800kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application extensive commercial developments, high-rise offices, retail centers

- Power Rating 800kVA

- Certificate UL

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 800kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 3500 kg |

| Total Weight | 9700 kg |

| Outline Dimensions(L×W×H)in. | 2880×2200×2100(mm) |

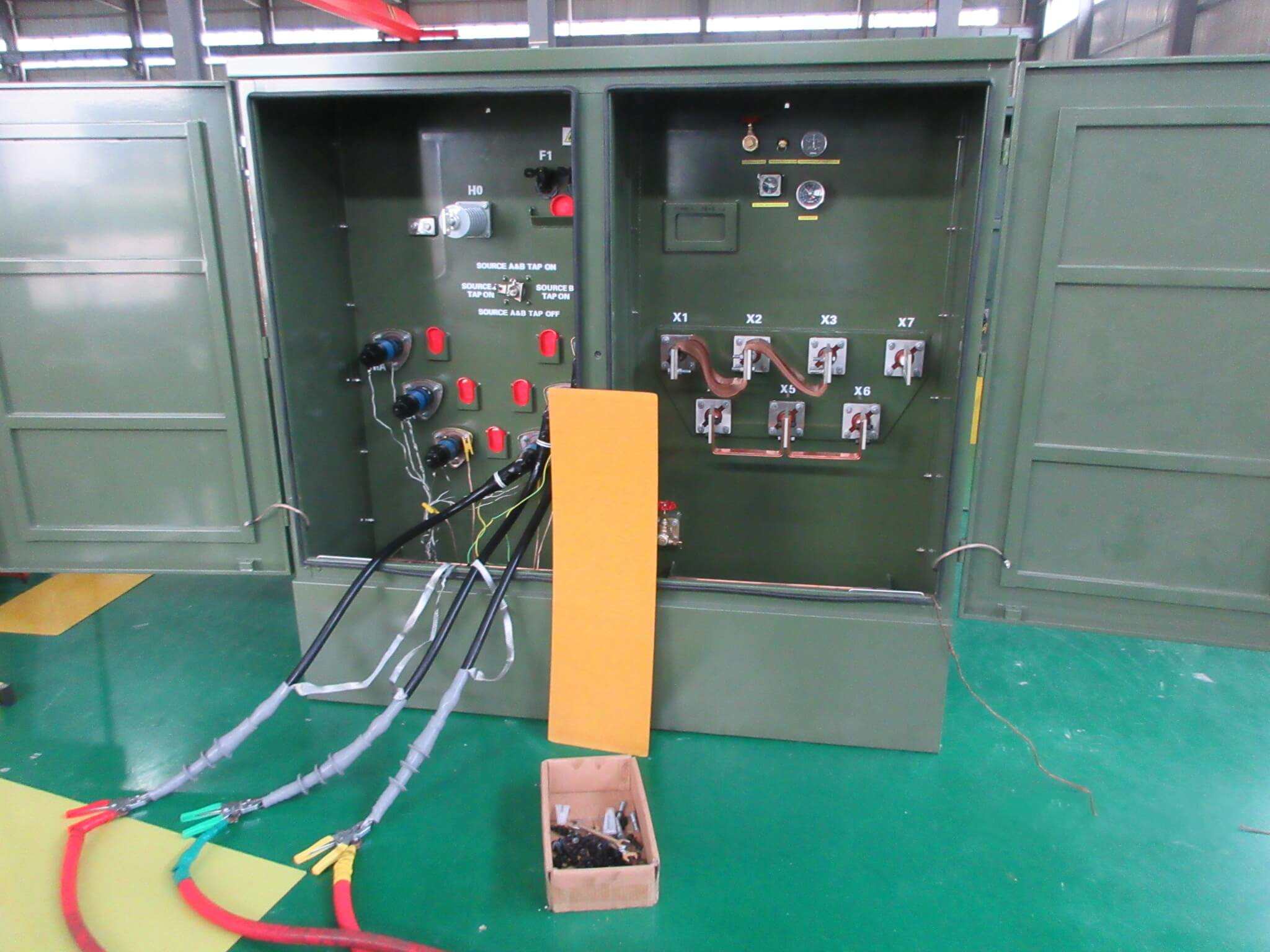

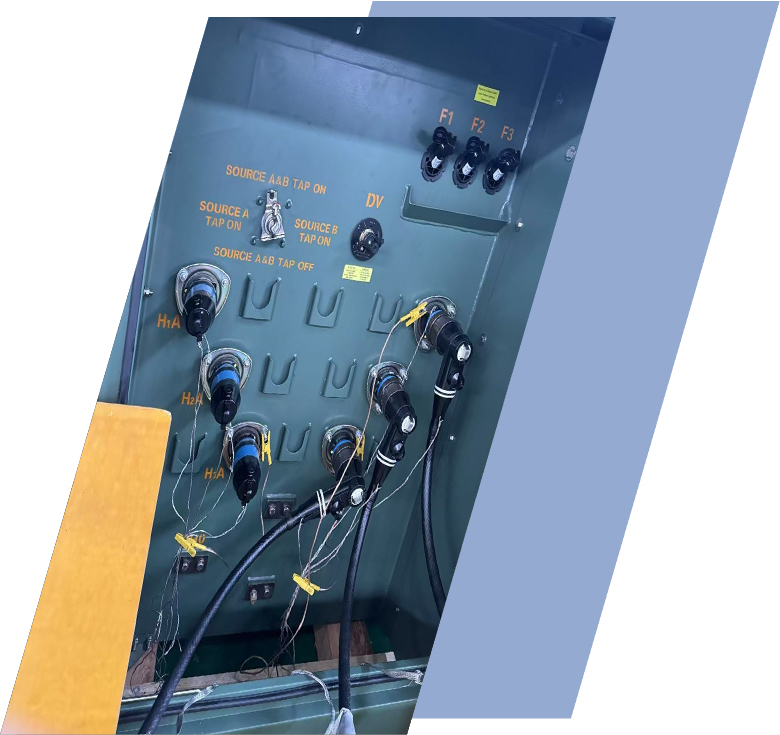

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

Packing and Shipping

For superior safeguarding, the unit is fully shrouded in heavy-duty moisture-proof poly sheeting and hermetically sealed. It is then placed inside a bespoke export-quality wooden crate with reinforced framing, diagonal bracing, and cushioning layers to absorb dynamic loads. Packaging adheres to ISPM-15 international heat-treatment and fumigation norms, with added desiccant agents and humidity monitoring cards to track conditions and prevent condensation issues. External metal surfaces get a protective anti-corrosion treatment, and lifting points remain unobstructed for efficient crane operations, meeting ANSI/IEEE export guidelines.

Transport is facilitated via established carriers with options for 40ft high-cube sea containers (FCL) for overseas shipments, specialized flatbed trailers for overland/domestic routes, or heavy-haul logistics for large-scale movements. Comprehensive services include real-time shipment tracking, full-value marine/land insurance, and thorough export paperwork (invoices, packing lists, origin certificates, test documentation). Typical delivery timelines span 3-5 weeks for standard stock units and 8-12 weeks for customized builds, with priority expediting possible based on availability.

At the destination, unloading should utilize the integrated lifting lugs with appropriate rigging, followed by prompt inspection for shipping-related issues. The robust packaging ensures the transformer reaches the site in optimal condition, primed for immediate pad mounting and commissioning, while upholding the complete warranty and reducing on-site handling requirements or supplementary expenses.

Manufacturer Test

Progress test

With core-coil installed, tank fabrication integrity is evaluated through weld inspections (ultrasonic/dye penetrant), ensuring no leaks. Enclosure components like doors, latching systems, sills, bushings, and accessories are checked for alignment, functionality, and tamper-proof compliance. Tap changer, gauges, valves, and grounding features receive torque and operational verification. Positive/negative pressure testing confirms tank hermeticity before oil filling. Final pre-test inspections cover overall cleanliness, no contaminants, secure nameplate/ground pads, and basic electrical continuity, preparing the unit for exhaustive Factory Acceptance Testing.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Impulse (full-wave BIL) testing assesses surge withstand, complemented by partial discharge evaluation (<5 pC limit). Functional assessments confirm tap changer smoothness/position accuracy, pressure relief operation, gauge precision, and accessory performance (valves, sampling). Tank leak test under pressure ensures sealing, with post-fill oil tests for dielectric breakdown, moisture, and DGA. All outcomes are compiled in a certified report with environmental data, affirming the 800kVA pad mounted transformer satisfies contractual and industry requirements before dispatch.

Routine Test - Polarity 1-Ph

Voltage source: usually 500 V, 1000 V or customized as needed

Environmental monitoring: Temperature and humidity meter (records ambient temperature and humidity)

Check the connection terminals and wiring to ensure that there is no looseness or contamination.

Test under suitable environmental conditions: relative humidity less than 75% and no rain (recommended temperature: 20-30°C).

Connect the test equipment to the bushing or terminal of the device under test and ensure proper grounding.

Apply Test Voltage:

Select the appropriate test voltage according to the rated voltage of the device. For single-phase systems, the applied voltage should comply with the equipment specifications (such as 220V or 380V, etc.).

Phase sequence: Confirm whether the phase sequence of the power supply is correct.

Polarity: Check whether the wiring meets the predetermined polarity (positive and negative terminals are connected correctly).

Voltage: The actual voltage value during the test.following parameters:

Insulation resistance value (MΩ)

Applied voltage

Ambient temperature and humidity during testing

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.