1500kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE,ANSI, CSA, DOE

- Application BESS, Data center, Oil & Gas, Wind & Solar energy

- Power Rating 1500kVA

- Certificate UL, CUL, CSA, SGS

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 1500 kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 800 kg |

| Total Weight | 4400 kg |

| Outline Dimensions(L×W×H)in. | 2200×1500×2100(mm) |

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

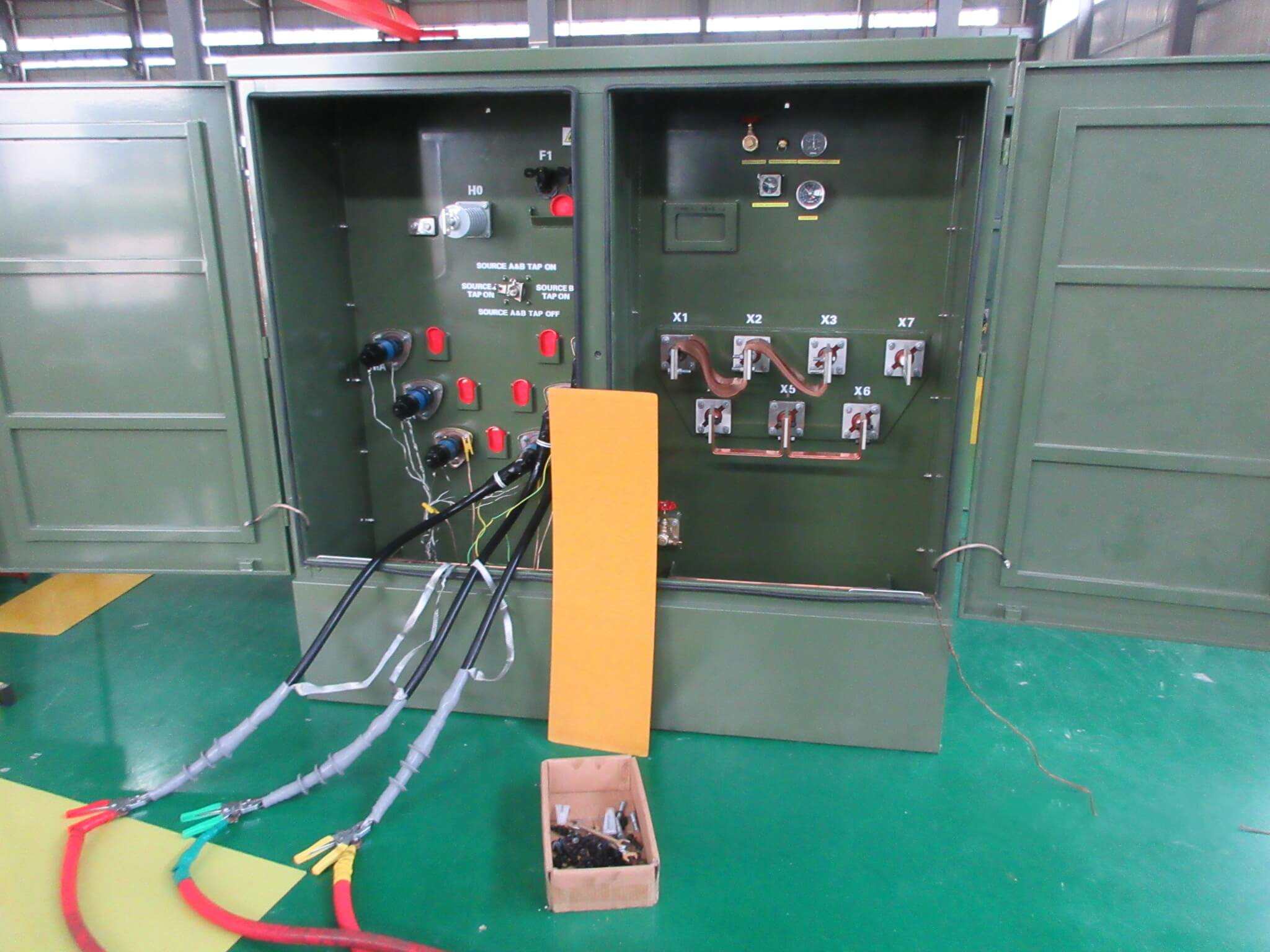

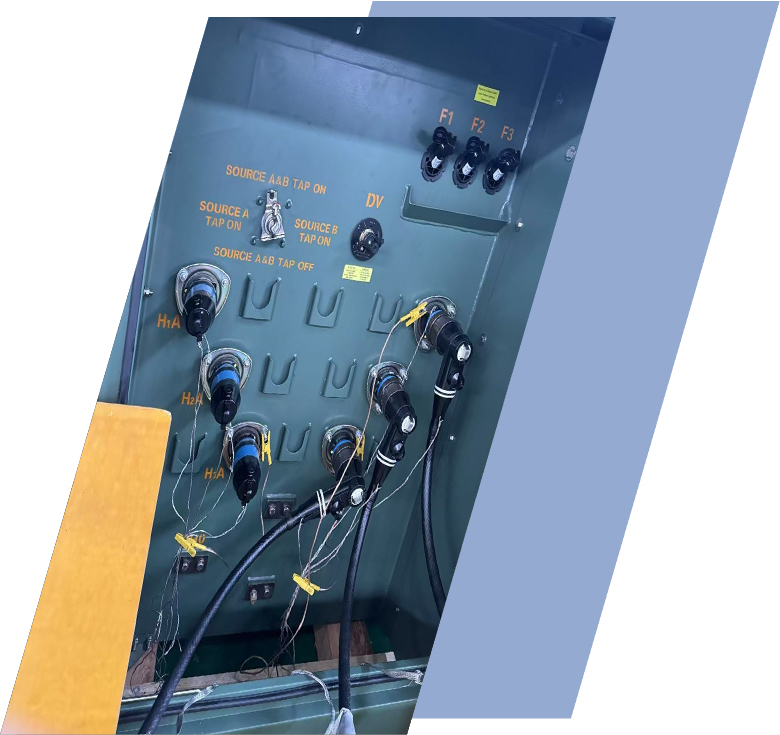

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

The transformer supports two cooling methods: ONAN (natural oil cooling) and ONAF (forced air cooling). Users can choose according to load continuity and ambient temperature requirements. For high temperature or continuous heavy load scenarios, it is recommended to select ONAF to improve cooling efficiency.

The high and low voltage sides support elbow joints (200A/600A), bolted connections and busbar interfaces. Withdrawable fuses and cable branch boxes are also available for easy installation and maintenance. All interfaces comply with ANSI/IEEE standards to ensure compatibility and reliability.

The standard housing is made of hot-dip galvanized steel, and stainless steel can also be used to adapt to humid or corrosive environments. The protection level is NEMA 3R by default, and customers can upgrade to NEMA 4 or IP54 protection levels. The surface color of the housing can also be customized according to customer requirements.

With these flexible options, we ensure that our transformers can be customized for specific applications, environments, and safety standards, offering long-term reliability and performance.

Packing and Shipping

The transformer is packaged with a steel frame or a wooden frame. This structure can effectively protect the transformer from collision and vibration during transportation and prevent any possible damage. The packaging design meets transportation requirements and ensures the stability and safety of the transformer during transportation.

The surface of the transformer is treated with an anti-corrosion coating, which can effectively prevent the equipment from being affected by corrosive substances such as environmental moisture and salt spray during transportation. In addition, the outer layer of the packaging will be covered with a moisture-proof film to further prevent moisture intrusion, thereby ensuring the long-term stability and safety of the equipment.

Depending on the destination and transportation distance of the transformer, sea, land or rail transportation is usually used. For international transportation, sea transportation is usually the most suitable option, especially for large and heavy equipment. For domestic transportation, rail or road transportation can be selected according to the distance to ensure the safe and timely arrival of the transformer.

Through the above detailed packaging and transportation process, the 1500kVA three-phase box-type transformer can ensure that it is fully protected during transportation, reduce transportation risks, and be delivered to customers on time and safely, providing reliable guarantee for the stable operation of the power system.

At delivery, immediate inspection for transit damage, seal/oil level verification, and accessory checks is recommended before unloading. Professional rigging with spreader bars prevents tank distortion. Our logistics team delivers full support, including freight coordination, export documentation (invoices, certificates of origin), and customs assistance to expedite clearance, ensuring the transformer arrives ready for pad mounting, connections, and energization with peak reliability and minimal downtime.

Manufacturer Test

Progress test

NPC Electric manufacture pad mounted transformer have the strict quality control from the Raw material acceptance, including Key component inspection, Core manufacturing inspection, Progress tests during manufacturing of the 1500kVA three phase pad mounted transformer ensure quality control at key production milestones. Core assembly verifies lamination stacking precision, clamping torque, and interlayer insulation resistance to minimize eddy losses and maintain structural strength. Winding processes feature conductor insulation checks, accurate turn/layer alignment, sectional continuity testing, and tension monitoring for uniform coils. Core-coil integration preliminary tests include insulation resistance, hipot screening, and core grounding confirmation. Tank fabrication progress involves weld inspections (ultrasonic/penetrant), hydrostatic leak pressure testing, surface blasting/prep evaluation, and coating thickness measurement. Assembly verifications cover bushing torque application, accessory alignment, gasket compression assessment, and supervised fluid filling or dry-out monitoring to eliminate contamination.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The factory acceptance test (FAT) of the 1500kVA Three Phase Pad Mounted transformer is a series of tests conducted before the transformer leaves the factory to ensure that the product meets the design and quality requirements. The main test contents include electrical performance, load and loss test, temperature rise test and protection system function test to ensure the stability. Factory Acceptance Test (FAT) for the 1500kVA three phase pad mounted transformer commences with detailed visual, dimensional, and mechanical inspections per approved drawings, confirming tank weld quality, enclosure compartmentalization, nameplate accuracy, finish durability, and accessory placement. Insulation resistance megger tests assess windings-to-ground, inter-winding, and core at specified voltages, exceeding minimum thresholds. Precision TTR turns ratio testing validates all taps within ±0.5% tolerance. Polarity, phase sequence, and vector group checks use low-voltage excitation. DC winding resistance measurements are temperature-corrected. No-load loss, excitation current, and efficiency metrics at rated voltage confirm DOE 2016 compliance and low noise levels.

Routine Test - Winding Resistance

Test voltage source (commonly used are 6V, 10V, 20V, 40V or 100V, depending on the equipment model or customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test)

Disconnect the electrical connection between the test cable and the equipment to ensure that there is no external current or voltage interference.

Select a suitable voltage range for testing and set the test voltage according to the equipment requirements.

Connect the test equipment to the winding terminals of the device under test, making sure the connections are secure and properly grounded to avoid measurement errors.

Apply Test Voltage:

Select the appropriate test current according to the equipment specifications (such as test current for low-voltage windings, single-phase or three-phase windings).

Winding resistance (usually expressed in units of "Ω")

Test current (A)

Test voltage (V)

Temperature (record the winding temperature before and after the test)

Resistance deviation is between 5% and 10% (warning)

Resistance deviation exceeds 10% (further inspection or corrective action is required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.