(N)TSCGECEWOU - 3.6/6kV, 6/10kV, 8.7/15kV and 12/20kV Submersible Cable

- Voltage Rating Uo/U 3.6/6kV | 6/10kV | 8.7/15kV | 12/20kV

-

Test Voltage

3.6/6kV: 11kV

6/10kV: 17kV

8.7/15kV: 24kV

12/20kV: 29kV -

Temperature Rating

Fixed: -40°C to +80°C

Flexed: -25°C to +60°C -

Minimum Bending Radius

Fixed: 6 x overall diameter

Flexed: 10 x overall diameter - Maximum Permissible Water Temperature +40°C

- Submersible 300mtr

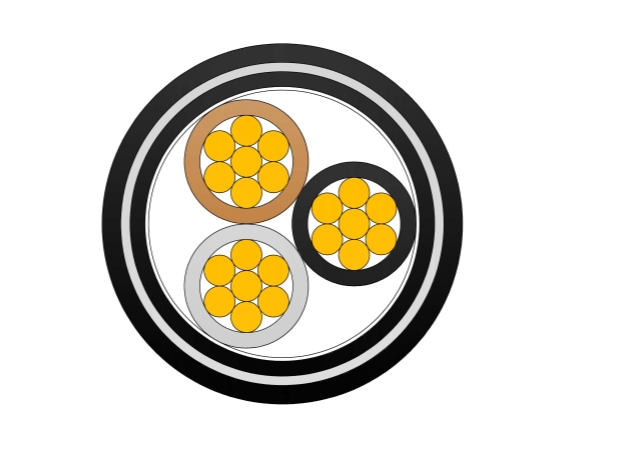

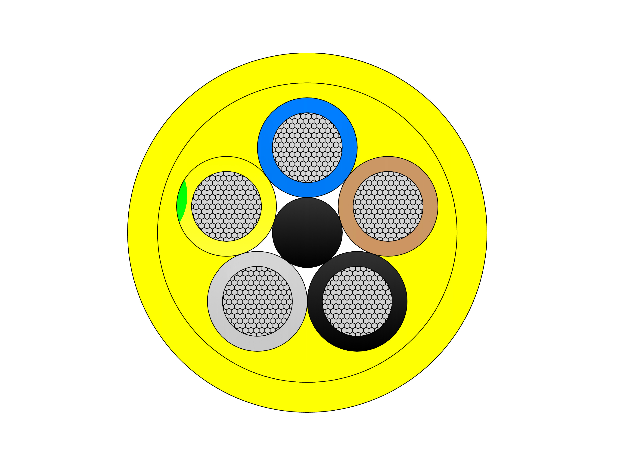

Construction

Phase Conductor

Insulation

Protective Earth Conductor

Central Filler

Inner Sheath

Outer Sheath

Sheath Colour

Manufacturer Standard

Flame Retardant

Semi-Conductive Layers

Semi-conductive rubber layer on the insulation

Application

Technical Specifications

|

No. Of Cores |

Nominal Cross Sectional Area mm² |

CONDUCTOR DIAMETER |

MINIMUM OVERALL DIAMETER |

MAXIMUM OVERALL DIAMETER |

MAXIMUM TENSILE LOAD |

NOMINAL WEIGHT |

|

|

Phase N Conductor |

Earth Conductor |

mm | mm | mm | N | kg/km | |

| 3+3 | 25 | 25/3E | 6.8 | 43.4 | 45.1 | 1125 | 2830 |

| 3+3 | 35 | 25/3E | 7.8 | 45 | 46.7 | 1575 | 3180 |

| 3+3 | 50 | 25/3E | 9.4 | 48.1 | 49.8 | 2250 | 3830 |

| 3+3 | 70 | 35/3E | 11.2 | 53.7 | 55.5 | 3150 | 4960 |

| 3+3 | 95 | 50/3E | 12.7 | 58.4 | 60.2 | 4257 | 6170 |

| 3+3 | 120 | 70/3E | 14.4 | 62.9 | 65.2 | 5400 | 7540 |

| 3+3 | 150 | 70/3E | 16.3 | 69.3 | 71.7 | 6750 | 9050 |

| 3+3 | 185 | 95/3E | 17.6 | 72.1 | 74.5 | 8325 | 10350 |

|

No. Of Cores |

Nominal Cross Sectional Area mm² |

CONDUCTOR DIAMETER |

MINIMUM OVERALL DIAMETER |

MAXIMUM OVERALL DIAMETER |

MAXIMUM TENSILE LOAD |

NOMINAL WEIGHT |

|

|

Phase N Conductor |

Earth Conductor |

mm | mm | mm | N | kg/km | |

| 3+3 | 25 | 25/3E | 6.8 | 43.4 | 45.7 | 1125 | 2870 |

| 3+3 | 35 | 25/3E | 7.8 | 45 | 47.3 | 1575 | 3220 |

| 3+3 | 50 | 25/3E | 9.4 | 48.1 | 50.4 | 2250 | 3870 |

| 3+3 | 70 | 35/3E | 11.2 | 53.7 | 56.1 | 3150 | 5000 |

| 3+3 | 95 | 50/3E | 12.7 | 58.4 | 60.8 | 4257 | 6210 |

| 3+3 | 120 | 70/3E | 14.4 | 62.9 | 65.9 | 5400 | 7580 |

| 3+3 | 150 | 70/3E | 16.3 | 69.3 | 72.4 | 6750 | 9090 |

| 3+3 | 185 | 95/3E | 17.6 | 72.1 | 75.2 | 8325 | 10390 |

|

No. Of Cores |

Nominal Cross Sectional Area mm² |

CONDUCTOR DIAMETER |

MINIMUM OVERALL DIAMETER |

MAXIMUM OVERALL DIAMETER |

MAXIMUM TENSILE LOAD |

NOMINAL WEIGHT |

|

|

Phase N Conductor |

Earth Conductor |

mm | mm | mm | N | kg/km | |

| 3+3 | 25 | 25/3E | 6.8 | 49.4 | 51.2 | 1125 | 3430 |

| 3+3 | 35 | 25/3E | 7.8 | 50.9 | 52.7 | 1575 | 3800 |

| 3+3 | 50 | 25/3E | 9.4 | 55.8 | 57.6 | 2250 | 4700 |

| 3+3 | 70 | 35/3E | 11.2 | 59.6 | 61.4 | 3150 | 5670 |

| 3+3 | 95 | 50/3E | 12.7 | 63.3 | 65.6 | 4257 | 6830 |

| 3+3 | 120 | 70/3E | 14.4 | 69.8 | 72.2 | 5400 | 8520 |

|

No. Of Cores |

Nominal Cross Sectional Area mm² |

CONDUCTOR DIAMETER |

MINIMUM OVERALL DIAMETER |

MAXIMUM OVERALL DIAMETER |

MAXIMUM TENSILE LOAD |

NOMINAL WEIGHT |

|

|

Phase N Conductor |

Earth Conductor |

mm | mm | mm | N | kg/km | |

| 3+3 | 25 | 25/3E | 6.8 | 55.9 | 57.7 | 1125 | 4160 |

| 3+3 | 35 | 25/3E | 7.8 | 57.3 | 59.1 | 1575 | 4560 |

| 3+3 | 50 | 25/3E | 9.4 | 60.5 | 62.3 | 2250 | 5300 |

| 3+3 | 70 | 35/3E | 11.2 | 66.1 | 67.9 | 3150 | 6580 |

| 3+3 | 95 | 50/3E | 12.7 | 69.8 | 72.2 | 4257 | 7740 |

Quality Control

Raw Material Test

Raw Material Test for (N)TSCGECEWOU - 3.6/6kV, 6/10kV, 8.7/15kV, and 12/20kV Submersible Cable guarantees submersible-grade quality and water resistance. The rigorous process includes: Supplier Certification Review: Verify class 5 tinned copper meets DIN EN 60228/IEC 60228 for purity (>99.9% Cu), stranding, and tin coating to enhance corrosion resistance in wet environments; EPR insulation and watertight rubber sheath compounds certified to VDE 0250 for submersible specs. Conductor Analysis: Test tinned copper for tensile strength (>200 MPa), elongation (>20%), conductivity (≥97% IACS), and tin layer thickness to ensure durability underwater. Semi-Conductive & Insulation Testing: Semi-conductive layers checked for resistivity, adhesion, and water-blocking properties;

Process inspection

Process Inspection during manufacturing of (N)TSCGECEWOU - 3.6/6kV, 6/10kV, 8.7/15kV and 12/20kV Submersible Cable ensures watertight construction and defect-free production. Steps include: Conductor Stranding: Monitor class 5 stranding for uniform lay length, compactness, and flexibility using online gauges to maintain submersible integrity. Layer Extrusion: Apply semi-conductive screens and EPR insulation at controlled thicknesses; inline scanners, spark testers, and eccentricity monitors detect voids or defects that could compromise water resistance. Screening & Assembly: Braid copper wires with precise coverage/tension for effective shielding; integrate control/monitoring conductors under water-blocking tapes. Water-Blocking & Sheath Extrusion: Apply longitudinal water-blocking compounds and extrude watertight rubber sheath; real-time checks on thickness, adhesion, and pressure sealing.

Finished Product

Finished Product Test verifies that the (N)TSCGECEWOU - 3.6/6kV, 6/10kV, 8.7/15kV, and 12/20kV Submersible Cable meets submersible standards before shipment. The comprehensive procedure includes: Visual & Dimensional Inspection: Examine the full reel for surface defects, uniformity, markings, and measure outer diameter/weight per meter. Electrical Tests: Perform DC resistance, insulation resistance (>1000 MΩ·km), high-voltage withstand (e.g., 11kV for 3.6/6kV, 17kV for 6/10kV, 24kV for 8.7/15kV, 29kV for 12/20kV/5 min), partial discharge, and screen/monitoring continuity per VDE/IEC. Mechanical Evaluation: Test bending radius (6–8× OD), tensile strength, abrasion, tear resistance, and pressure withstand (e.g., 50 bar). Water Resistance & Sheath Performance: Conduct longitudinal water penetration (IEC 60055, 1 bar/14 days), oil immersion, flame retardancy (IEC 60332)

Application

Technical Advantages

Product Packaging

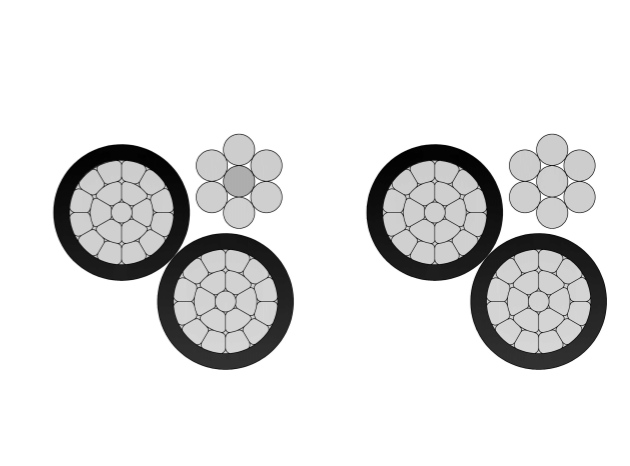

Related Products

FAQ From Customers

-

What are the advantages of power cables and overhead lines?(1) Reliable operation, because it is installed in a hidden place such as underground, it is less damaged by external forces, has less chance of failure, and the power supply is safe, and it will not cause harm to people; (2) The maintenance workload is small and frequent inspections are not required; (3) No need to erect towers; (4) Help improve power factor.

-

Which aspects should be considered when choosing the cross section of a power cable?(1) The long-term allowable working current of the cable; (2) Thermal stability once short circuited; (3) The voltage drop on the line cannot exceed the allowable working range.

-

What are the measures for cable fire prevention?(1) Use flame-retardant cables; (2) Use fireproof cable tray; (3) Use fireproof paint; (4) Fire partition walls and fire baffles are installed at cable tunnels, mezzanine exits, etc.; (5) Overhead cables should avoid oil pipelines and explosion-proof doors, otherwise local pipes or heat insulation and fire prevention measures should be taken.

-

What should be paid attention to during the transportation and handling of cables?(1) During transportation, loading and unloading, cables and cable reels should not be damaged. It is strictly forbidden to push the cable reels directly from the vehicle. Generally, cables should not be transported and stored flat. (2) Before transporting or rolling the cable reel, ensure that the cable reel is firm, the cable is wound tightly, the oil pipe between the oil-filled cable and the pressure oil tank should be fixed without damage, the pressure oil tank should be firm, and the pressure indication should meet the requirements.

-

What inspections should be carried out for the acceptance of cable lines?(1) The cable specifications should meet the regulations, the arrangement should be neat, no damage, and the signs should be complete, correct and clear; (2) The fixed bending radius of the cable, the related distance and the wiring of the metal sheath of the single-core power cable should meet the requirements; (3) The cable terminal and the middle head should not leak oil, and the installation should be firm. The oil pressure of the oil-filled cable and the meter setting should meet the requirements; (4) Good grounding; (5) The color of the cable terminal is correct, and the metal parts such as the bracket are completely painted; (6) There should be no debris in the cable trench, tunnel, and bridge, and the cover should be complete.