250MVA 330kV High-Voltage Oil-Immersed Distribution Transformer for Grid & Substation

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

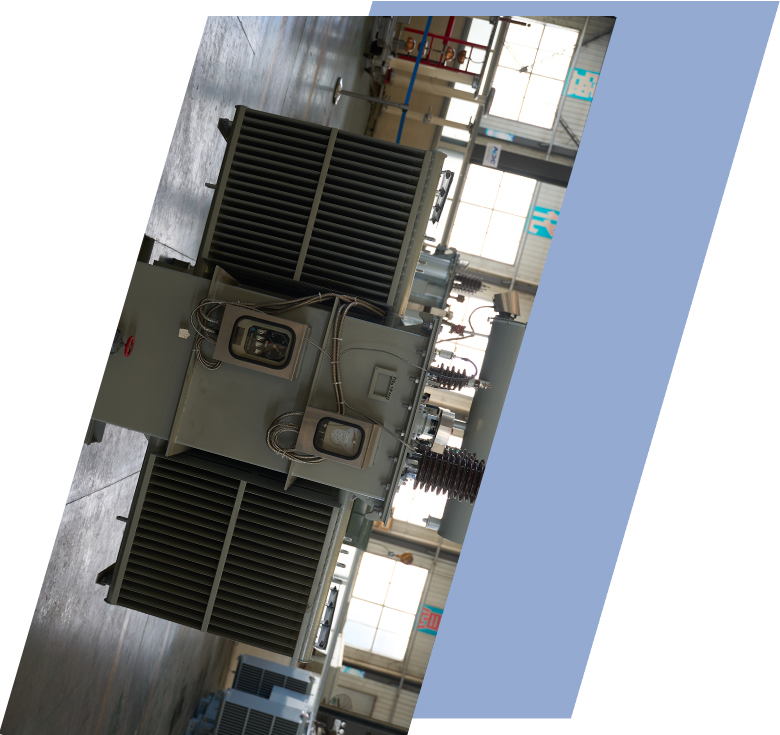

- Type Oil immersed transformer

- BIL 330kV

- Standards IEEE, ANSI, NEMA, IEC, CE

- Application Power Substations, Industrial Power Supply

- Power Rating 250MVA

- Certificate UL, CESI, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 250 MVA | |

| Rating Primary Voltage | 330kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | YNd11 / YNyn0 / Dyn11 / Custom on request | |

| Winding Material | High-conductivity copper (aluminum optional) | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

Packing and Shipping

The main body of the transformer is mounted onto a reinforced steel skid or wooden base designed to support its heavy weight and prevent movement during handling. Multi-layer wrapping, waterproof covers, and high-strength tension straps are applied to safeguard the unit from impact, vibration, and weather exposure. Sensitive components such as OLTC control panels, gauges, and sensors are either removed for separate packaging or reinforced with dedicated protective housings.

For domestic transport, heavy-duty trucks equipped with air-suspension systems are used to minimise vibration. For international shipping, the transformer is loaded onto flat-rack or open-top containers using certified lifting points and cranes to avoid structural stress. All loading operations follow IEC, ISO, and marine transport regulations. Shock and tilt sensors may be installed to monitor transport conditions in real time.

Upon delivery, the unloading process is coordinated with the receiving team to ensure safe handling. A final inspection is performed before removing the protective packaging. This comprehensive packing and shipping procedure guarantees that the 250MVA 330kV oil-immersed transformer arrives safely, intact, and ready for installation.

Manufacturer Test

Progress Test

During the production of the 250MVA 330kV Oil-Immersed Distribution Transformer, several progress tests are conducted to ensure manufacturing accuracy and performance consistency. These include core lamination inspection, coil winding tension checks, and insulation drying verification. Each stage undergoes dimensional measurements, vacuum oil-filling control, and partial discharge assessments. Pressure tightness tests, intermediate electrical tests, and mechanical strength evaluations ensure that assembly quality meets design requirements. Through continuous monitoring, the transformer’s components are guaranteed to meet high-voltage performance and long-term operational reliability.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The Factory Acceptance Test (FAT) for the 250MVA 330kV High-Voltage Oil-Immersed Distribution Transformer verifies compliance with international standards before shipment. FAT includes detailed visual examination, ratio testing, insulation resistance measurement, winding resistance checks, and dielectric tests such as induced voltage and AC withstand. Functional tests on OLTC, cooling systems, protection relays, and monitoring devices ensure proper operation. Additional assessments—such as oil dielectric strength, temperature-rise simulation, and noise level measurement—confirm the transformer’s durability, safety, and performance. These comprehensive FAT procedures guarantee reliable service in grid and substation applications.

Routine Test - Lightning Impulse

Check all terminals and connections to ensure they are secure and free of contamination.

Perform the test under suitable environmental conditions: relative humidity less than 75%, temperature between 20-30°C, no rain.

Current waveform Impedance

Reaction voltage waveform

Ambient temperature and humidity during testing

The voltage waveform meets the standard requirements, and the equipment does not have abnormal discharge or local breakdown: good

Obvious damage or non-standard waveform during the test: Further inspection or corrective measures are required

Application

Technical Advantages

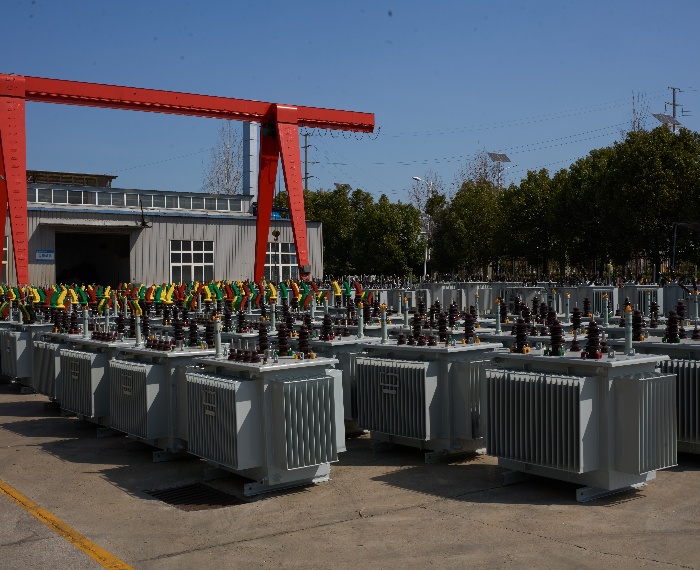

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.