing lists, inspection reports, and compliance certificates, is prepared to support efficient customs clearance.

Upon arrival at the installation site, unloading and handling instructions are provided to reduce installation risks. Professional packing and shipping management help maintain the electrical and mechanical integrity of the 15kV oil immersed substation transformer from factory dispatch to site commissioning.

Manufacturer Test

Progress Test

During manufacturing, the 15kV Oil Immersed Substation Transformer is subjected to systematic progress tests that monitor quality at each production stage. Core stacking inspections ensure accurate magnetic paths to control losses, while winding process checks verify conductor arrangement and insulation consistency. Intermediate electrical tests, including insulation resistance and turns ratio measurements, confirm that the 15kV oil immersed substation transformer meets design requirements before final assembly. Drying procedures, oil processing supervision, and sealing inspections are carried out to maintain dielectric stability and prevent leakage. By integrating product parameters into every inspection step, the factory ensures the 15kV oil immersed substation transformer delivers consistent quality and dependable performance prior to final acceptance testing.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The Factory Acceptance Test for the 15kV Oil Immersed Substation Transformer is conducted in accordance with applicable international standards. Test items include winding resistance measurement, voltage ratio and vector group verification, applied voltage withstand testing, and insulation power factor evaluation. These procedures verify the electrical safety and functional accuracy of the 15kV oil immersed substation transformer before shipment. No-load and load loss measurements, temperature rise assessments, and oil dielectric strength tests are performed to validate design performance. Completion of the FAT process confirms that the 15kV oil immersed substation transformer is ready for reliable service in medium-voltage substation applications.

Routine Test - Impulse Tests

Voltage divider (used to measure impulse voltage waveform, resistor divider or capacitor divider)

Oscilloscope (used to record impulse waveform, common brands such as Tektronix, Keysight)

Calibrate and check the impulse voltage generator, measurement system, and control system to ensure that the instruments and equipment are in good condition and meet the test standards.

Connect the impulse voltage generator correctly to each winding terminal (high voltage terminal, ground terminal) of the device under test, and ensure that all test instruments are well grounded.

Apply Test Voltage:

Select the appropriate impulse voltage waveform and amplitude according to the rated voltage of the equipment

Front Time

Time to Half-Value

Peak Voltage

Distortion

Ambient temperature and humidity (especially when the test environment needs to be corrected)

If the waveform deviation is too large, adjust the impulse generator parameters and reapply the test.

In special cases, inter-winding impact, voltage-to-ground impact or coil corner impact are performed (according to the test plan).

Waveforms are stable and meet standard specifications.

Waveform variations between repeated tests are minimal (usually good waveform overlap with no noticeable abnormal excursions).

Application

Technical Advantages

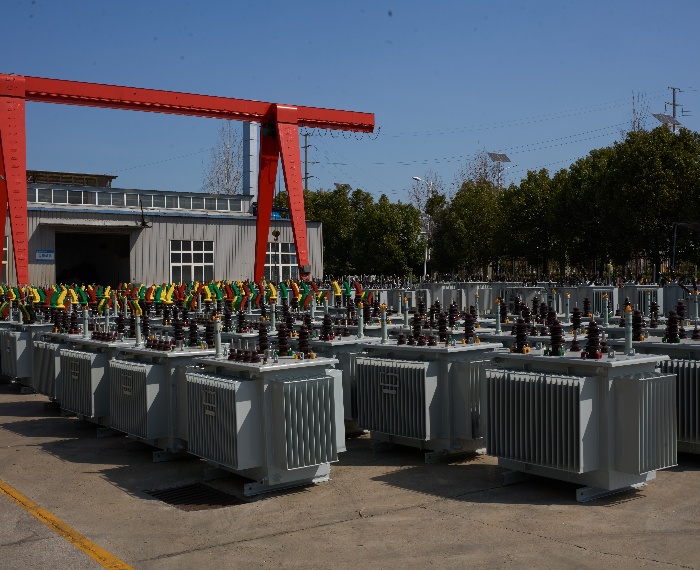

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.